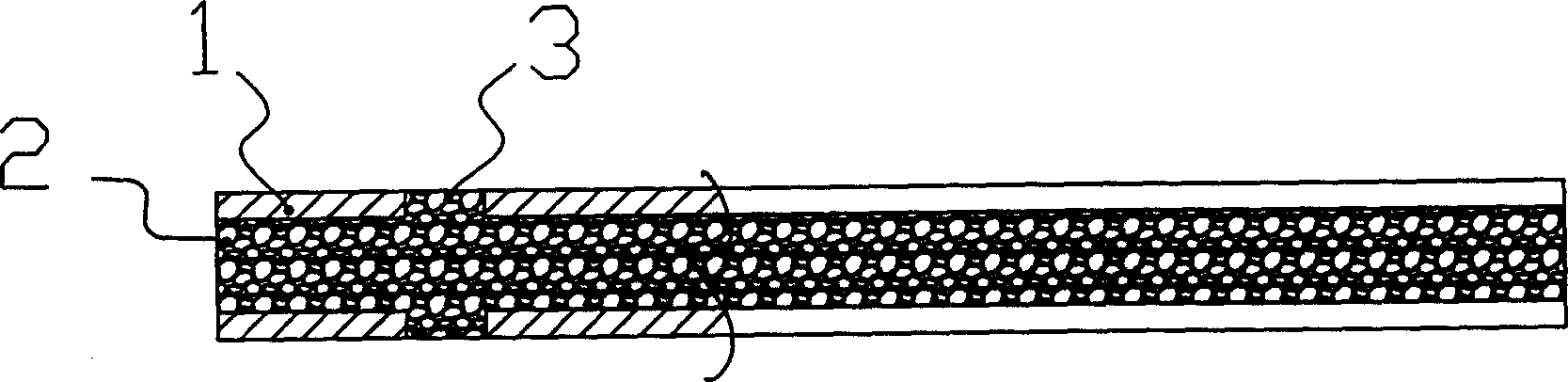

Fire-resistance synthetic wood and its manufacturing method

A technology for synthesizing wood and flame-retardant layers, applied in the direction of manufacturing tools, wood-layered products, chemical instruments and methods, etc., can solve practical problems such as fire prevention, and achieve light weight, good toughness, and strong adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 of the above-mentioned flame-retardant synthetic wood manufacturing process is as follows:

[0038] 1. Process the wood into a veneer with a thickness of 0.5mm;

[0039] 2. Treat the wood veneer with flame retardant, anti-insect and anti-corrosion treatment: After vacuum pressurization, the vacuum degree is 97% (33mvbar) and the pressure is 2.5mpa. After soaking, add flame retardants, insect repellents, and preservatives (the above materials are made of phosphoric acid, boric acid, and dihydroammonia. deployment);

[0040] 3. Enter the dryer to dry the veneer after flame retardant treatment, and the dry humidity of the veneer in the air is controlled at 40-55%:

[0041] 4. The veneer after drying is manually spliced and shaped, and the shape and size are determined according to the market and users;

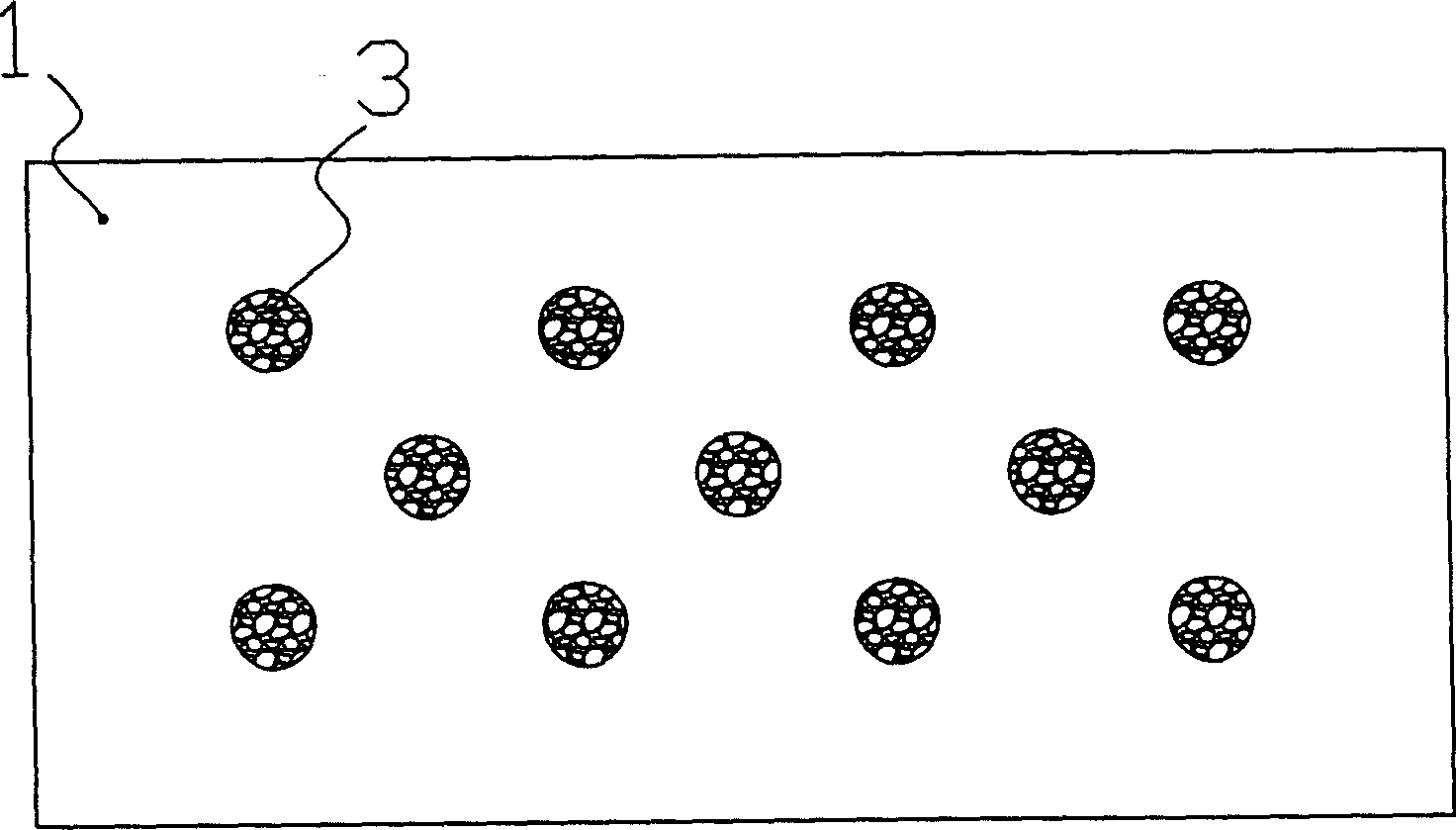

[0042] 5. Put the assembled veneer on the special tool for equidistant or unequal-distance drilling, the aperture is Φ3, and the hole distance is between ...

Embodiment 2

[0049] Embodiment 2 of flame-retardant synthetic wood manufacturing process is as follows:

[0050] 1. The wood is processed into a veneer with a thickness of 10mm;

[0051] 2. Treat the wood veneer with flame retardant, anti-insect and anti-corrosion treatment: After vacuum pressurization, the vacuum degree is 97% (33mvbar) and the pressure is 2.5mpa. After soaking, add flame retardants, insect repellents, and preservatives (the above materials are made of phosphoric acid, boric acid, and dihydroammonia. deployment);

[0052] 3. Enter the dryer to dry the veneer after flame retardant treatment, and the dry humidity of the veneer is controlled at 40-55%;

[0053] 4. The veneer after drying is manually spliced and shaped, and the shape and size are determined according to the market and users;

[0054] 5. Put the assembled veneer on the special tool for equidistant or unequal-distance drilling, the hole diameter is Φ20, the hole distance is between 90mm-100mm; the dry humid...

Embodiment 3

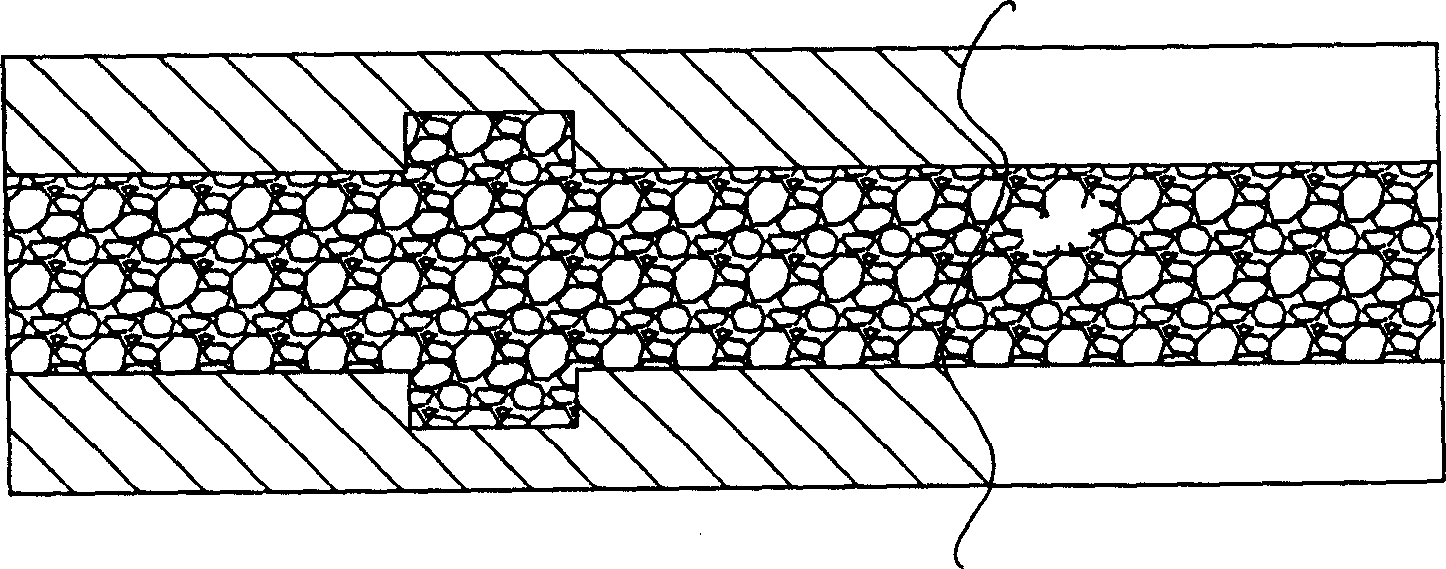

[0061] Embodiment 3 of flame-retardant synthetic wood manufacturing process is as follows:

[0062] 1. The wood is processed into a veneer with a thickness of 0.7mm;

[0063] 2. Treat the veneer with fire-retardant, insect-proof and anti-corrosion treatment;

[0064] 3. Enter the dryer to dry the veneer after flame retardant treatment, and the dry humidity of the veneer is controlled at 40-55%;

[0065] 4. The veneer after drying is manually spliced and shaped;

[0066] 5. Put the assembled veneer on the special tool for equidistant or unequal-distance drilling, the aperture is Φ12, and the hole distance is between 50mm-70mm;

[0067] 6. According to the composition and weight ratio: saw foam or peanut shell powder 125kg; talcum powder 27kg; double fly powder 27kg; perlite 30kg; magnesium chloride 315kg; Make a liquid with a density between 1.4 and 1.5 and mix it with other materials;

[0068] 7. Select a good veneer for the top and bottom, and use incomplete ones in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com