Normal atmosphere plasma burnishing device

An atmospheric pressure plasma and polishing device technology, applied in the field of polishing devices, can solve the problems of difficult surface cleaning, low efficiency, surface and subsurface damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

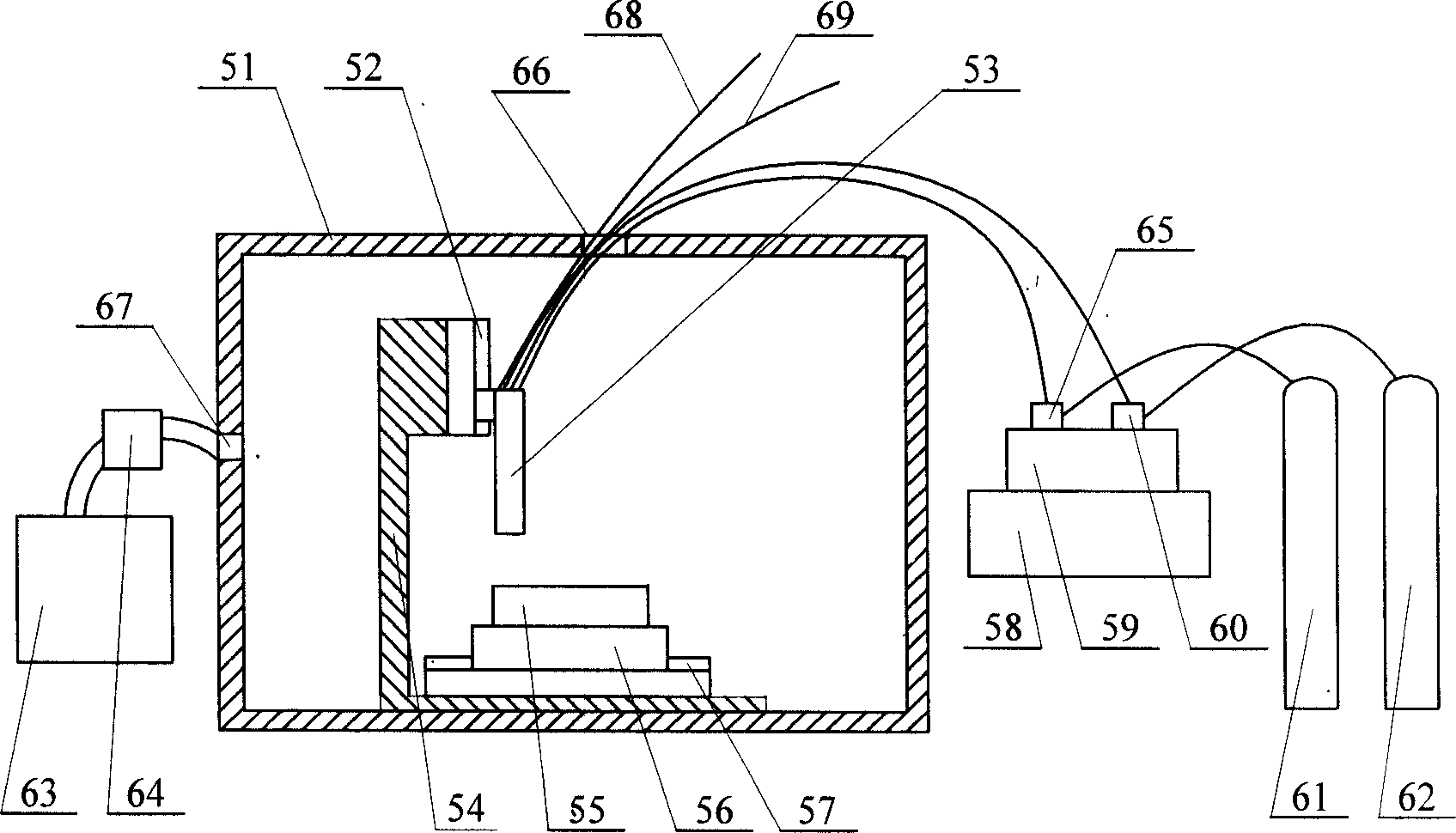

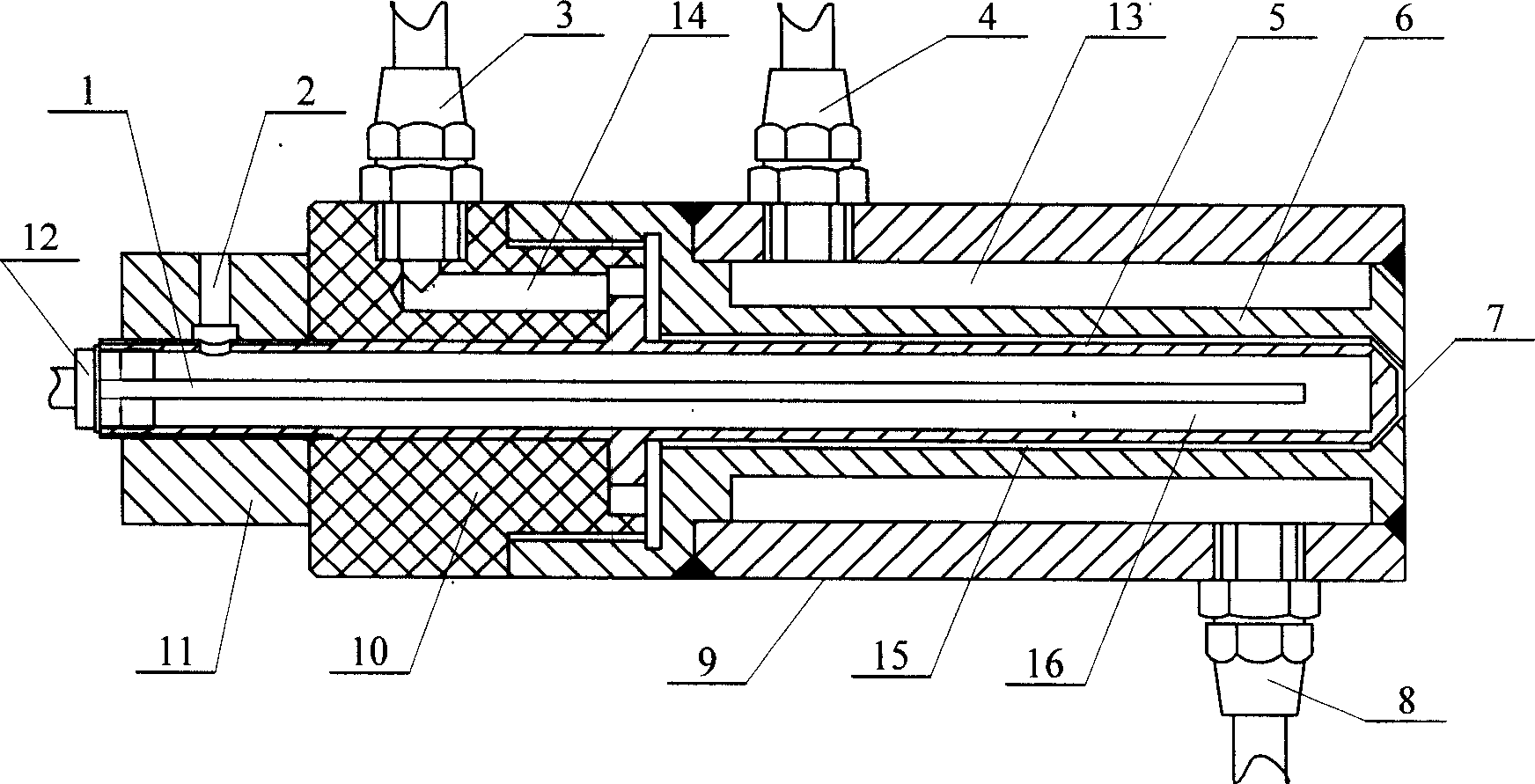

[0013] Specific implementation mode one: (see figure 1 , figure 2 ) This embodiment consists of a closed working cabin 51, a first linkage system 52, a plasma torch 53, a workbench 56, a second linkage system 57, a radio frequency power supply 58, a radio frequency matching device 59, a first flow controller 60, and a reaction gas bottle 61. Composed of plasma gas bottle 62, gas recovery treatment device 63, negative pressure pump 64, second flow controller 65, water inlet pipe 68 and water outlet pipe 69, the first linkage system 52 and the second linkage system 57 are fixed together at the On the common base 54 on the bottom inner wall of the airtight working cabin 51, the plasma torch 53 is installed on the first linkage system 52 and can realize linear motion and rotary motion on the first linkage system 52. The first linkage system 52 mainly functions In order to adjust the distance between the plasma torch 53 and the workpiece 55 and ensure that the axis direction of t...

specific Embodiment approach 2

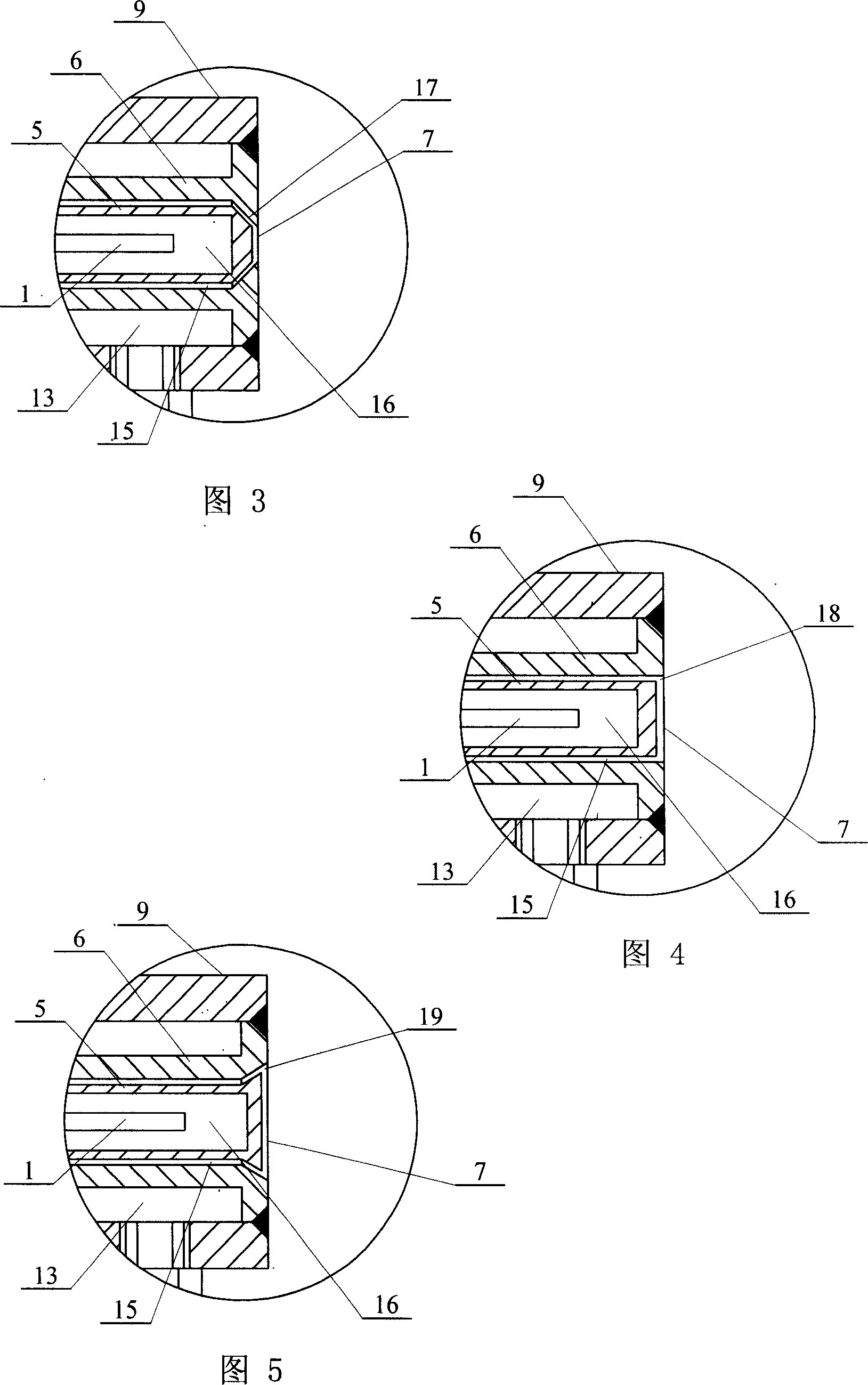

[0015] Specific implementation mode two: (see figure 2 , Fig. 3) The outlet 7 of the cathode 6 of the plasma torch 53 of the present embodiment is a small truncated cone shape 17 with a large inner opening and a small outer opening, and the right end of the anode 5 corresponds to the truncated cone shape 17 of the outlet 7 of the cathode 6. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Specific embodiment three: (referring to Fig. 4) the outlet 7 of the cathode 6 of the plasma torch 53 of the present embodiment is a straight mouth shape 18, and the right end of the anode 5 corresponds to the straight mouth shape 18 of the outlet 7 of the cathode 6. Other compositions and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com