Preparation technology of phosphorus nitrogen series expansion type fire retardant

An intumescent flame retardant and preparation technology, which is applied in the direction of fireproof coatings, etc., can solve the problems of poor compatibility of polyolefins, high hygroscopicity, synthesis yield and environmental protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

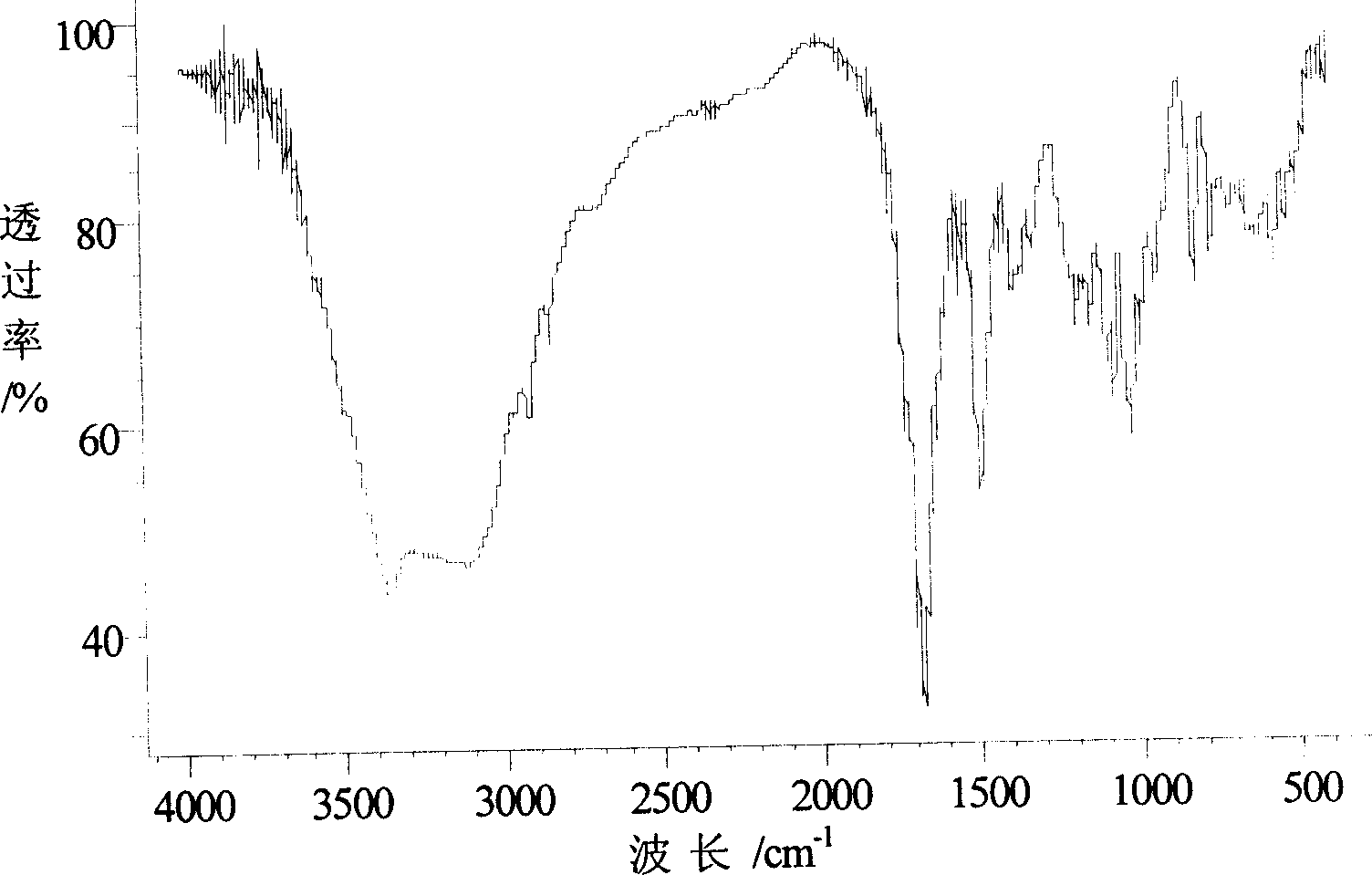

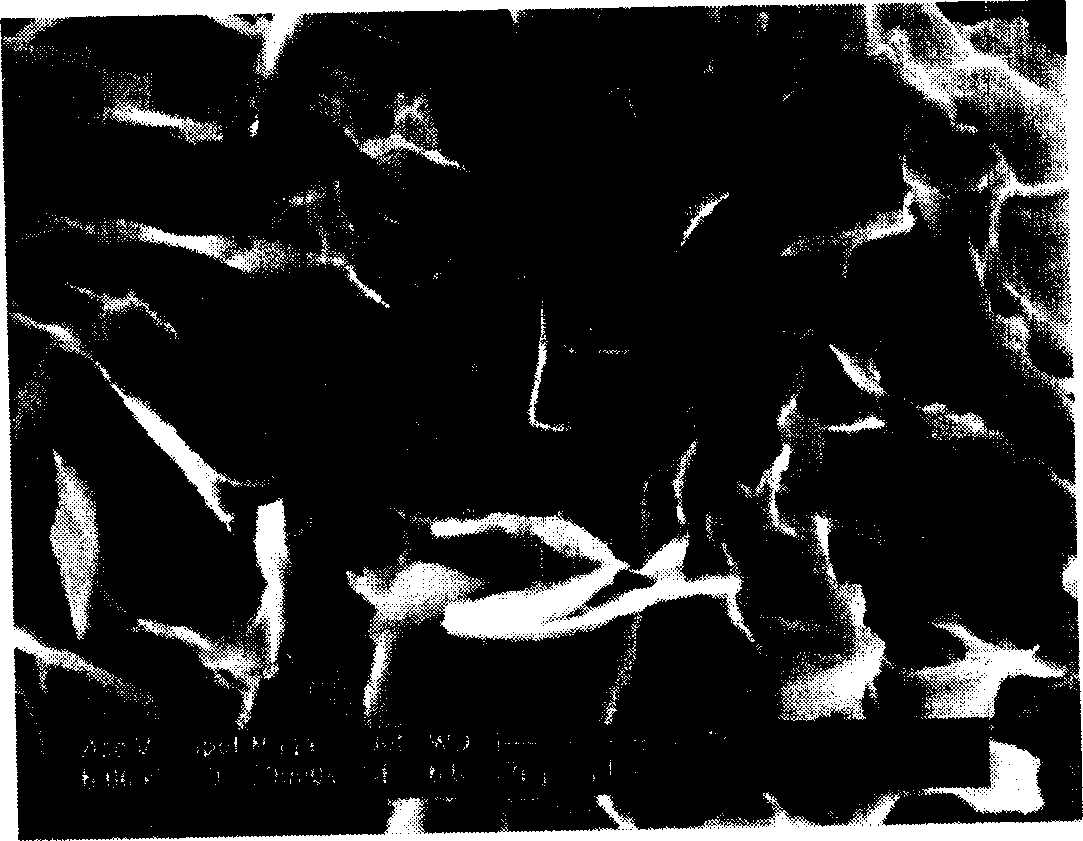

Embodiment 1

[0025] Add 68g of pentaerythritol and 250ml of phosphorus oxychloride into a 500ml three-neck flask, place in an oil bath at 110°C, stir vigorously for 24 hours, and absorb the hydrogen chloride gas produced by the reaction with NaOH aqueous solution. After the reaction was completed, it was cooled with an ice-water bath, filtered under reduced pressure, washed with dichloromethane, and the filtrate was vacuum-dried at room temperature (20° C.) for 6 hours to obtain a white solid powder (yield 76%). Take 29.7g of the white solid powder and dissolve it in a three-neck flask filled with 250ml of water, place it in a water bath at 90°C, stir and react for 0.5 hours, then add 100ml of 2mol / L NaOH aqueous solution dropwise, the dropping time is 1 hour, add dropwise Continue to react for 10 minutes after completion. Then add 25.2 g of melamine, add 1 g of sodium stearate after reacting for 1 hour, and continue to stir and reflux for 1 hour. After the reaction, cool with an ice-wate...

Embodiment 2

[0028] Add 68g of pentaerythritol and 250ml of phosphorus oxychloride into a 500ml three-neck flask, place in an oil bath at 110°C, stir vigorously for 24 hours, and absorb the hydrogen chloride gas produced by the reaction with NaOH aqueous solution. After the reaction was completed, it was cooled with an ice-water bath, filtered under reduced pressure, washed with dichloromethane, and the filtrate was vacuum-dried at room temperature (20° C.) for 6 hours to obtain a white solid powder (yield 76%). Take 29.7g of the white solid powder and dissolve it in a three-necked flask filled with 250ml of water, place it in a water bath at 90°C, stir and react for 0.5 hours, then add 2mol / L NaHCO dropwise 3 The aqueous solution was 100ml, and the dropwise addition time was 1 hour, and the reaction was continued for 10 minutes after the dropwise addition was completed. Then add 25.2 g of melamine, add 1 g of sodium stearate after reacting for 1 hour, and continue to stir and reflux for 1...

Embodiment 3

[0030] Add 68g of pentaerythritol and 250ml of phosphorus oxychloride into a 500ml three-neck flask, place in an oil bath at 110°C, stir vigorously for 24 hours, and absorb the hydrogen chloride gas produced by the reaction with NaOH aqueous solution. After the reaction was completed, it was cooled with an ice-water bath, filtered under reduced pressure, washed with dichloromethane, and the filtrate was vacuum-dried at room temperature (20° C.) for 6 hours to obtain a white solid powder (yield 76%). Take 29.7g of the white solid powder and dissolve it in a three-neck flask filled with 250ml of water, place it in a water bath at 90°C, stir and react for 0.5 hours, then add 100ml of 2mol / L NaOH aqueous solution dropwise, the dropping time is 1 hour, add dropwise Continue to react for 10 minutes after completion. Next, 25.2 g of melamine was added, and after 1 hour of reaction, 1 g of sodium dodecylbenzenesulfonate was added, and the stirring and reflux reaction was continued for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com