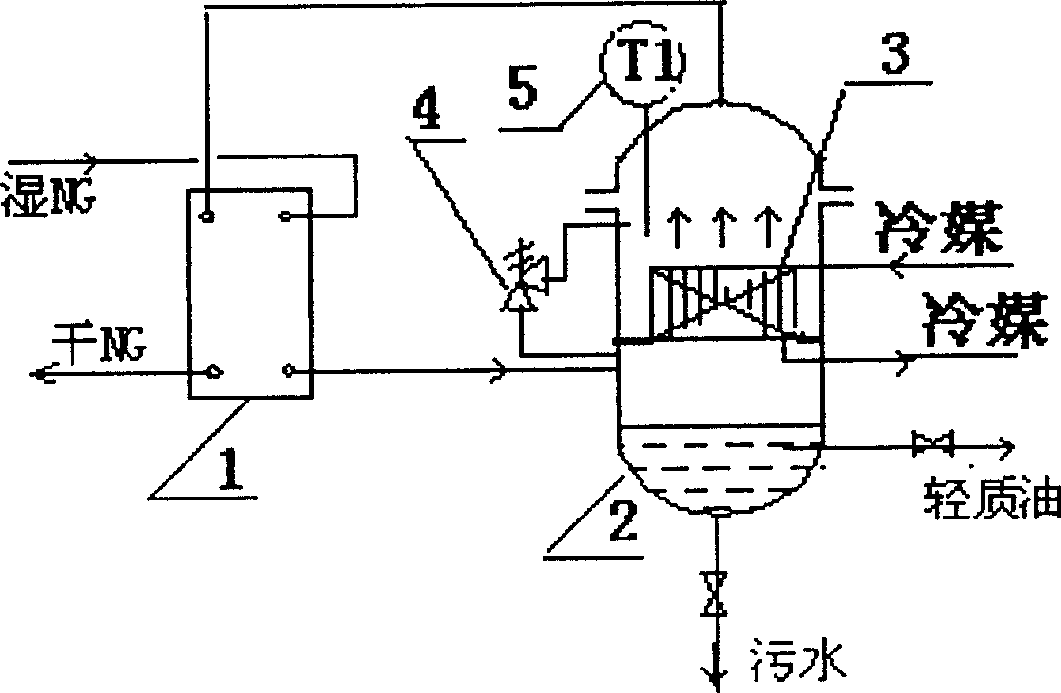

Process for lyophilization and heavy hydrocarbon removal of petroleum natural gas

A technology for oil and natural gas, freezing and dehydration, applied in the petroleum industry, gas fuel, liquid hydrocarbon mixture recovery, etc., can solve the problems of high material consumption cost, incomplete dehydration, complicated operation, etc., achieve good purification effect, solve the problem of freezing, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] Embodiment: According to the above-mentioned technical scheme and implementation steps provided by the present invention, dehydration and deheavy hydrocarbon purification treatment of petroleum gas was carried out at an oil and gas gathering and transportation station in Liaohe Oilfield, China. During this process, the main working parameters are as follows: the wet petroleum gas exchanges heat with the cold and dry gas in the regenerator, and the raw gas enters the vapor-liquid separator after it drops to 10°C; the flow rate of the raw gas passing through the evaporator is 1.5m / s; After the raw material gas drops to -5°C, the steam-liquid separator enters the regenerator; the cold and dry gas enters the external gas pipeline network after being reheated to 28°C; the average temperature of the condensate is 3°C. During this implementation process, the amount of treated petroleum gas is 6000-15000Nm 3 / d, the dew point temperature of the treated natural gas reaches -25℃...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com