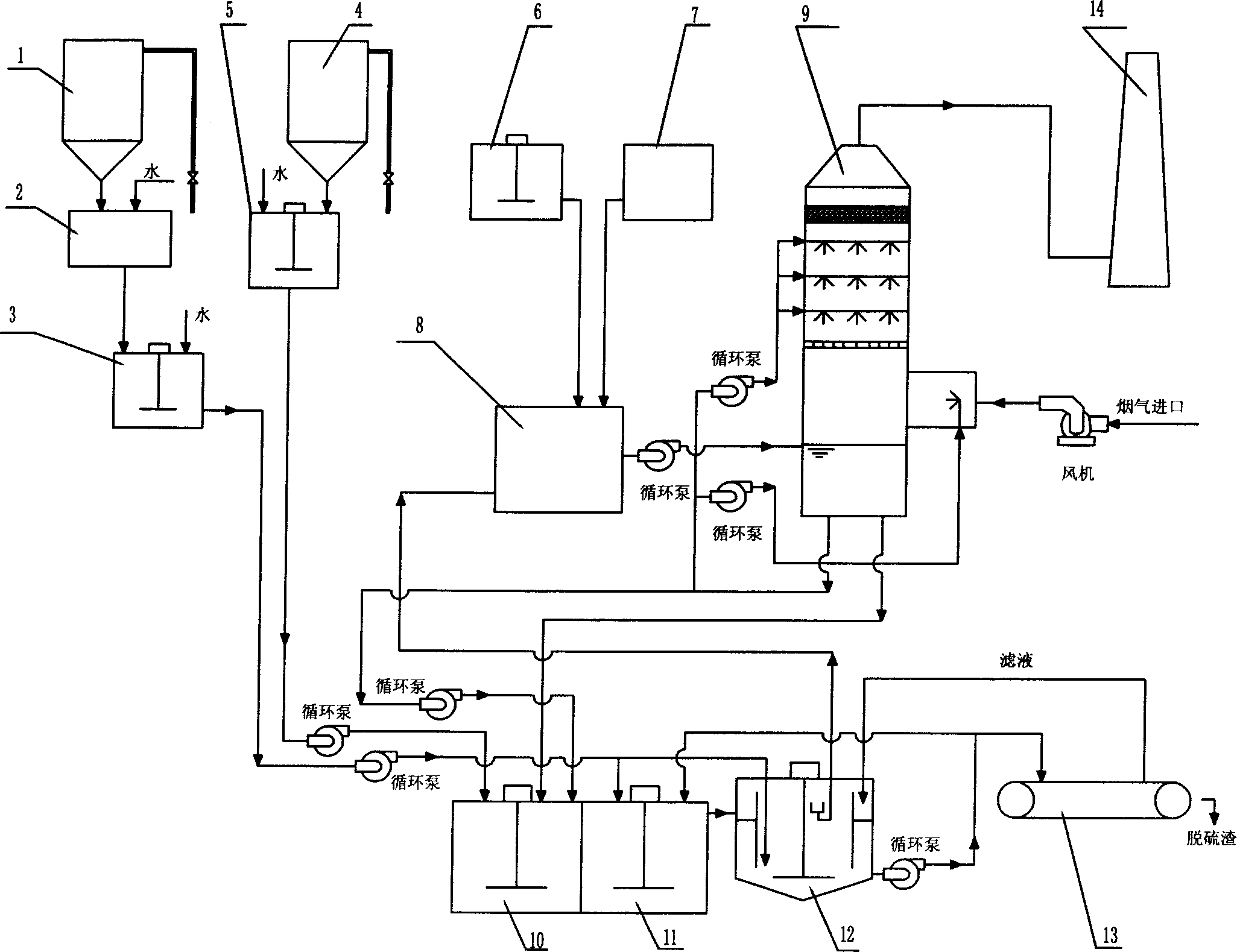

Fume desulfurizing process employing multiple circulation and stable double alkali method and apparatus

A technology of multiple cycles and desulfurization processes, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of easy fouling and blockage of the reaction pool, easy damage to the system balance, and difficult maintenance of tower internals. High liquid separation efficiency, prolonging the regeneration reaction time, and reducing the effect of mist entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] We conducted a 2×240t / h coal-fired boiler flue gas desulfurization engineering experiment in a power plant, and the flue gas volume was 2×270000Nm 3 / h, the concentration of sulfur dioxide in the flue gas is 1600mg / Nm 3 , the sulfur dioxide absorption efficiency is 96%, and the cost of desulfurization is 0.6 cents per kilowatt-hour of electricity. Main equipment: DN6000×23000mm two absorption towers, mixer 200m 3 , primary regeneration reactor 120m 3 , secondary regeneration reactor 120m 3 , high efficiency clarifier 800m 3 , 10m 2 One vacuum belt dehydrator.

[0057] (1) Internal circulation of desulfurization absorption liquid

[0058] Set up two absorption towers of DN6000×23000mm, the flue gas from the induced draft fan of the boiler passes through the inlet side quenching spray layer, the bottom grille turbulence layer in the tower, the spray layer, and the top folding plate defogging layer after desulfurization and defogging are completed. Chimney, the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com