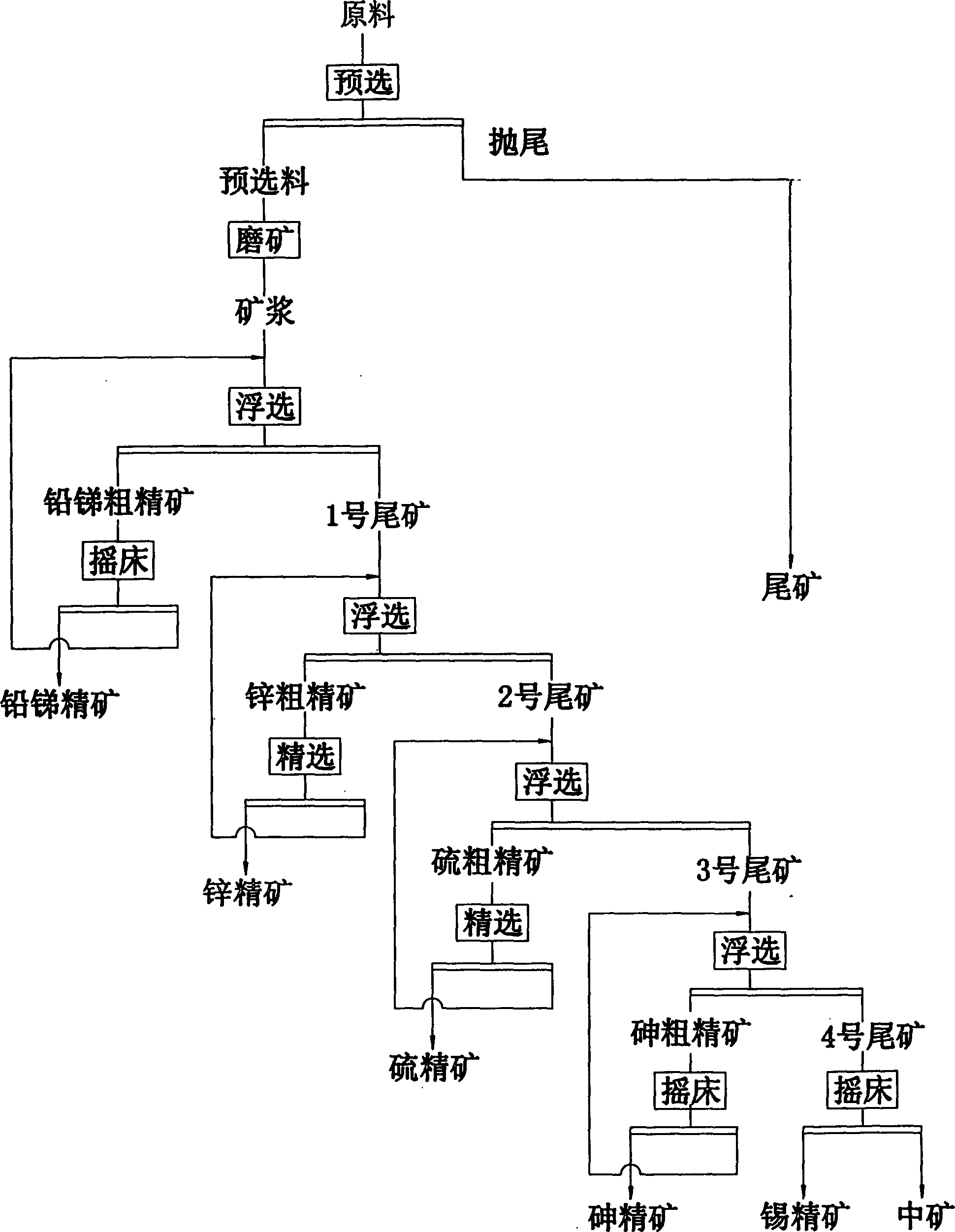

Method for reclaiming valuable mineral from concentrated tailings of stannum-contained multi-metal sulphide ore

A multi-metal and sulfide ore technology, applied in the fields of zinc, arsenic, lead-antimony, reclaimed tin, and sulfur, can solve the problems of undeveloped utilization, achieve good economic benefits, and eliminate hidden dangers of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: The raw material is the tailings of the dressing plant of Dachang Mining Bureau, and its composition weight percentage is 0.3%-0.57% of tin, 0.27%-0.4% of lead, 0.15%-0.21% of antimony, 2.44%-3.27% of zinc, Sulfur 5.7%-9.53%, arsenic 0.87%-1.24%;

[0023] Use a sieve to divide the raw materials into two grades of -3+0.45mm and -0.45mm, use a dynamic sieve jig to sort and throw tails at -3+0.45mm, and use a spiral chute to sort and throw tails at -0.45mm, which can discard the yield It is 46.66% tailings, which improves the selection grade. After the tailings are thrown, the coarse concentrate particle size is -3+0mm, all of which are put into the ball mill for grinding. Sodium and lime 2:1 to adjust the slurry pH to 11, add zinc sulfate 450g / t, potassium cyanide 120g / t, sodium hypocyanate 150g / t to inhibit zinc minerals, then add 25# black medicine 120g / t, B Sulfur nitrogen 100g / t is used as a collector for lead and antimony, and foaming agent 2# oil 40g / ...

Embodiment 2

[0028] Example 2: The raw material is cassiterite polymetallic sulfide ore dressing tailings from Changpo Mineral Concentrator of Guangxi Huaxi Group, and the weight percentage of raw material components is Sn 0.57%, Pb 0.22%, Zn 3.27%, Sb 0.15%, S 5.70% , As 0.87%, SiO 2 40.95%, Fe 10.62%, CaO 13.18%, Al 2 o 3 5.60%, Mg 1.50%;

[0029] Use a sieve to screen the tailings into -3+0.45mm and -0.45 two grades, use a dynamic sieve jig to sort and throw tails at -3+0.45mm, and use a spiral chute to sort and throw tails at -0.45mm, which can be discarded The tailings with a rate of 41.74% have improved the selected grade;

[0030] After discarding the tailings, the particle size of the coarse ore concentrate is -3+0mm, all of which are put into the grinding machine, using appropriate ball diameter and reasonable ball diameter ratio, precise ball diameter, and reasonable force for selective grinding. The grinding particle size is - 200 mesh accounts for 94.4% into flotation;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com