Chemical and machinery pulping process using complete white mulberry branch as raw material

A chemical-mechanical, mulberry branch technology, applied in the directions of pulping with inorganic alkali, pulping with organic solvents, fiber raw materials, etc., can solve the problems of long soaking time, easy accumulation, low pulp yield and strength, etc. The effect of improving the qualified rate of slices, increasing the specific surface area and making full use of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

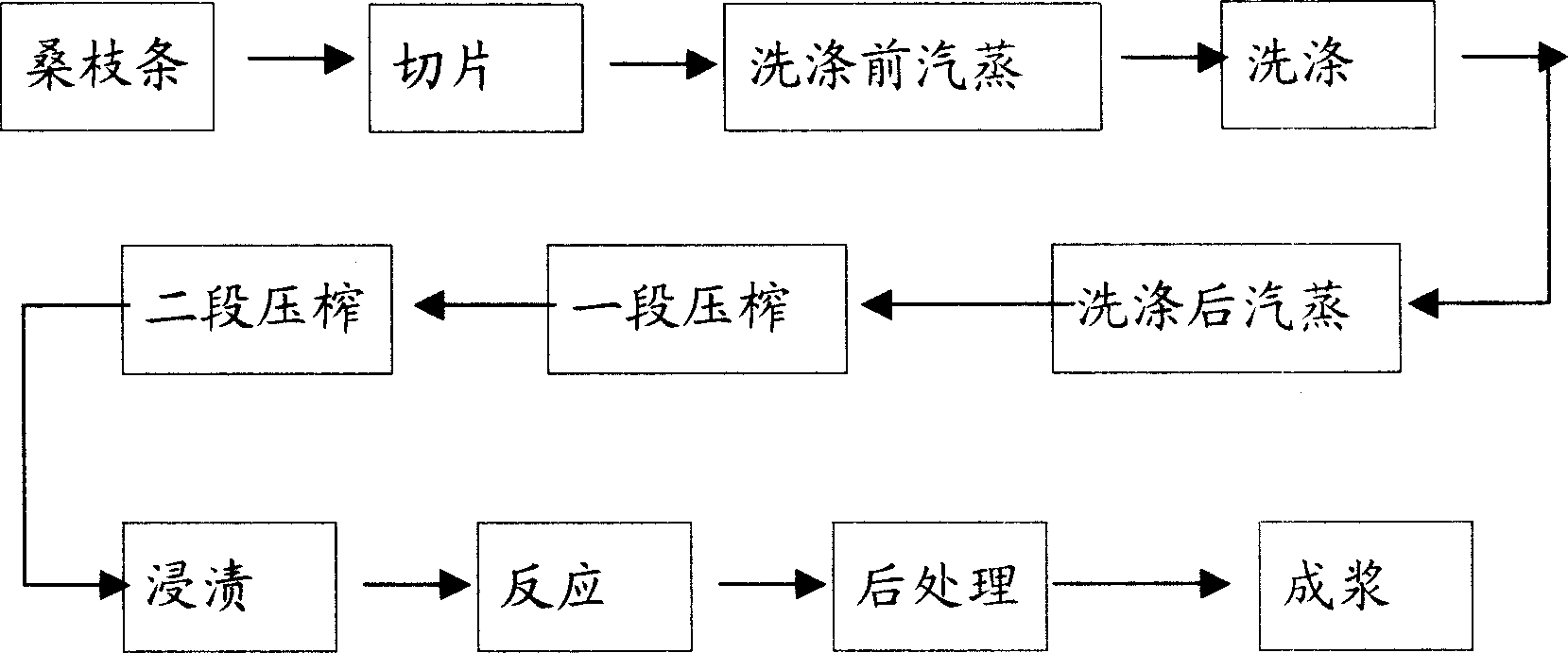

[0038] Embodiment 1: a kind of pulping process using mulberry branch as the chemical mechanical pulp of raw material, carries out as follows:

[0039] (1) slice: mulberry branch is cut into the straight section that length is 10mm;

[0040] (2) Steaming before washing: the above-mentioned straight slices are sent into the steaming chamber, and a sodium hydroxide solution (concentration of 100g / l) of 2% of the straight slice weight (net weight) is added in the steaming chamber. Under the condition of temperature of 60°C, the steaming time is 20 minutes;

[0041] (3) Washing: Wash the steamed straight slices in water at 70°C;

[0042] (4) Steaming after washing: Send the straight slices after washing into the steaming chamber, and steam for about 20 minutes under the condition that the steaming exhaust temperature is 70°C;

[0043] (5) One-stage pressing: Send the steamed straight slices into the first stage of the screw extruder to squeeze, grind and tear them under a pressur...

Embodiment 2

[0048] Embodiment 2: a kind of pulping process using mulberry sticks as raw material chemical mechanical pulp, carried out as follows:

[0049] (1) slice: mulberry branch is cut into the straight section that length is 18mm;

[0050] (2) Steaming before washing: the above-mentioned straight slices are sent into the steaming chamber, and a sodium hydroxide solution (concentration of 50g / l) of 3% of the straight slice weight (net weight) is added in the steaming chamber. The steaming time is 40 minutes at a temperature of 40°C;

[0051] (3) Washing: Wash the steamed straight slices in water at 40°C;

[0052] (4) Steaming after washing: Send the straight slices after washing into the steaming chamber, and steam for about 30 minutes under the condition that the steaming exhaust temperature is 35°C;

[0053] (5) One-stage pressing: the steamed straight slices are sent into the first stage of the screw extruder to be crushed and torn under a pressure of 1.9 kg to form compressed m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com