Parallel Fs laser double photon photopolymerization micro-nano processing method and apparatus thereof

A femtosecond laser and micro-nano processing technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of uneven light distribution, energy loss, light intensity difference, etc., and achieve high processing resolution and consistent processing resolution and the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

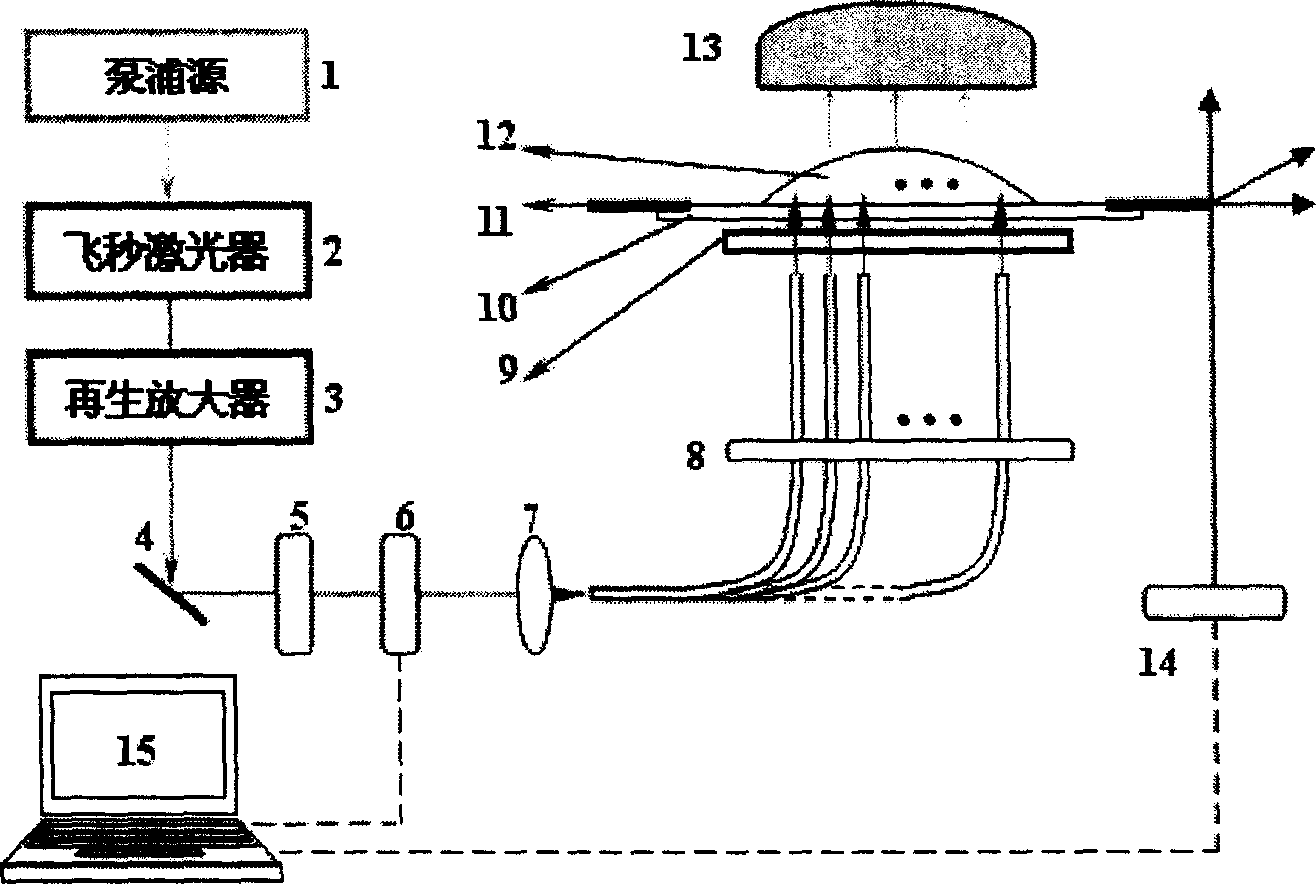

[0019] combine figure 1 The device schematic diagram of the parallel femtosecond laser two-photon photopolymerization micro-nano processing of the example is described as follows for the details and implementation of the specific device of the present invention:

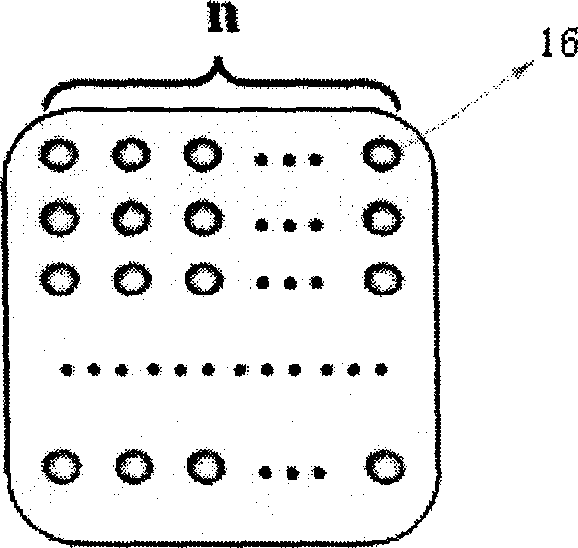

[0020] The device for realizing parallel femtosecond laser two-photon photopolymerization micro-nano processing is mainly composed of a laser generation system, an external optical path system and a processing control system. The laser generating system includes a pump light source 1 , a femtosecond laser 2 and a regenerative amplifier 3 . The external optical path system includes a dimming system and a beam focusing system, and the main components include a total reflection mirror 4, an attenuation mirror 5, an optical shutter 6, a fiber coupler 7, an optical fiber array 8, and a microlens array 9, etc. The processing control system includes two parts, namely the micro-nano processing system and the software contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com