Process for electric spark deposition preparation of titanium nitride-base ceramic coating

A technology of electric spark deposition and ceramic coating, applied in metal material coating process, coating, solid-state diffusion coating, etc. Widen the scope of application, low cost, strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

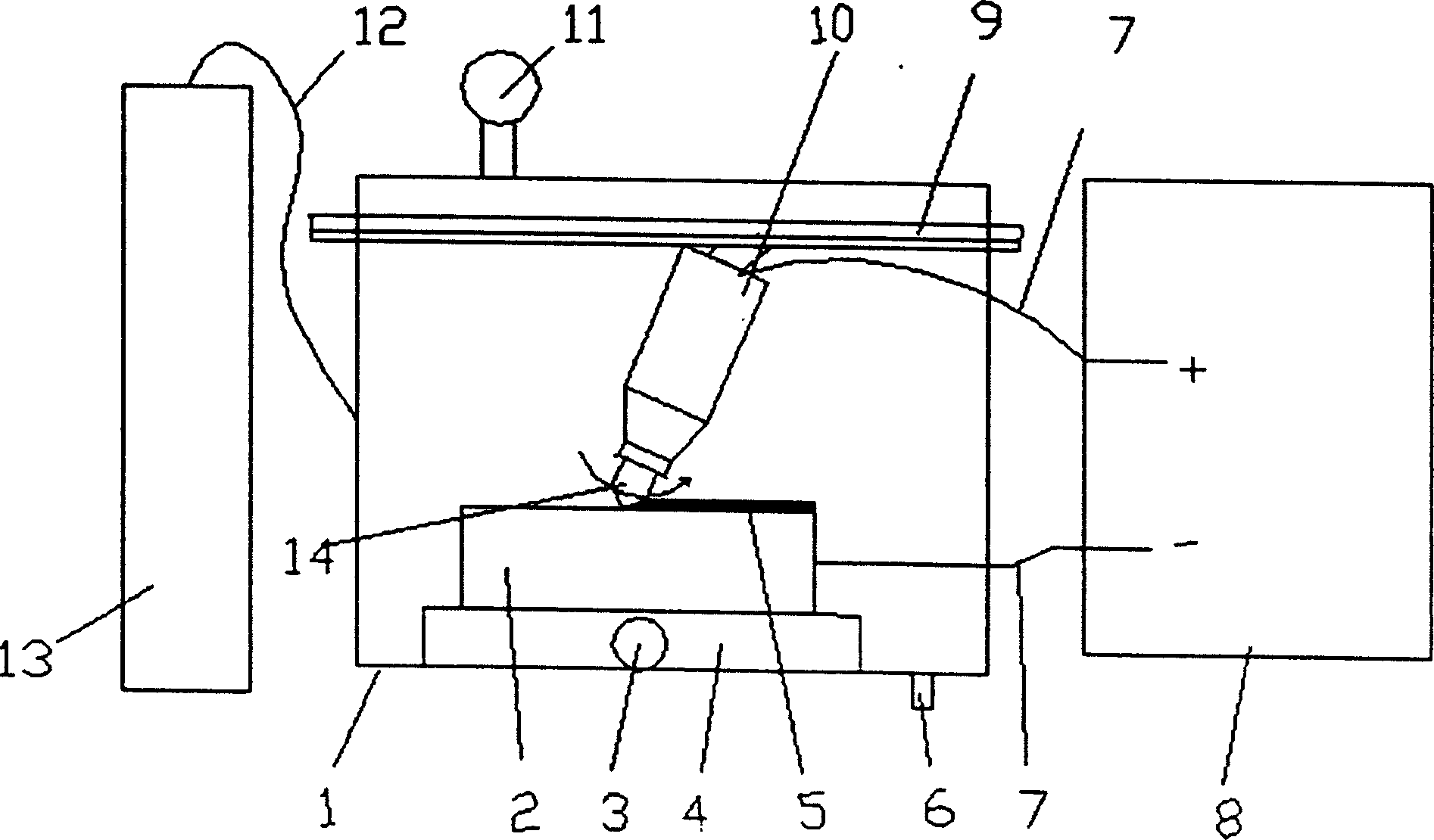

[0018] A method for preparing a titanium nitride metal-based ceramic coating by reactive spark deposition, the content of which is to use titanium and its alloys as electrodes, and use the spark deposition technology in a nitrogen protective atmosphere to synthesize surface-treated coatings through in-situ reactions. A titanium nitride metal-based ceramic coating is formed on the surface of the metal substrate.

[0019] A nitrogen-enclosed device is used as a working chamber.

[0020] The electrode used is a rotating electrode with a rotation speed of 2400r / min.

[0021] The diameter of the electrode used is 3 mm.

[0022] The nitrogen purity used is 99.99%, and the supply rate is 10L / min.

[0023] The metal matrix used is 20# steel specimen.

specific Embodiment approach

[0024] The present invention adopts above-mentioned invention method, on the surface of 20# steel test piece, with the industrial TA of φ 3mm 2 Titanium wire was used as the electrode, and the titanium nitride metal-based ceramic coating was prepared by reactive electric spark deposition using high-purity nitrogen with a purity of 99.99% as the protective gas. The specific implementation is as follows:

[0025] Before the deposition operation, the test piece 2 is clamped on the workbench 4 in the nitrogen-enclosed device 1 , and the nitrogen in the gas source 13 is introduced into the nitrogen-enclosed device 1 through the gas pipe 12 . The air pressure in the nitrogen-enclosed device 1 is adjusted through the safety valve 6 , and the pressure gauge 11 is used to display the pressure in the nitrogen-enclosed device 1 .

[0026] During the deposition operation, the electric spark deposition power supply 8 is turned on, the electrode 14 on the deposition gun 10 is electrified a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com