Composition of medicine for treating diarrhea

A drug and diarrhea technology, applied in the field of medicine, can solve the problems of low natural degree, low natural degree, and low pure natural degree of dripping pill excipients, so as to reduce the irritating smell of drugs, improve the pH of the mouth, and have a high natural degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

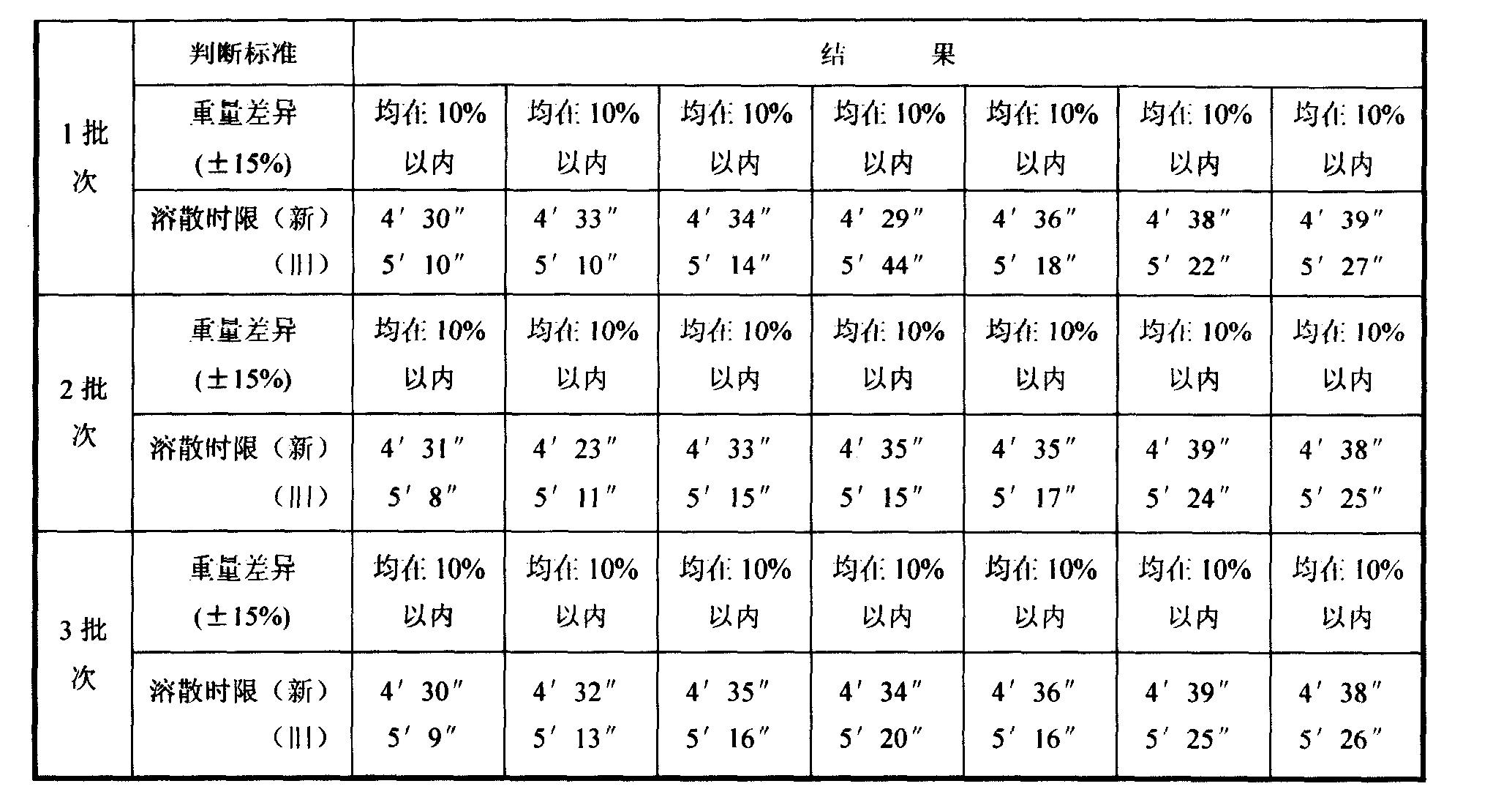

Image

Examples

Embodiment 1

[0054] (a): take Coptidis Rhizoma, Magnolia officinalis, Woody Fragrance, and dried ginger for later use;

[0055] (b): Extract effective active substances from Coptis Rhizoma, Magnolia Officinalis, Woody Fragrance, and Dried Ginger after crushing, wherein Coptidis Rhizome uses ethanol as a solvent, reflux extracts, refines with hydrochloric acid after drying, and obtains Coptis Rhizoma extract; Magnolia officinalis , woody incense, and dried ginger are extracted with supercritical carbon dioxide fluid extraction equipment to extract effective active substances, wherein the extraction pressure of Magnolia Bark Extract is 21-25MPa, the extraction temperature is 35-40°C, and the extraction time is 3-5 hours to obtain Magnolia Bark Extract The extraction pressure of woody oil is 24~28MPa, the extraction temperature is 35~40°C, the extraction time is 3~5 hours, and the extraction pressure of dried ginger oil is 25~29MPa, the extraction temperature is 38~42°C, and the extraction tim...

Embodiment 2

[0057] (a): Take 5 g of Coptidis Rhizoma extract obtained according to the method of Example 1, 5 g of Magnolia officinalis extract, 1 g of woody oil, 1 g of dried ginger oil, 17.3 g of lactitol, and 5.2 g of starch for subsequent use;

[0058] (b): Put lactitol and starch in a container, mix well, heat and melt the mixture at 60-85°C, add fine powder of Coptis chinensis extract and stir evenly to dissolve completely, then add Magnolia officinalis extract, Wood fragrance oil, dried ginger oil, stir evenly, stirring time is 10-30 minutes, keep warm, drip at 60-85°C, drop into the methyl silicone oil with a diameter of 1.1-3.5 mm, drop into 0-18°C , drain the formed dripping pills and wipe off the cooling liquid, pack them after drying, and make 1000 dripping pills.

Embodiment 3

[0060] (a): Take 9.3g of Coptis Rhizoma extract obtained according to the method of Example 1, 9.3g of Magnolia officinalis extract, 4.5g of woody oil, 4.5g of dried ginger oil, 48.75g of xylitol, and 13.25g of gum arabic for subsequent use;

[0061](b): Mix xylitol and gum arabic in a container, heat and melt the mixture at 60-85°C, add the above-mentioned raw drug powder, mix well, and stir evenly. The stirring time is 10-30 minutes. Dropping at a temperature of ~85 ° C, the diameter of the dropper is 1.2 ~ 2.5 mm, drop into the liquid paraffin at 0 ~ 18 ° C to drain the formed drop pills and wipe off the cooling liquid, and pack them after drying to make 5000 drops Pills, that is.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com