Microstructured optical fiber with long wave cut-off function and preparation thereof

A micro-structured optical fiber and long-wave technology, applied in cladding optical fiber, optical waveguide, glass manufacturing equipment, etc., can solve the problems affecting the depth and width of the concave layer of the outer refractive index of the fiber core, affecting the performance of the optical fiber, and the difficulty of making the optical fiber. It is easy to control the refractive index, meet the requirements of practical applications, and have the effect of flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the long-wave cut-off microstructured optical fiber comprises the following two steps:

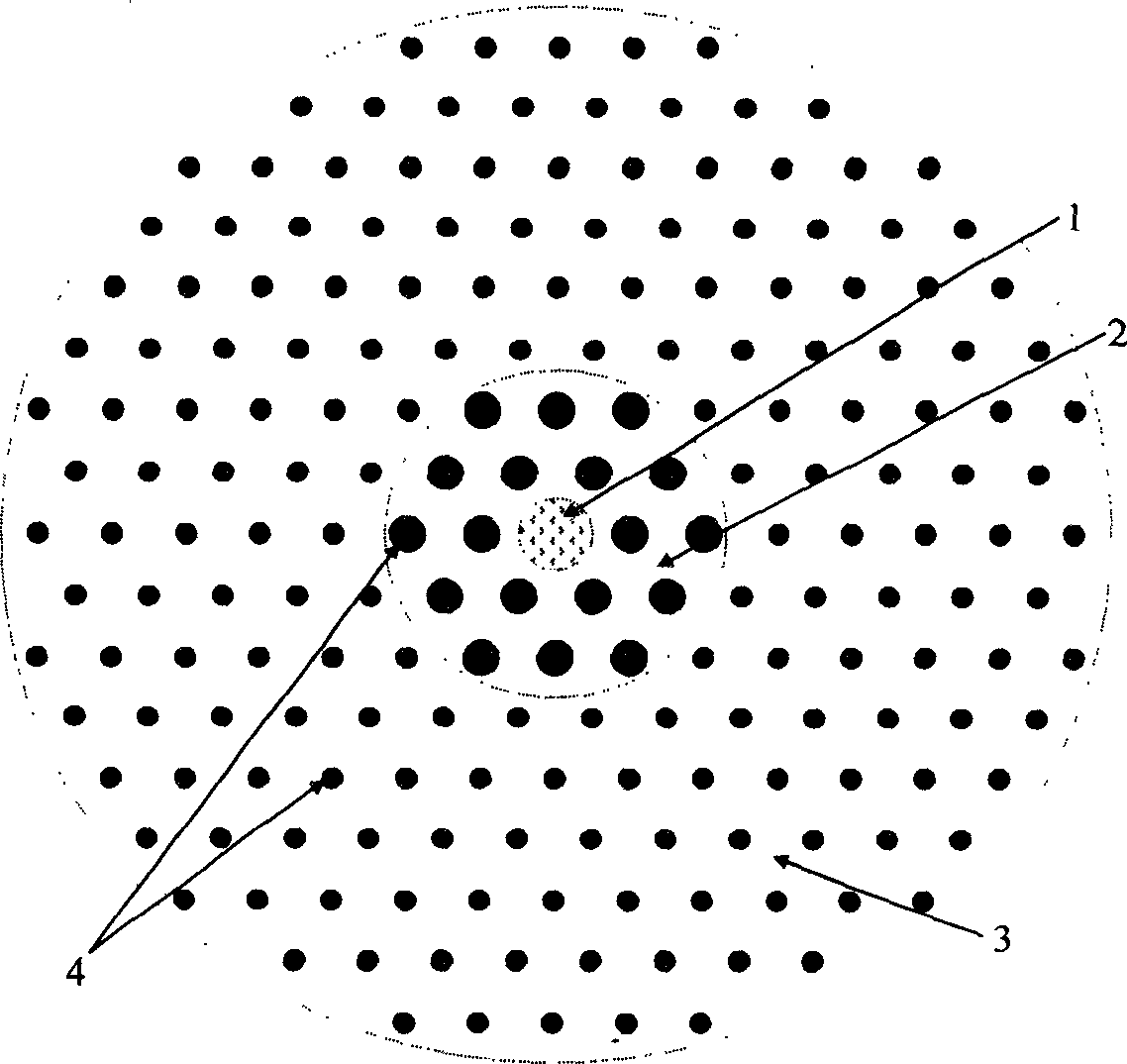

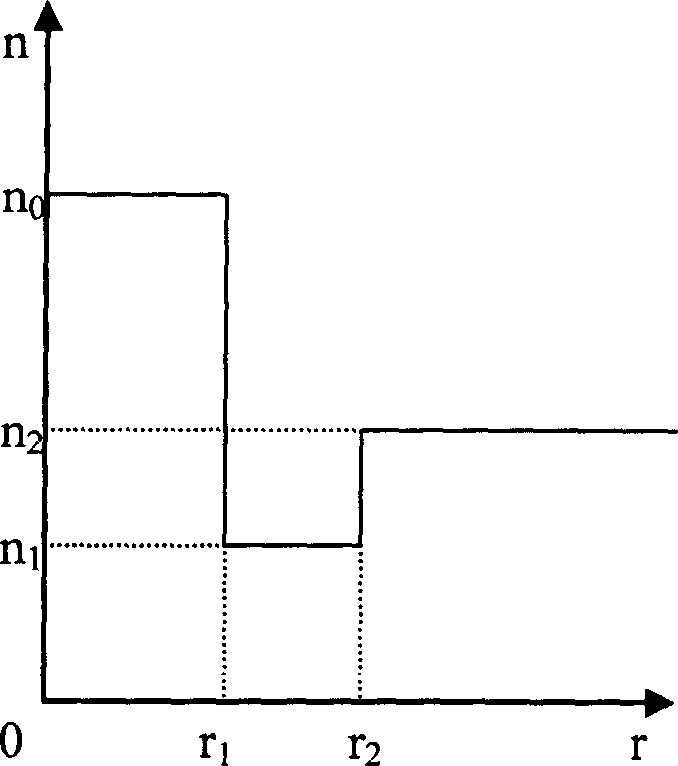

[0023] (1) Make the preform according to the design structure

[0024] Choose a high-purity quartz tube with a suitable diameter and wall thickness, and arrange a certain number of capillaries regularly in it. The size of the capillary is drawn according to the design requirements in advance, and a doped or non-doped solid quartz rod is used as the core in the center.

[0025] In this fabrication process, capillaries of at least two sizes need to be prepared, which are used to construct the refractive index depression layer and the cladding layer respectively.

[0026] (2) Wire drawing of the preform.

[0027] Using an ordinary commercial drawing tower, the preform is melted and drawn into an optical fiber at a high temperature of about 1800 ° C, and a UV-cured protective coating is coated on-line. The corresponding temperature of the melting rod is adopt...

Embodiment

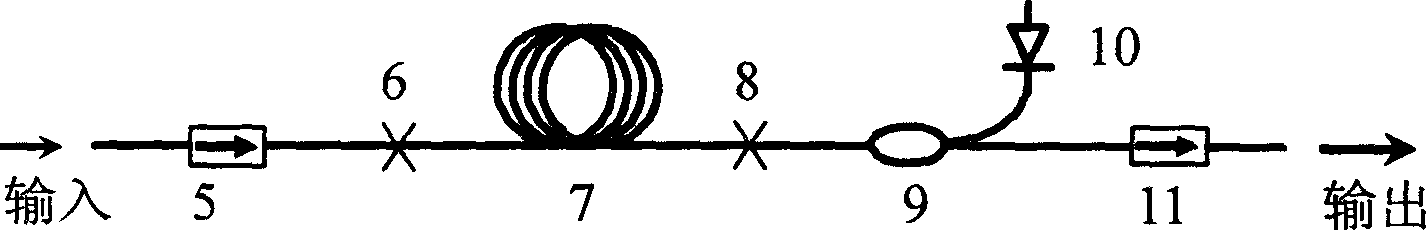

[0036] image 3 It is an embodiment, a structural schematic diagram of constructing an S-band optical fiber amplifier with a long-wave cut-off microstructured optical fiber. The isolator 5, the erbium-doped long-wave cut-off microstructured fiber 7, the wavelength division multiplexing coupler 9, the semiconductor laser 10 and the isolator 11 form an S-band fiber amplifier. The semiconductor laser 10 pumps the erbium-doped long-wave cut-off microstructured fiber 7 through the wavelength division multiplexing coupler 9 to pump the erbium ions in the fiber core to a higher energy level, thereby amplifying the input signal. However, the presence of the recessed refractive index layer in the long-wave cut-off microstructured fiber makes the radiation modes of the C-band and L-band leak out and cannot be amplified, but the radiation of the S-band will be gradually amplified. When in use, the S-band signal is input from the input terminal, and after passing through the isolator 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com