Cosmetic patch and using method thereof, and cosmetic patch package

A technology of patches and oxyalkylene chains, which is applied in pharmaceutical formulations, cosmetic preparations, cosmetics, etc., can solve problems such as reduced adhesion, discoloration, and deterioration of vitamins, and achieve the effect of reducing pigmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

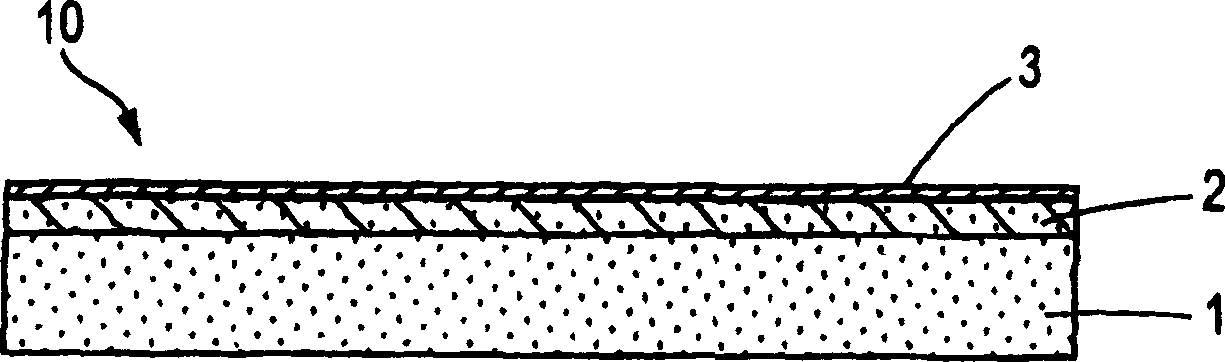

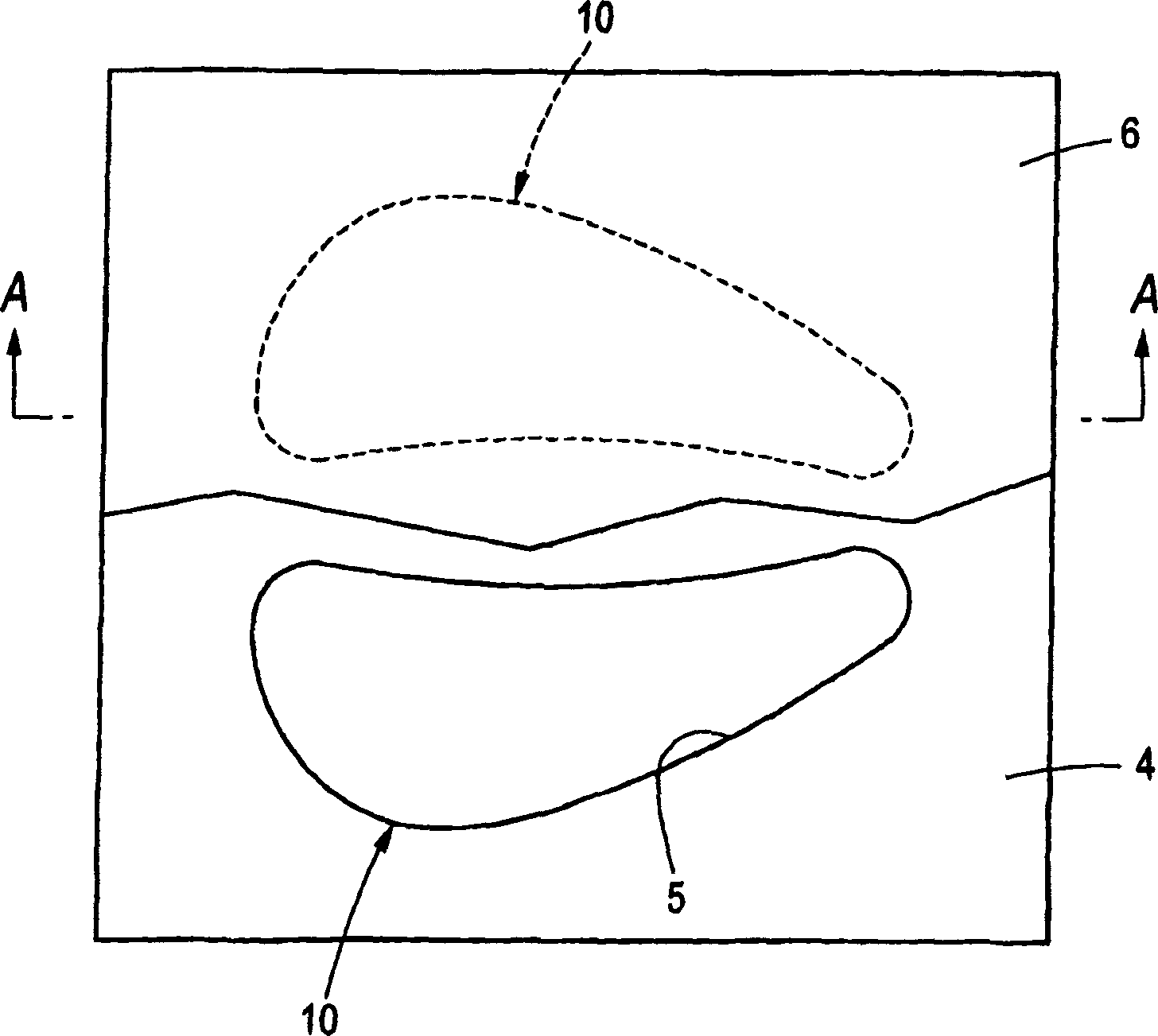

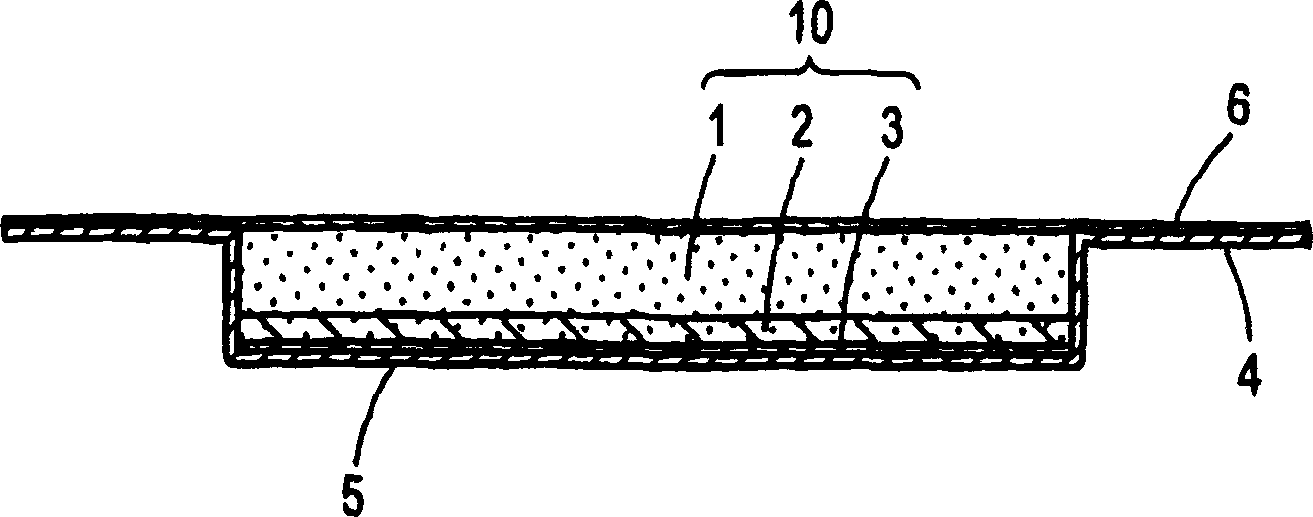

[0250] Molded using polyethylene terephthalate figure 2 tray as shown in the illustration. The polyolefin film and have 40g / m 2 The basis weight polyester nonwoven was heat laminated and the resulting laminate was placed on the bottom of the tray with the nonwoven facing up.

[0251] The polyols and polyisocyanates and catalysts each having the structure, molecular weight and oxyalkylene segment corresponding to the reference symbol of the structural formula as described in Table 1 are mixed in the ratio as described in Table 1, and the mixture is added dropwise to note Grooves for full pallets. By reacting at 60° C. for a predetermined time, a gel layer of urethane gel having the nonwoven fabric and the polyolefin film laminated on the bottom surface while having the nonwoven fabric embedded in the surface layer of the bottom surface was formed.

[0252] A water / ethanol solution of vitamin C was added dropwise to the upper surface of the gel layer to introduce vitamin C t...

Embodiment 2

[0260] As in Example 1, the polyolefin film and the nonwoven fabric were thermally laminated, and the resulting laminate was placed in the grooves of a tray made of polyethylene terephthalate. Mix polyols and polyisocyanates and catalysts each having a structure, molecular weight, and oxyalkylene segment corresponding to the reference symbol of the structural formula as described in Table 2, and mix them in a ratio as described in Table 2, and fill the recesses of the tray with the mixture. groove. By reacting at 60° C. for a predetermined time, a gel layer of urethane gel having the nonwoven fabric and the polyolefin film laminated on the bottom surface while having the nonwoven fabric embedded in the surface layer of the bottom surface was formed.

[0261]

Structural formula (D), R=H, molecular weight: 2000

(AO)=(CH 2 CH 2 O) m (CH(CH 3 )CH 2 O) n

Random copolymer, m:n=30:70

number of copies

100

...

Embodiment 3

[0266] As in Example 1, the polyolefin film and the nonwoven fabric were thermally laminated, and the resulting laminate was placed in the grooves of a tray made of polyethylene terephthalate. The polyols and polyisocyanates and catalysts each having the structure, molecular weight and oxyalkylene segment corresponding to the reference symbols of the structural formula as described in Table 3 were mixed in the ratio as described in Table 3, and the mixture was filled into the recesses of the tray. groove. By reacting at 60° C. for a predetermined time, a gel layer of urethane gel having the nonwoven fabric and the polyolefin film laminated on the bottom surface while having the nonwoven fabric embedded in the surface layer of the bottom surface was formed.

[0267]

Structural formula (D), R=H, molecular weight: 1700

(AO)=(CH 2 CH 2 O) m (CH(CH 3 )CH 2 O) n

Random copolymer, m:n=70:30

number of copies

100

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com