Thin film supporting substrate used in filter for hydrogen production and method for manufacturing filter for hydrogen production

A manufacturing method and filter technology, applied in chemical instruments and methods, using solid contact hydrogen separation, membrane technology, etc., can solve the problems of inability to fully exert the durability of the filter, the difficulty of avoiding the deterioration of the adhesive, and the hydrogen permeation efficiency Obstacles and other problems, to achieve the effect of improving hydrogen permeation efficiency, improving hydrogen permeation efficiency, and large hydrogen permeation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

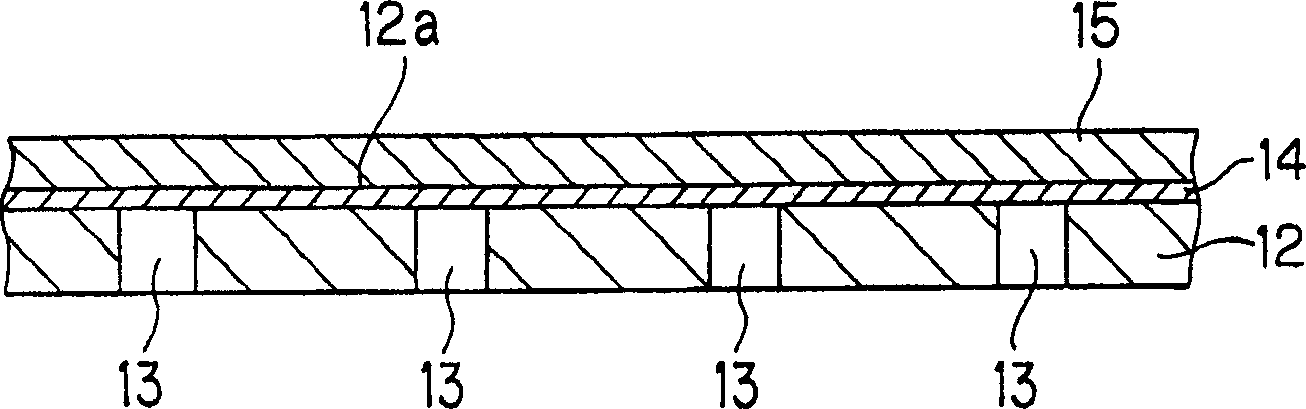

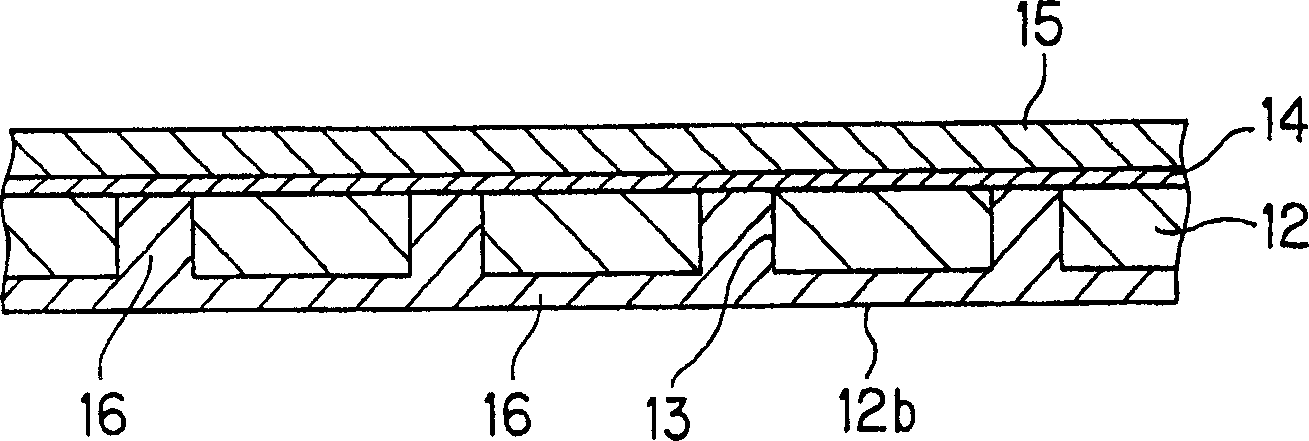

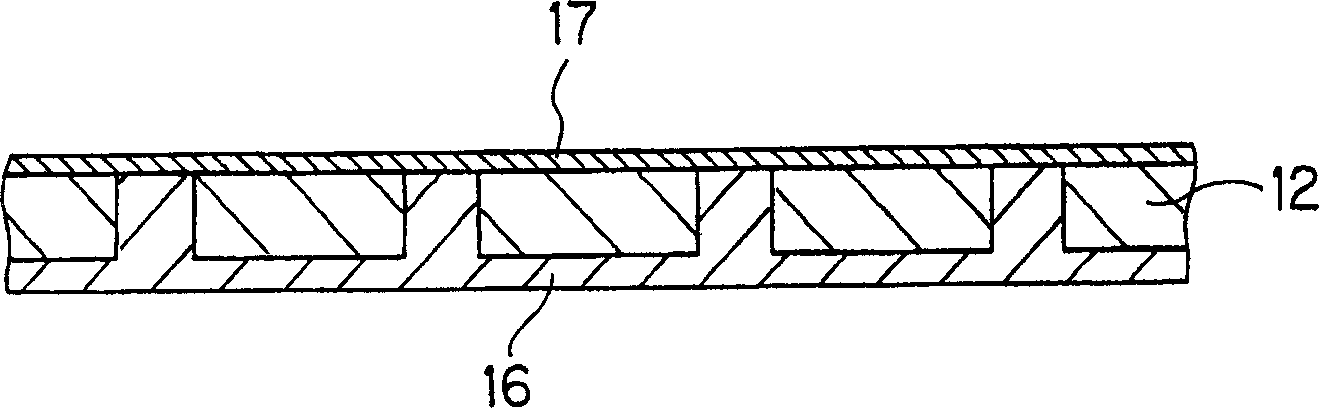

[0106] Fabrication of filters for hydrogen production

[0107] Prepare a SUS430 material with a thickness of 50 μm as a base material, and apply a photosensitive resist material (OFPR manufactured by Tokyo Ohka Industry Co., Ltd.) (film thickness 7 μm (when dry)) to both sides of the SUS430 material by dipping method, Next, a photomask in which a plurality of circular openings having an opening size (opening diameter) of 120 μm is arranged at a pitch of 200 μm is placed on the above-mentioned resist coating film, and the resist coating is applied through the photomask. The film was exposed and developed using sodium bicarbonate solution. In this way, a resist pattern having a circular opening with an opening size (opening diameter) of 120 μm was formed on both surfaces of the SUS430 material. In addition, the centers of the openings of the resist patterns formed on the respective surfaces were made uniform by the SUS430 material.

[0108]Then, using the above resist pattern ...

Embodiment 2

[0135] Fabrication of filters for hydrogen production

[0136] A SUS304 material with a thickness of 50 μm was prepared as a base material, and a photosensitive resist material (OFPR manufactured by Tokyo Ohka Kogyo Co., Ltd.) was applied (film thickness 7 μm (when dry)) to both sides of the SUS304 material by a dipping method. Next, a photomask in which a plurality of circular openings having an opening size (opening diameter) of 120 μm is arranged at a pitch of 200 μm is placed on the above-mentioned resist coating film, and the resist coating is applied through the photomask. The film was exposed and developed using sodium bicarbonate solution. In this way, a resist pattern with circular openings having an opening size (opening diameter) of 120 μm was formed on both surfaces of the SUS304 material. In addition, the centers of the openings of the resist patterns formed on the respective surfaces were made uniform by the SUS304 material.

[0137] Next, using the above resis...

Embodiment 3

[0160] Fabrication of filters for hydrogen production

[0161] In the same manner as in Example 2, a plurality of through holes were formed in the SUS304 material to obtain a conductive base material.

[0162] Next, Ni strike plating (thickness: 0.01 μm) was performed on the above-mentioned SUS304 material under the following conditions, and then resin parts (AZ111 manufactured by Shipley Co., Ltd.) were filled in the through-holes of the above-mentioned SUS304 material. The filling of these resin parts is carried out by means of grouting. (The above is the filling process)

[0163] (Conditions for Ni strike plating)

[0164] ·Electroplating solution composition: nickel chloride ...... 300g / L

[0165] Boric acid ...... 30g / L

[0166] PH: 2

[0167] ·Liquid temperature: 55~65℃

[0168] ·Current density: 10A / dm 2

[0169] Next, the following pretreatment is performed on one surface of the SUS304 material filled with the resin component in the through hole, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com