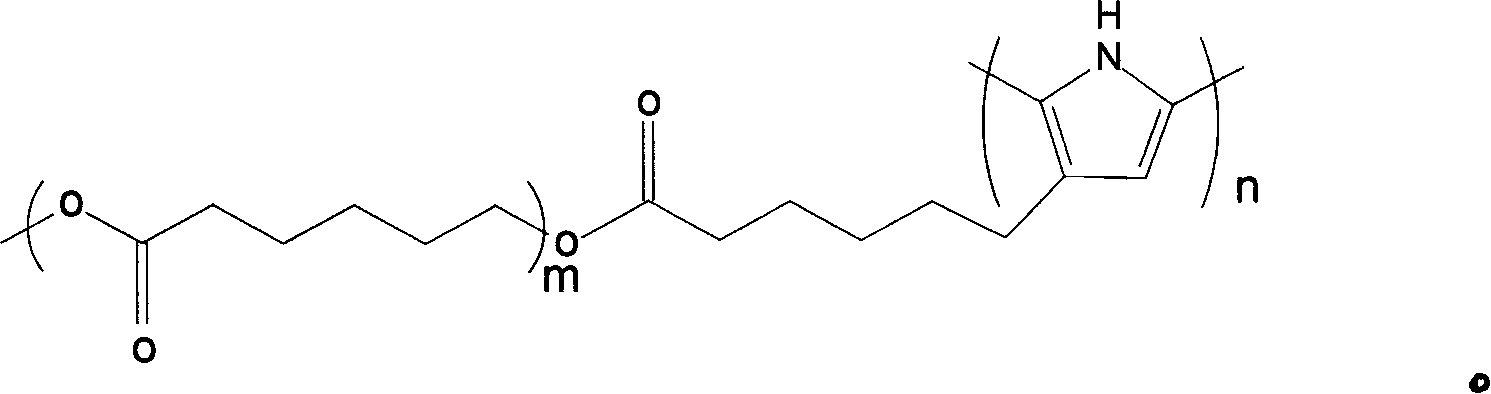

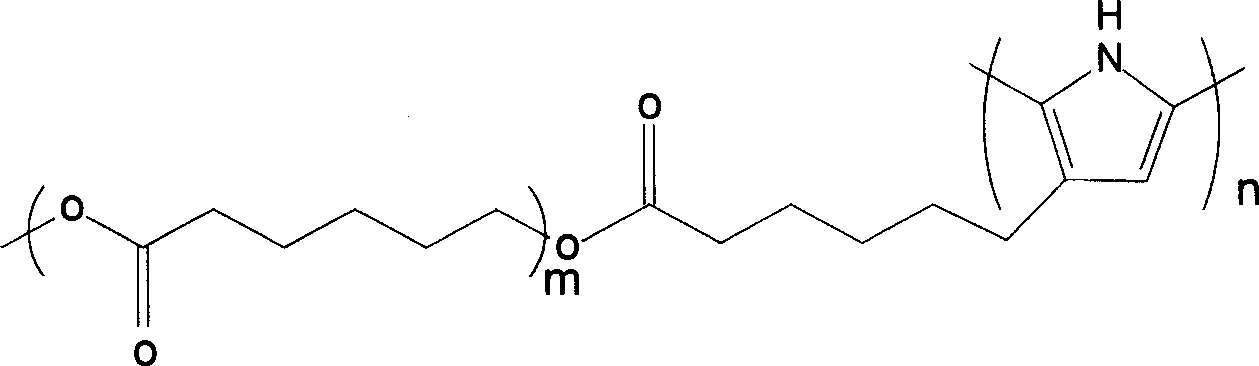

Pyrrole and epsilon-caprolactone copolymer and synthesis process thereof

A synthesis method and caprolactone technology, applied in the field of electrochemistry, can solve problems such as less reports, and achieve the effects of improving mechanical properties, improving thermal stability, and enhancing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] 1. Raw materials:

[0021] Pyrrole, ε-caprolactone, Nitromethane, Tetrabutylammonium boron tetrafluoride. Pyrrole was distilled under reduced pressure and stored in a 0°C refrigerator for later use.

[0022] 2. Electrolyte preparation:

[0023] Add pyrrole and ε-caprolactone into the nitromethane solution, add boron tetrafluoride tetrabutylammonium as supporting electrolyte, and mix the solution evenly. And make the pyrrole concentration 0.1~0.4moldm -3 , the concentration of caprolactone is 0.1~2.0moldm -3 , the concentration of tetrabutylammonium boron tetrafluoride is 0.05~0.1moldm -3 .

[0024] 3. Electrolytic cell preparation:

[0025] The electrolytic cell adopts a three-electrode system, the working electrode is conductive glass, and the counter electrode is platinum wire electrode. Ag / AgCl (saturated KCl) was the reference electrode. The conductive glass is rinsed with distilled water and acetone solution respectively before use. Platinum wire electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com