Injection type pH sepsitive chitin quarternary ammonium salt aquagel and its preparation method

A chitosan quaternary ammonium salt, chitosan technology, applied in the directions of pharmaceutical formulations, inactive medical preparations, drug delivery, etc., can solve the problems of patients' economic burden, inconvenience, application barriers, etc. and safety, high pH responsiveness, and the effect of improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

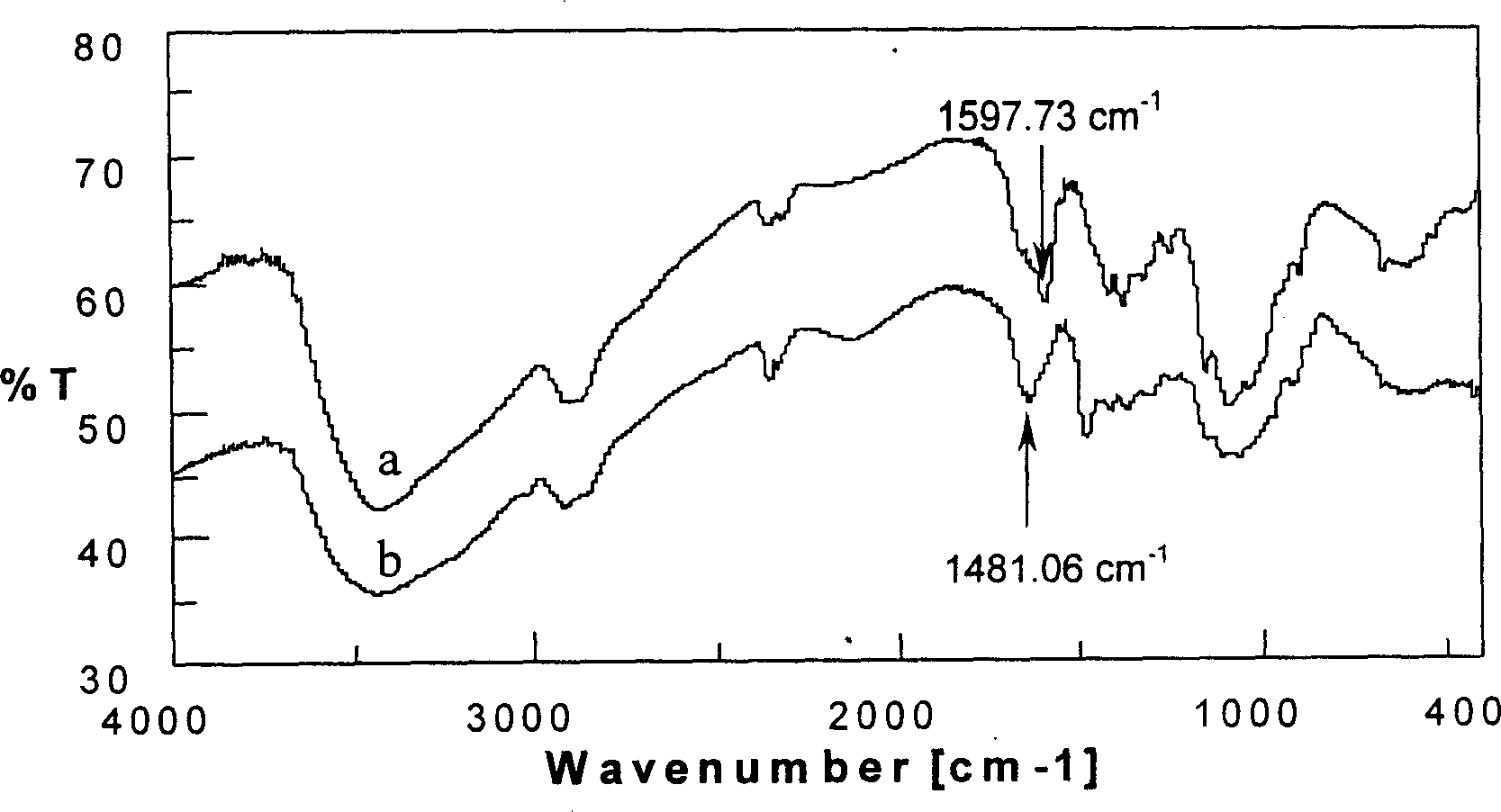

[0049] Disperse 3.0g of chitosan in 20mL of water and stir at 80°C for 1h. 16.94g of 2,3-epoxypropyltrimethylammonium chloride was dissolved in 15mL of water, and added to the chitosan dispersion. After stirring and reacting at 80° C. for 12 h, the reaction solution was poured into acetone to precipitate, stirred and washed in a refrigerator overnight, and then dried to obtain a white loose product. Characterized by infrared spectroscopy (attached figure 1 ), proving that quaternary ammonium groups are substituted on the chitosan chain to generate chitosan quaternary ammonium salts.

Embodiment 2

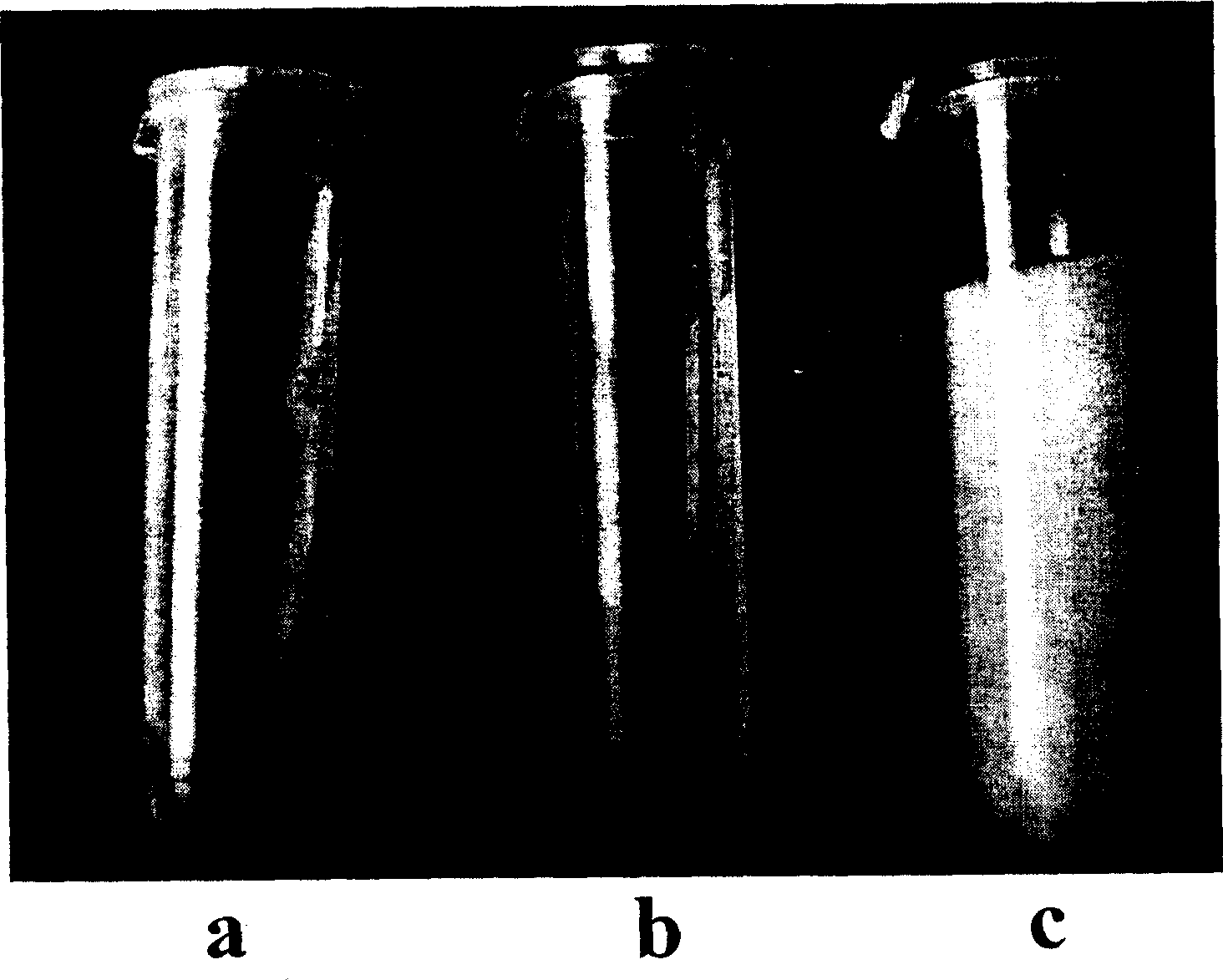

[0051] Dissolve 0.50 g of the chitosan quaternary ammonium salt prepared in Example 1 in the lactic acid solution of 8 mL of 0.1 mol / L, and dissolve completely. Cool to 4°C, add 2 mL of 0.25 g / mL sodium β-glycerophosphate solution dropwise with stirring, and stir well to make it evenly mixed. The pH of the resulting solution was 7.4. The mixed solution was heated to 37°C and kept for 60 minutes to fully gel the system. The system is stable at 4°C. Chitosan quaternary ammonium salt solution, chitosan quaternary ammonium salt-β-sodium glycerophosphate mixed solution, the photo of the chitosan quaternary ammonium hydrogel that gelled under 37 ℃ are as attached figure 2 shown.

Embodiment 3

[0053] Dissolve 0.50 g of the chitosan quaternary ammonium salt prepared in Example 1 in the acetic acid solution of 8 mL of 0.1 mol / L, and dissolve completely. Cool to 4°C, add 2 mL of 0.25 g / mL sodium β-glycerophosphate solution dropwise with stirring, and stir well to make it evenly mixed. The resulting solution had a pH of 7.0. The mixed solution was heated to 37°C and kept for 60 minutes to fully gel the system. The system is stable at 4°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com