Thermolysis of organic waste in a ball furnace

A technology for organic waste and waste, applied in incinerators, coke ovens, special forms of dry distillation, etc., can solve problems such as unreachable temperature, impossible waste, and providing satisfactory solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

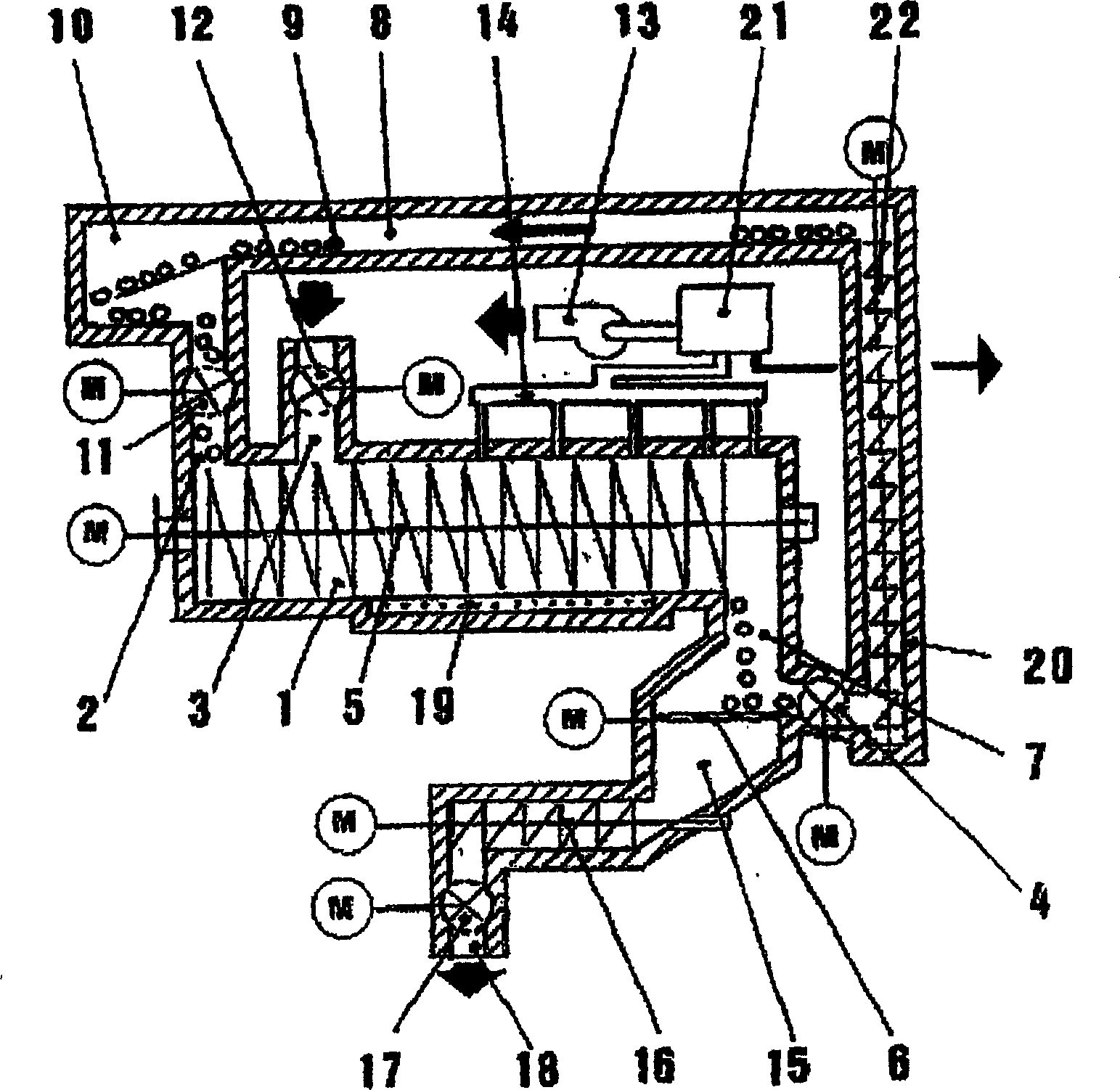

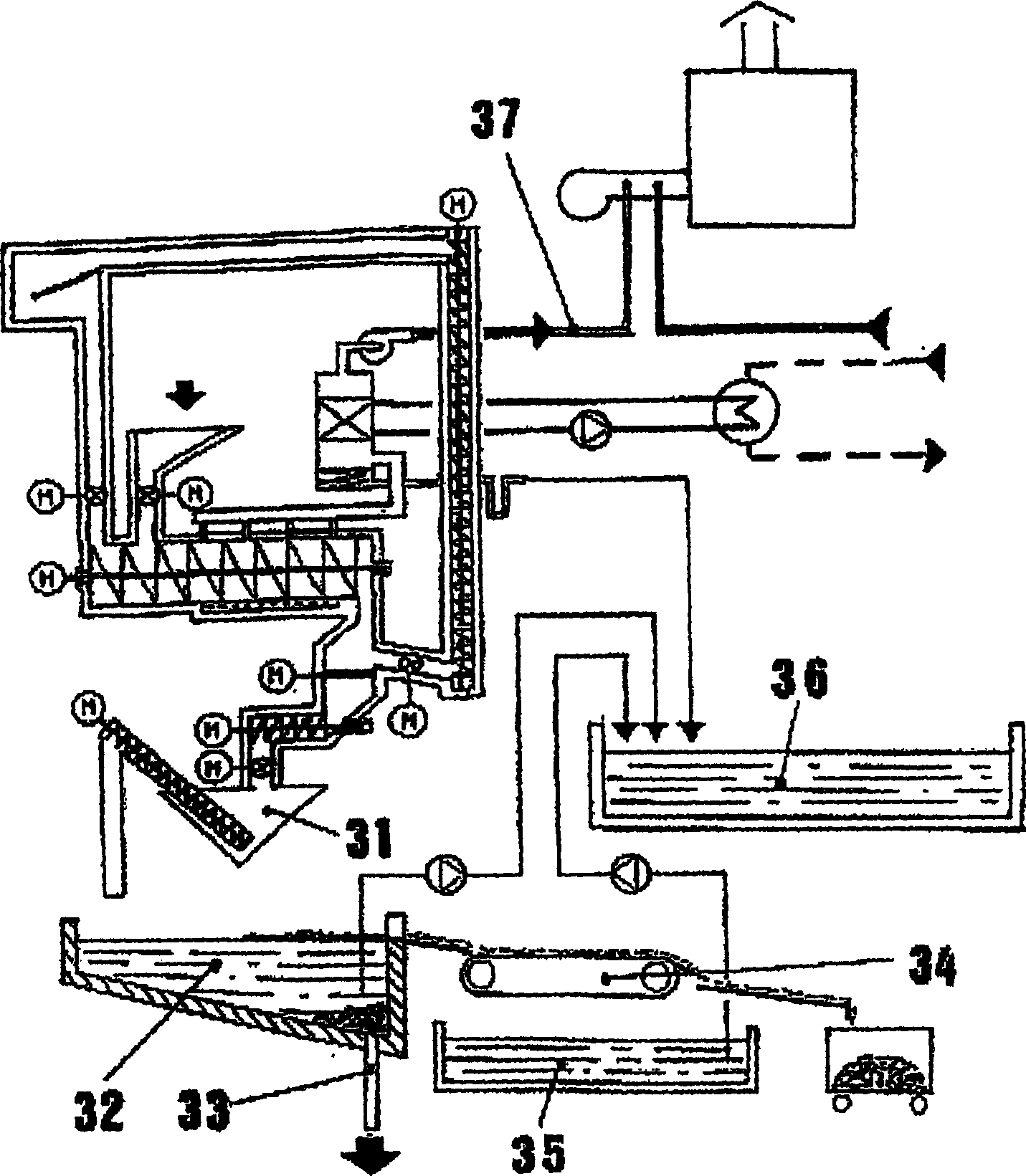

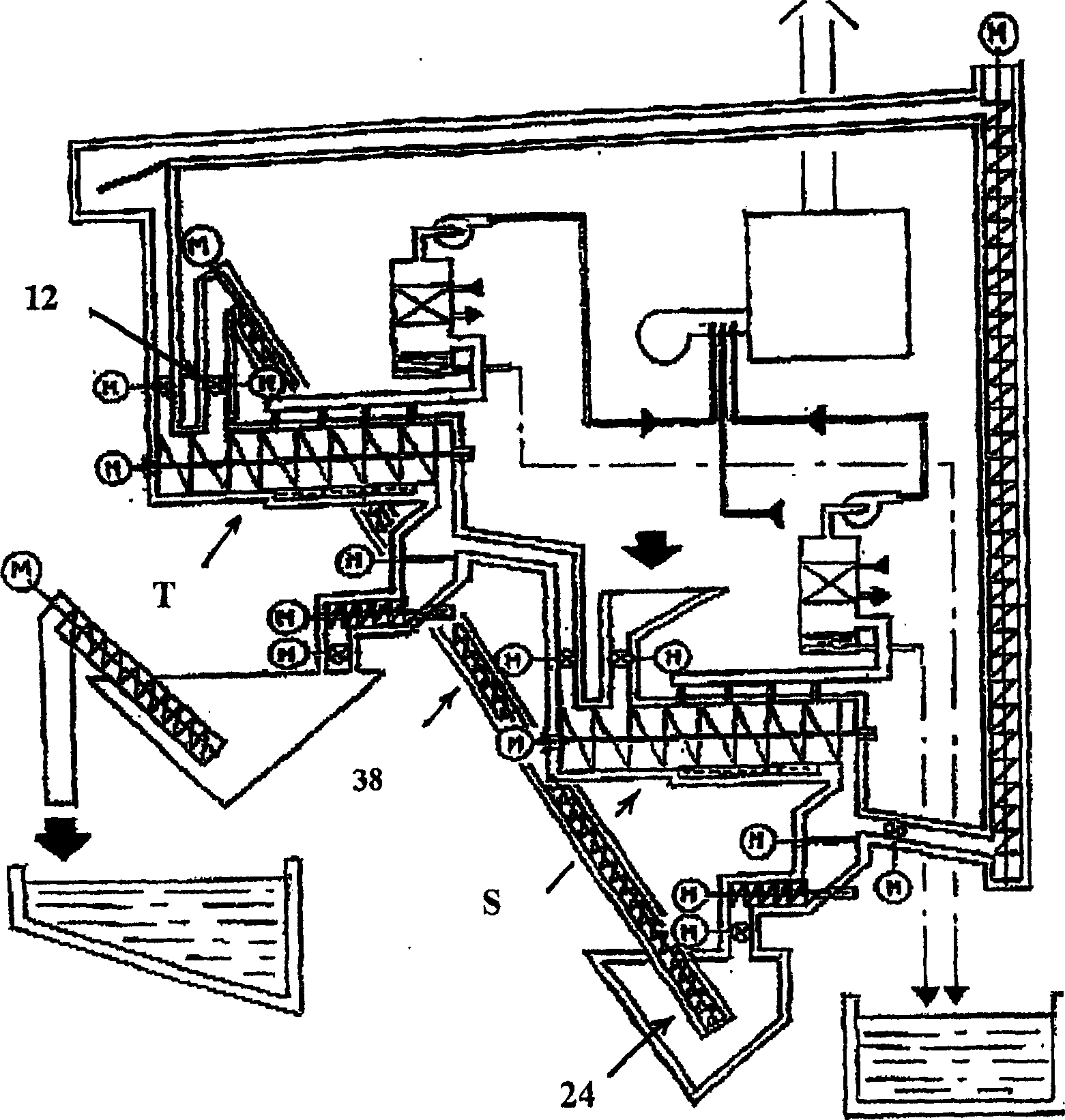

[0086] A continuous pyrolysis plant is arranged around a tubular reactor with a diameter of 0.7 m and a total length of 7.2 m, which treats 800 tons (i.e. about 100 kg / hour) of pre-dried waste per year to reduce the water content to 5%, It was determined to contain 70% organic matter (average composition).

[0087] For 100 kg of waste, the energy required for pyrolysis was determined by preliminary experiments to be 50 kWh (excluding heat loss). The average pyrolysis temperature was set at 600 °C.

[0088] The heating substance consisted of 20 mm diameter steel balls, the total amount of which was estimated as follows.

[0089] When using the average specific heat of steel equal to 0.174W / kg / ℃, the amount of heating material whose heat is dropped from 700℃ to 500℃ is 50000 / (0.174×200)=1437kg, in other words 44000 pieces with a diameter of 20mm balls (32.65g / ball).

[0090]The unit produces about 600 kWh of reusable gas at a rate of about 70 kg / hour, and 25 kg of solid resid...

Embodiment 2

[0092] The same equipment can be used to process slaughter waste. It guarantees pyrolysis throughout the mass at a temperature of 700°C and can reach 900°C if hazardous waste is involved, at which temperature all proteins, including possible prions, are destroyed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com