Ozone decolorization method for waste leftover cloth

A fabric and waste technology, which is applied in the field of ozone decolorization of waste and corner fabrics, can solve the problems of high decolorization cost, human harm, and low decolorization efficiency, and achieves the effect of reducing labor intensity, simple operation, and realizing mechanization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

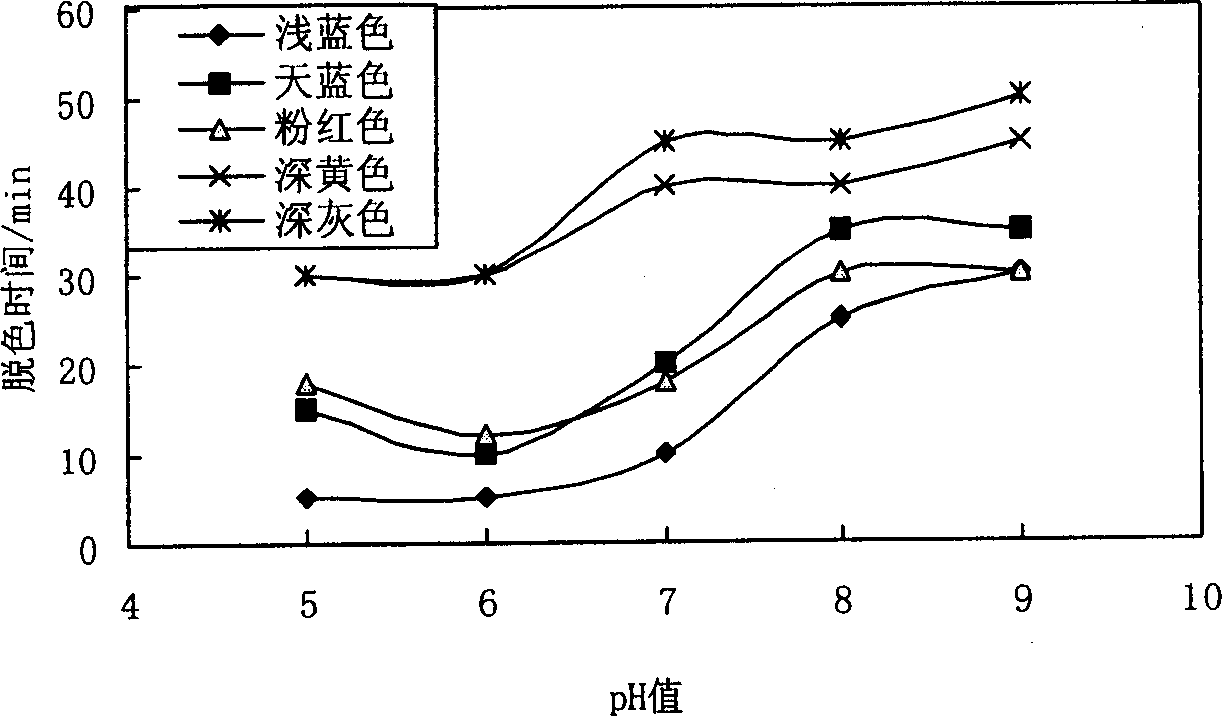

[0057] Example 1: Research on the decolorization time-pH value relationship of light blue, sky blue, pink, dark yellow, dark gray, and purplish red fabrics

[0058] When pH=5, the light blue cloth will turn white soon after directly injecting ozone, and the sky blue and pink cloths will also start to fade in 5 minutes, and the sky blue cloth will turn white in 15 minutes. The pink cloth also faded completely afterwards. The purplish red cloth has a slow decolorization speed because the color is too dark. With the continuous introduction of ozone, the dark yellow cloth and dark gray cloth are almost white in 30 minutes. However, at 60 minutes, some maroon cloth remained. When pH=6, 7, 8, 9, the test rules are basically similar

[0059] When pH=6, the time used for the cloth of various colors to achieve complete decolorization is the shortest.

Embodiment 2

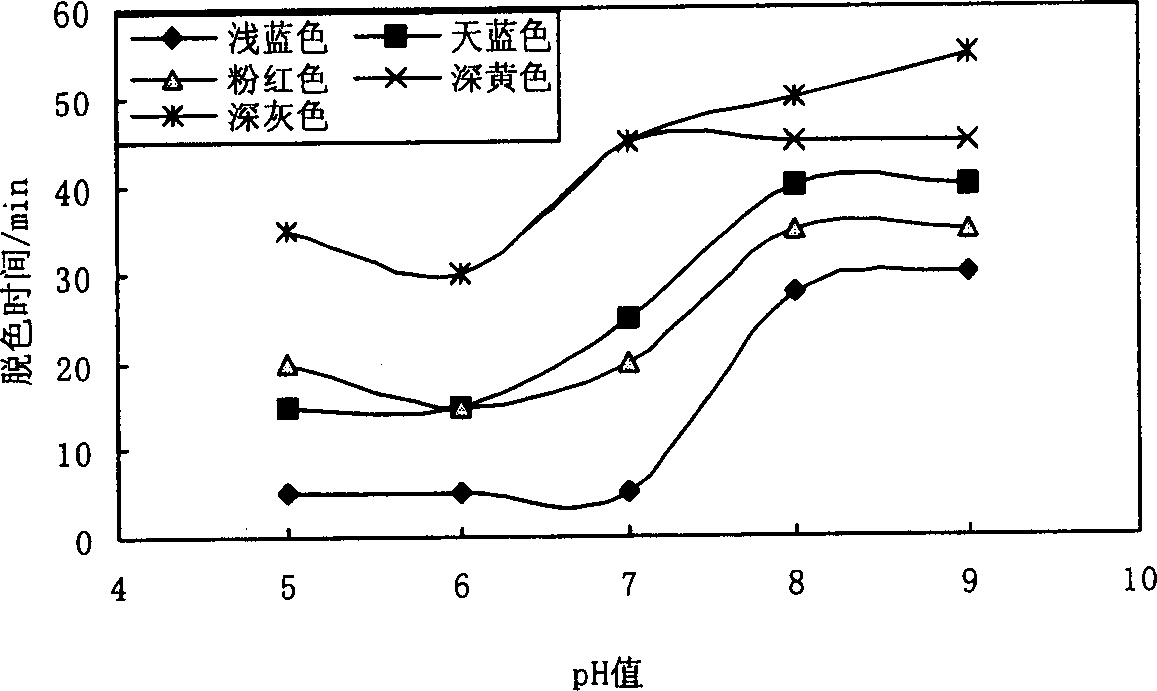

[0060] Example 2: Research on the decolorization time-pH index relationship when these several color cloths of light blue, sky blue, pink, deep yellow, dark gray and purplish red are completely decolorized

[0061] When the ozone flow rate Q=2L / min, put the cloths of the above six colors into the water, adjust the pH value with 10% sodium hydroxide solution and 0.1mol / L sulfuric acid solution, and directly feed the ozone, observe Phenomenon.

[0062] Cloths of various colors are much better under acidic conditions than under alkaline conditions. It seems that the decolorization effect is the best when pH=6. Under mild conditions, the decolorization effect of dark yellow cloth is better than that of dark gray cloth.

Embodiment 3

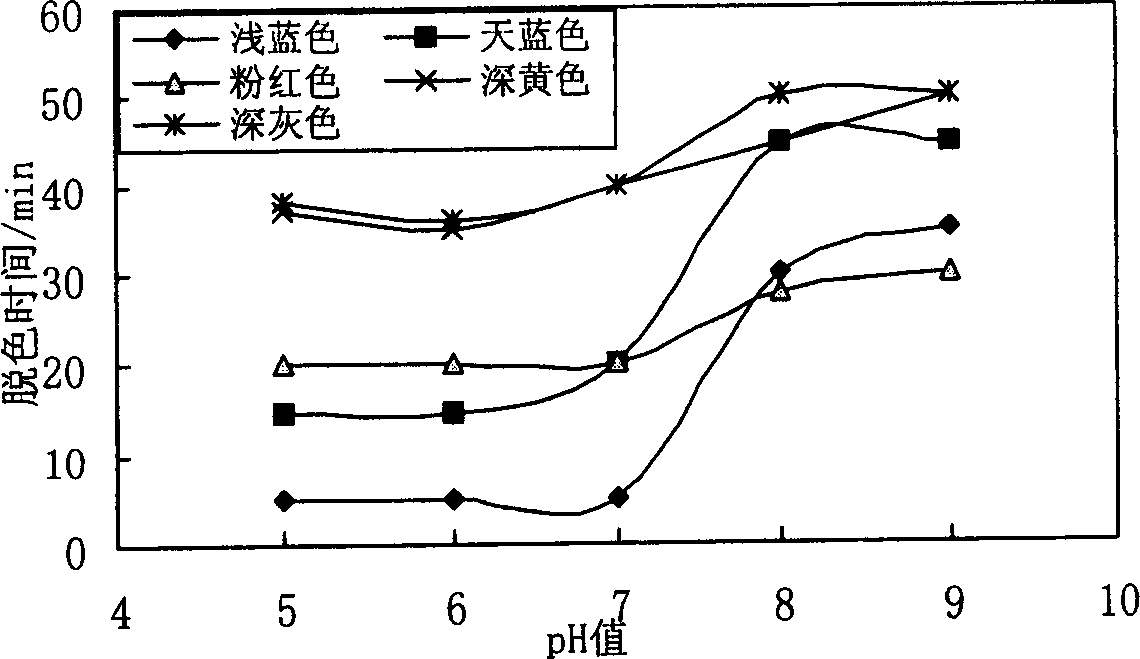

[0063] Embodiment 3: when the decolorization time of these several color cloths of light blue, sky blue, pink, deep yellow, dark gray, burgundy red -pH refers to the ozone flow rate Q=3L / min, get the cloth of above six kinds of colors and put into water, Use 10% sodium hydroxide solution and 0.1mol / L sulfuric acid solution to adjust the pH value, directly pass through ozone, and observe the phenomenon.

[0064] Under acidic conditions, the decolorization time of various colors of cloth is relatively stable. Light blue can be decolorized into white in 5 minutes under acidic conditions, while when the pH value is 8 or 9, it takes more than 30 minutes to decolorize into white. There is also sky blue, and the decolorization time is 30 minutes apart under acid-base conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com