Method for recovering hydrochloric acid and copper sulfate from acidic etching liquid

A technology of acid etching liquid and acid etching waste liquid, which is applied in the field of recycling useful resources, can solve problems such as poor economic benefits and environmental protection, and achieve the effects of extensive practical value, quick results, and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

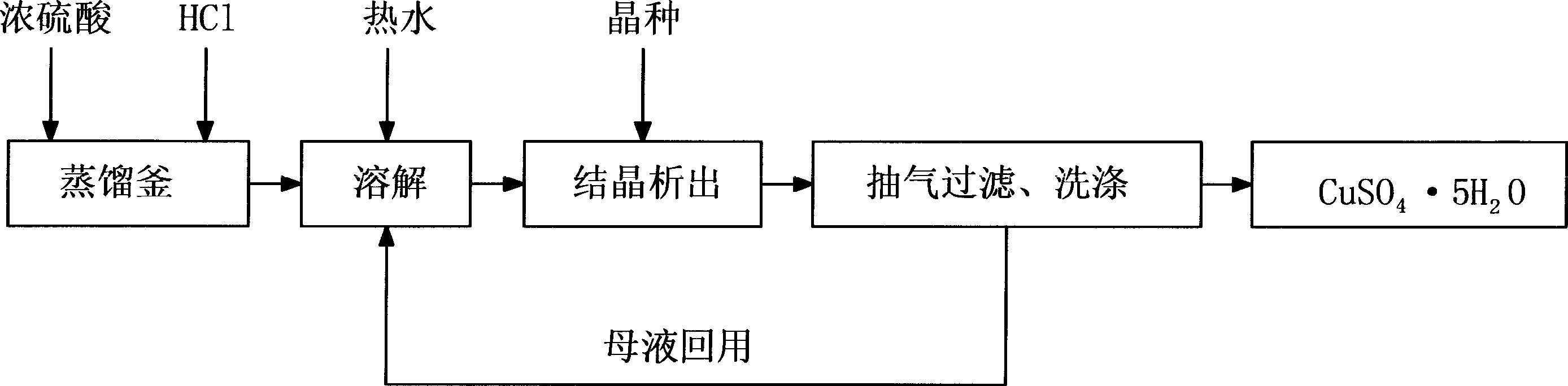

Method used

Image

Examples

Embodiment 1

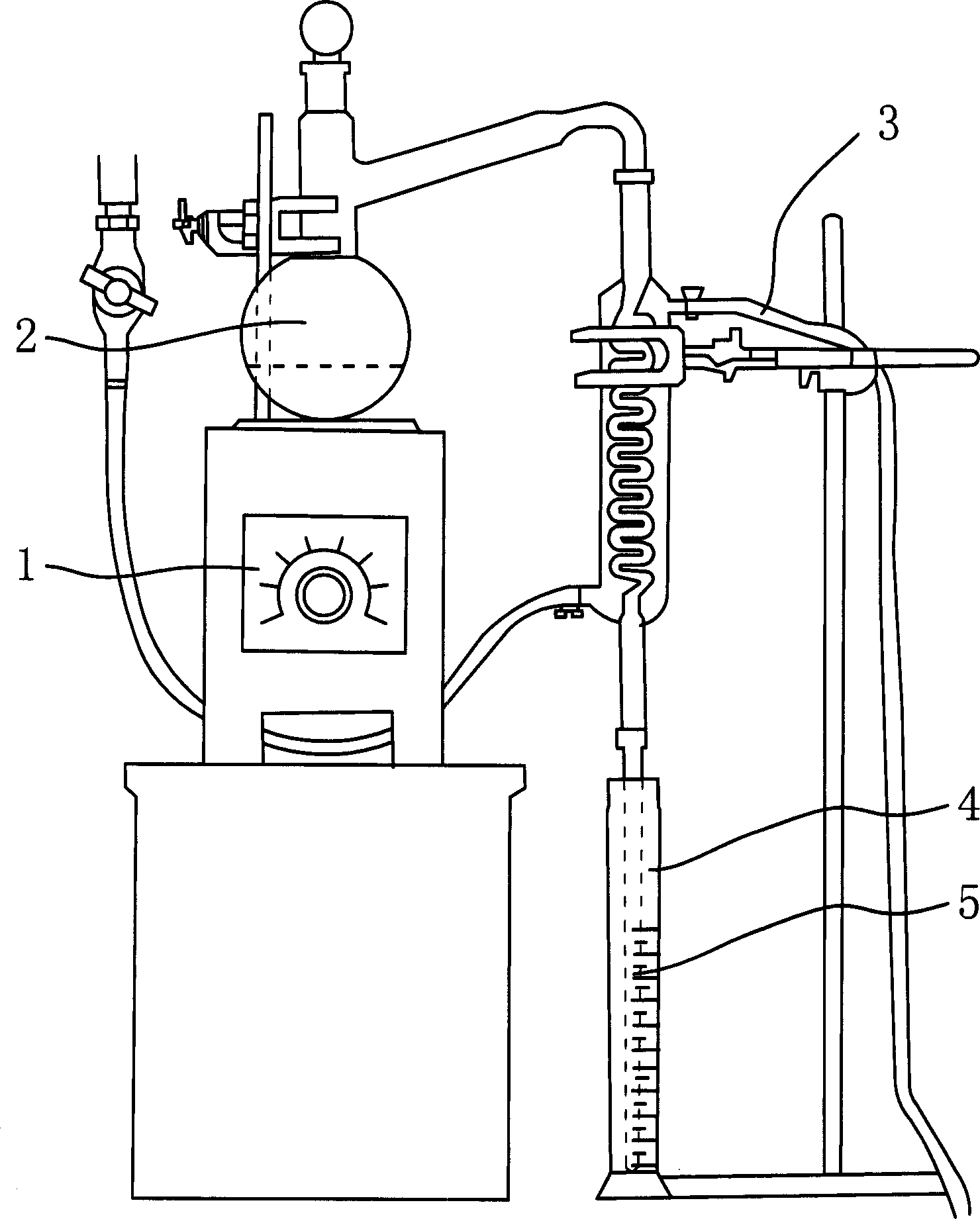

[0051] Embodiment one: a kind of method (laboratory small test) of reclaiming hydrochloric acid and copper sulfate from acid etching solution

[0052] 1. Main reagents and instruments

[0053] 1. Concentrated sulfuric acid 98% AR grade

[0054] 2. 500ml full glass still (500ml distillation bottle, 20cm long serpentine condenser)

[0055] 3. 600W or 800W adjustable electric furnace

[0056] 4. 100ml measuring cylinder

[0057] 5. WFX-130 atomic absorption spectrophotometer, used to measure iron, lead, chloride ion and other impurities

[0058] 6. The distillation device is shown in the figure:

[0059] 2. Recycling operation

[0060] 1. Distillation. Take 100ml of acidic etching solution containing 139g / L copper and about 10% hydrochloric acid and pour it into a full glass retort, then add 14ml concentrated sulfuric acid and a few glass beads to prevent the liquid from bumping. according to figure 2 As shown, install the distillation device and start heating and distilla...

Embodiment 2

[0067] Embodiment two: a kind of method (suitable for industrialized production) of reclaiming hydrochloric acid and copper sulfate from acid etching solution

[0068] 1. Distillation kettle

[0069] Enameled or rigid polyvinyl chloride stills are available. The pipe can be made of graphite pipe. For the convenience of operation, three pipes can be inserted into the distillation kettle, which are respectively used for passing steam, adding concentrated sulfuric acid and adding distilled water.

[0070] 2. Recovery of hydrochloric acid

[0071] Put the acidic etching waste liquid in an acid-resistant distillation pot, then add concentrated sulfuric acid, heat to a slight boiling state, turn on the stirrer to stir, and distill and recover hydrochloric acid at the same time.

[0072] The concentration of concentrated sulfuric acid is 98%. After adding concentrated sulfuric acid to the acidic etching waste liquid, the temperature of the reactor can reach more than 40 degrees in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com