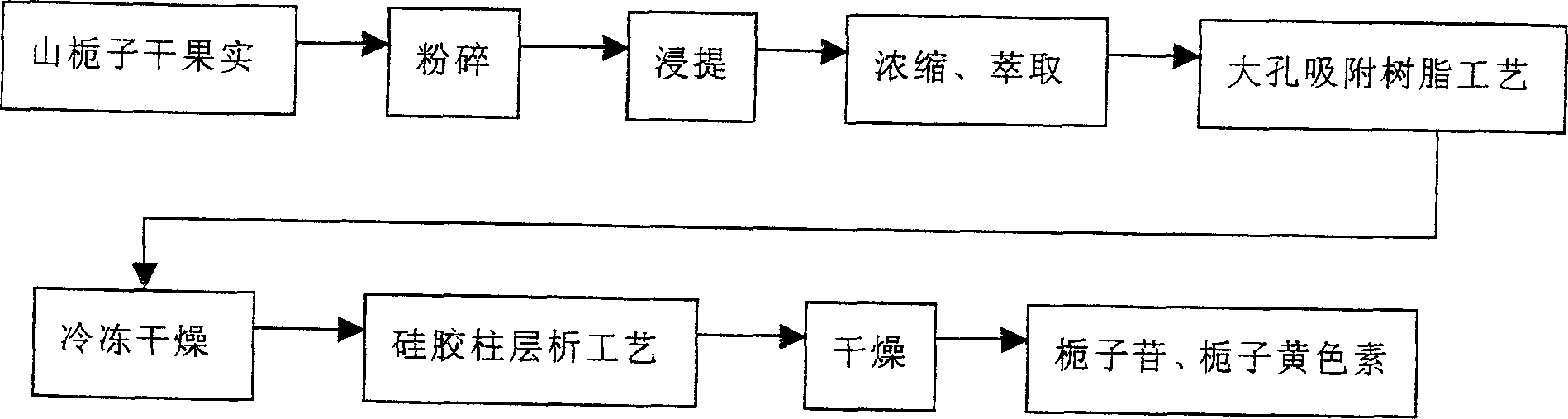

Method for producing high purity jasminoidin and high color number gardenia yellow pigment

A technology of gardenia yellow pigment and purification method, which is applied in the production of high-purity geniposide and the extraction field of high color value gardenia yellow pigment, can solve the problems of low yield and color value of gardenia yellow products, waste of resources, etc. Achieve the effects of tinting strength, high safety, and increased added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment one: total material-liquid ratio is in g / ml by mass / volume:

[0018] In the present invention, the dried gardenia fruit raw material is ground into a powder passing through a 10-mesh sieve through a SF-200C high-speed pulverizer, and 430 g of the dried gardenia fruit powder is accurately weighed, soaked with 60% ethanol solution (weight percentage concentration), wherein the total The ratio of solid to liquid is 1:20, and the extraction is divided into four times, the extraction temperature is 15°C, and the extraction time is 3 hours; the extract is filtered and the alcohol is recovered to obtain 240ml of concentrated solution, and then 240ml of petroleum ether is used to extract and remove impurities three times, 80ml each time . Add the concentrated solution to the macroporous adsorption resin X-5, and use 0%, 10%, 20%, 30%, 35%, 40%, 50%, 60%, 70%, 80%, 95% ethanol in sequence The solution was subjected to gradient elution with an elution volume of 1BV, c...

Embodiment 2

[0022] Embodiment two: total material-liquid ratio is in g / ml by mass / volume:

[0023] Grind the dried fruit of Gardenia jasminoides raw material into a powder passing through a 10-mesh sieve through an SF-200C high-speed pulverizer, accurately weigh 585 g of dried fruit of Gardenia jasmine fruit, soak in distilled water, wherein the total material-to-liquid ratio is 1:25, and soak in 3 times. Extraction, extraction temperature: 30°C, extraction time: 2 hours; filter the extract, concentrate to 340ml, then extract with 340ml petroleum ether to remove impurities, extract three times, 115ml each time; add the concentrated solution to the macroporous adsorption resin X- 5, and carry out gradient elution with distilled water, 10%, 20%, 30%, 35%, 40%, 50%, 60%, 70%, 80%, 95% ethanol solution (weight percent concentration) successively, wash The volume of removal is 1BV, collected in sections, and a small sample is diluted 500 times with distilled water, the absorbance value is meas...

Embodiment 3

[0026] Embodiment three: total material-liquid ratio is in g / ml by mass / volume:

[0027] Grind the dried gardenia fruit raw material into a powder with a 10-mesh sieve through a SF-200C high-speed pulverizer, accurately weigh 500 g of the dried gardenia fruit powder, soak it with 70% ethanol solution (weight percentage concentration), and wherein the total feed liquid Ratio 1:20, extract in four times, extraction temperature: 20°C, extraction time: 4 hours; filter the extract, recover alcohol and concentrate to 300ml, then use 300ml petroleum ether to extract and remove impurities three times, 100ml each time; The concentrated solution was added to the macroporous adsorption resin X-5 (the following conditions are the same as in Example 1).

[0028]The corresponding geniposide fraction was collected, concentrated to 160ml by rotating vacuum, then frozen to -70°C, and vacuum-dried (the absolute vacuum degree: 0.05Mpa, the drying temperature: -40°C, and the drying time: 80 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com