Control released permeation bump tablet of venlafaxine hydrochloride and its prepn process

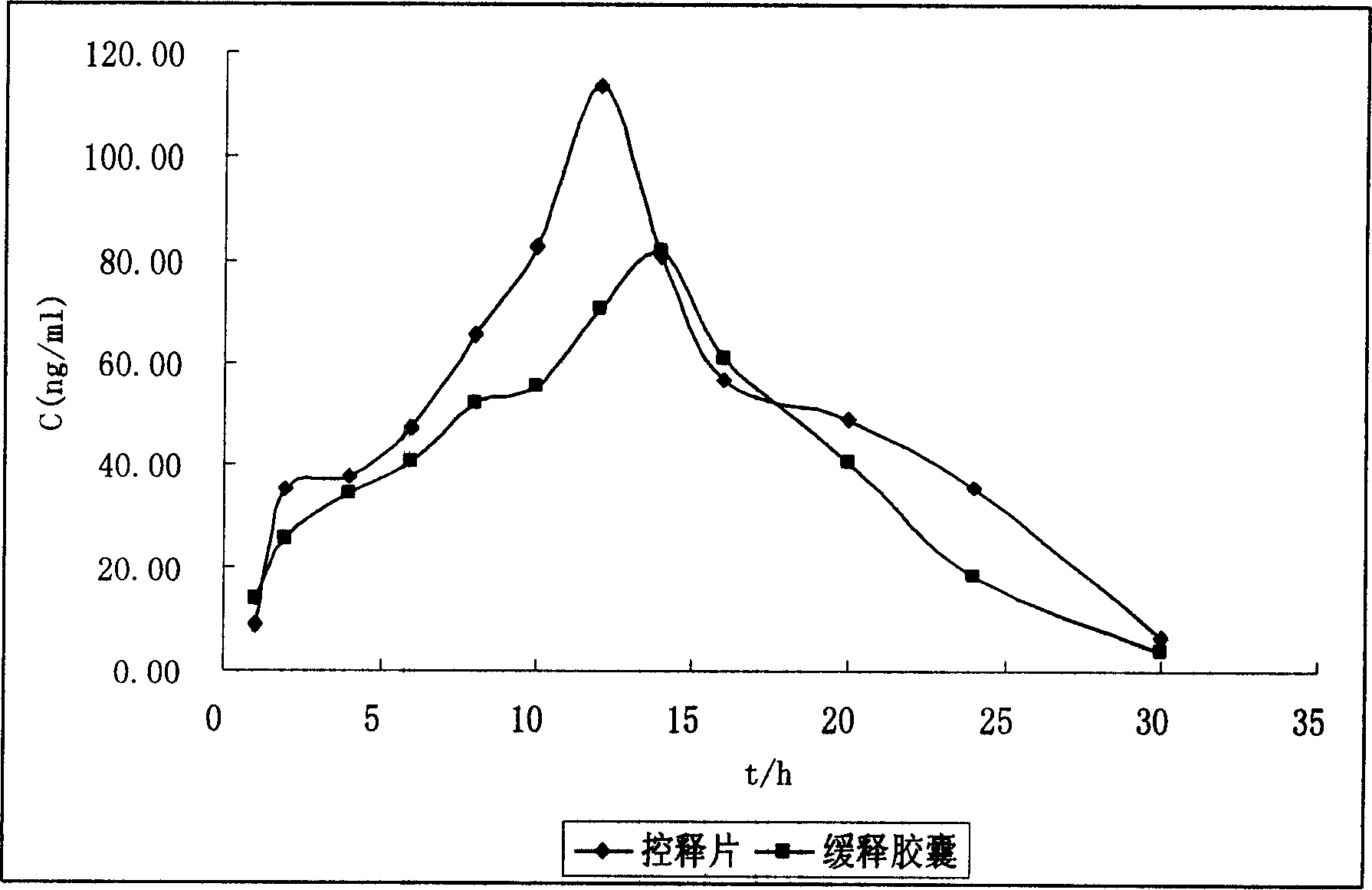

A technology of venlafaxine hydrochloride and osmotic pump controlled release, applied in pharmaceutical formulations, medical preparations containing active ingredients, drug delivery, etc. problems, to achieve the effect of small fluctuation, small gastrointestinal side effects, and stable blood drug concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

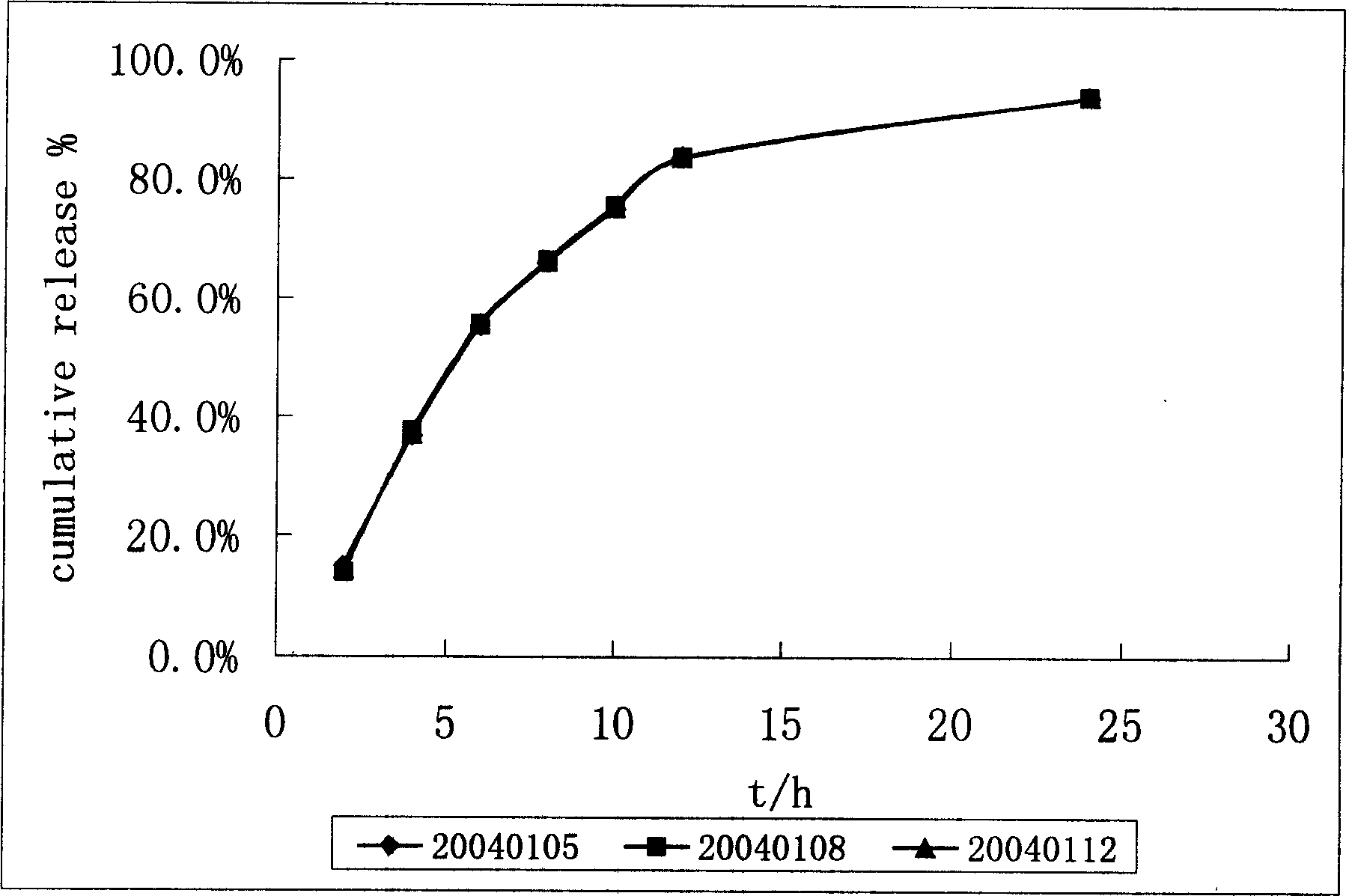

Method used

Image

Examples

Embodiment 1

[0026] The venlafaxine hydrochloride osmotic pump controlled-release tablet preparation with a weight ratio of drug tablet core and semipermeable film coating of 1:0.035, wherein:

[0027] The composition of the drug tablet core is: 75 parts of venlafaxine hydrochloride, 114 parts of microcrystalline cellulose, 4 parts of sodium chloride, 6 parts of povidone K30 and 1 part of magnesium stearate.

[0028] The composition of the semipermeable film coating was: 9 parts of cellulose acetate, 0.78 parts of diethyl phthalate and 0.22 parts of polyethylene glycol 1500.

[0029] The preparation method of the above-mentioned venlafaxine hydrochloride osmotic pump controlled-release tablet preparation comprises the following steps:

[0030] (1) Preparation of drug tablet core: get the venlafaxine hydrochloride, microcrystalline cellulose, sodium chloride and povidone K30 of the proportioning, mix well, add 95% ethanol solution to make soft material in right amount, pass 20 Mesh sieve g...

Embodiment 2

[0035] The venlafaxine hydrochloride osmotic pump controlled-release tablet preparation in which the weight ratio of the drug tablet core and the semipermeable film coating is 1:0.05, wherein:

[0036] The composition of the drug tablet core is: 75 parts of venlafaxine hydrochloride, 120 parts of microcrystalline cellulose, 1 part of sodium chloride, 15 parts of povidone K30 and 0.1 part of magnesium stearate.

[0037] The composition of the semipermeable film coating was: 6 parts of cellulose acetate, 0.9 part of diethyl phthalate and 0.1 part of polyethylene glycol 1500.

[0038] The preparation method of the above-mentioned venlafaxine hydrochloride osmotic pump controlled-release tablet preparation comprises the following steps:

[0039] (1) Preparation of drug tablet core: get the venlafaxine hydrochloride, microcrystalline cellulose, sodium chloride and povidone K30 of the proportioning, mix well, add 90% ethanol solution to make soft material in right amount, pass 20 M...

Embodiment 3

[0044] The venlafaxine hydrochloride osmotic pump controlled-release tablet preparation in which the weight ratio of the drug tablet core and the semipermeable film coating is 1:0.02, wherein:

[0045] The composition of the drug tablet core is: 75 parts of venlafaxine hydrochloride, 100 parts of microcrystalline cellulose, 30 parts of sodium chloride, 1 part of povidone K30 and 10 parts of magnesium stearate.

[0046] The composition of the semipermeable film coating was: 12 parts of cellulose acetate, 0.6 part of diethyl phthalate and 0.4 part of polyethylene glycol 1500.

[0047] The preparation method of the above-mentioned venlafaxine hydrochloride osmotic pump controlled-release tablet preparation comprises the following steps:

[0048] (1) Preparation of drug tablet core: get the venlafaxine hydrochloride, microcrystalline cellulose, sodium chloride and povidone K30 of the proportioning, mix well, add 95% ethanol solution to make soft material in right amount, pass 20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com