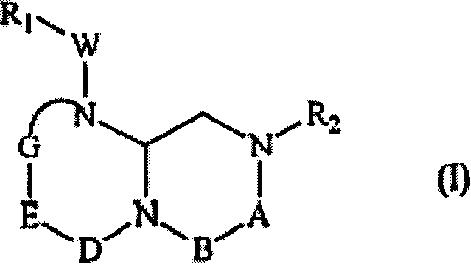

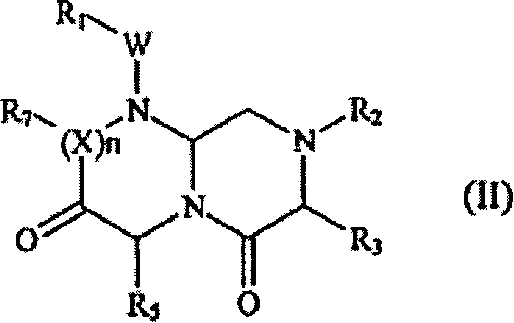

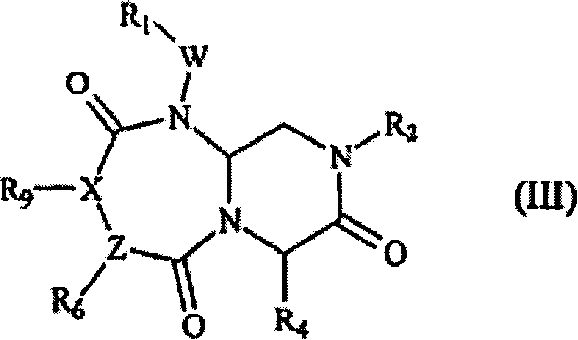

Reverse-turn mimetics and method relating thereto

A technology of alkyl and compound, which is applied in the field of back-turning mimic structure and its related compound library, which can solve the problems of easy deformation and difficult biological application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0790] (N-Fmoc-N'-R 3 -Preparation of -hydrazino)-acetic acid

[0791] (1) Preparation of N-Fmoc-N'-methylhydrazine

[0792]

[0793] A 2L two-neck round bottom flask was fitted with a glass stopper and calcium tube. Add methylhydrazine sulfate (20g, 139mmol, wherein R 3is methyl) in THF (300 mL), and DiBoc (33 g, 153 mmol) in THF was added. Over 2 hours, saturated aqueous sodium bicarbonate (500 mL) was added dropwise from an addition funnel with vigorous stirring. After 6 hours, a THF solution of Fmoc-Cl (39 g, 153 mmol) was added slowly. The resulting suspension was stirred at 0°C for 6 hours. The mixture was extracted with ethyl acetate (EA, 500 mL), and the organic layer was retained. The solution was dried over sodium sulfate and evaporated in vacuo. Proceed to the next step without purification.

[0794] Fit a 1L two-neck round bottom flask with a glass stopper and calcium tube. A solution of the product from the previous step in MeOH (300 mL) was...

preparation Embodiment 2

[0803] (N-Moc-N'-R 7 -Preparation of -hydrazino)-acetic acid

[0804] (1) Preparation of (N'-methoxycarbonyl-hydrazine) ethyl acetate

[0805]

[0806] MOC-NH-NH 2 (50 g, 0.55 mol) was dissolved in DMF (300 ml), then ethyl bromoacetate (68 ml, 0.555 mol) and potassium carbonate (77 g, 0.555 mol) were added to the reaction vessel. The mixture was heated to 50°C for 5 hours. After the reaction was complete, the mixture was filtered and diluted with EtOAc, then washed with brine (3 times). The crude product was purified by column (eluent: Hex / EtOAc=4 / 1) to obtain 72 g of colorless oil.

[0807] (2)[N-R 7 -N'-methoxycarbonyl-hydrazino]-ethyl acetate

[0808]

[0809] Ethyl ester (10g, 0.05mol), potassium carbonate (6.9g, 0.05mol) and R 7 - Bromine (14.1 g, 0.06 mol) was dissolved in DMF (200 ml), and the mixture was heated to 50° C. for 5 hours. After the reaction was complete, the mixture was filtered and diluted with EA, then washed with brine (3 ti...

Embodiment 1

[0814]

[0815] (1)N β -Moc-N α - Preparation of benzyl-hydrazinoglycine

[0816]

[0817] The compounds were prepared according to literature procedures. (Cheguillaume et al., Synlett 2000, 3, 331).

[0818] (2) 1-methoxycarbonyl-2,8-dibenzyl-6-methyl-4,7-dioxo-hexahydro-pyrazino[2,1-c][1,2,4] Preparation of triazines

[0819] Bromoacetal resin (60 mg, 0.98 mmol / g) and benzylamine in DMSO (2.5 ml, 2M) were placed in a vial fitted with a screw cap. The reaction mixture was shaken at 60°C for 12 hours using a rotary oven [Robbins Scientific]. The resin was collected by filtration and washed with DMF and then DCM to give the first fraction.

[0820] A solution of Fmoc-alanine (4 equiv, commercially available, second component fragment), HATU (PerSeptiveBiosystems, 4 equiv) and DIEA (4 equiv) in NMP (Advanced ChemTech) was added to the resin. After shaking the reaction mixture at room temperature for 4 hours, the resin was collected by filtration and washed with DMF,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com