Air purification cooling waste water treatment method for viscose glue fiber workshop

A technology for production workshop and air purification, applied in infiltration/dialysis water/sewage treatment, etc., can solve problems such as distance, achieve the effect of reasonable process route, ensure stable operation, and reduce suspended solids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

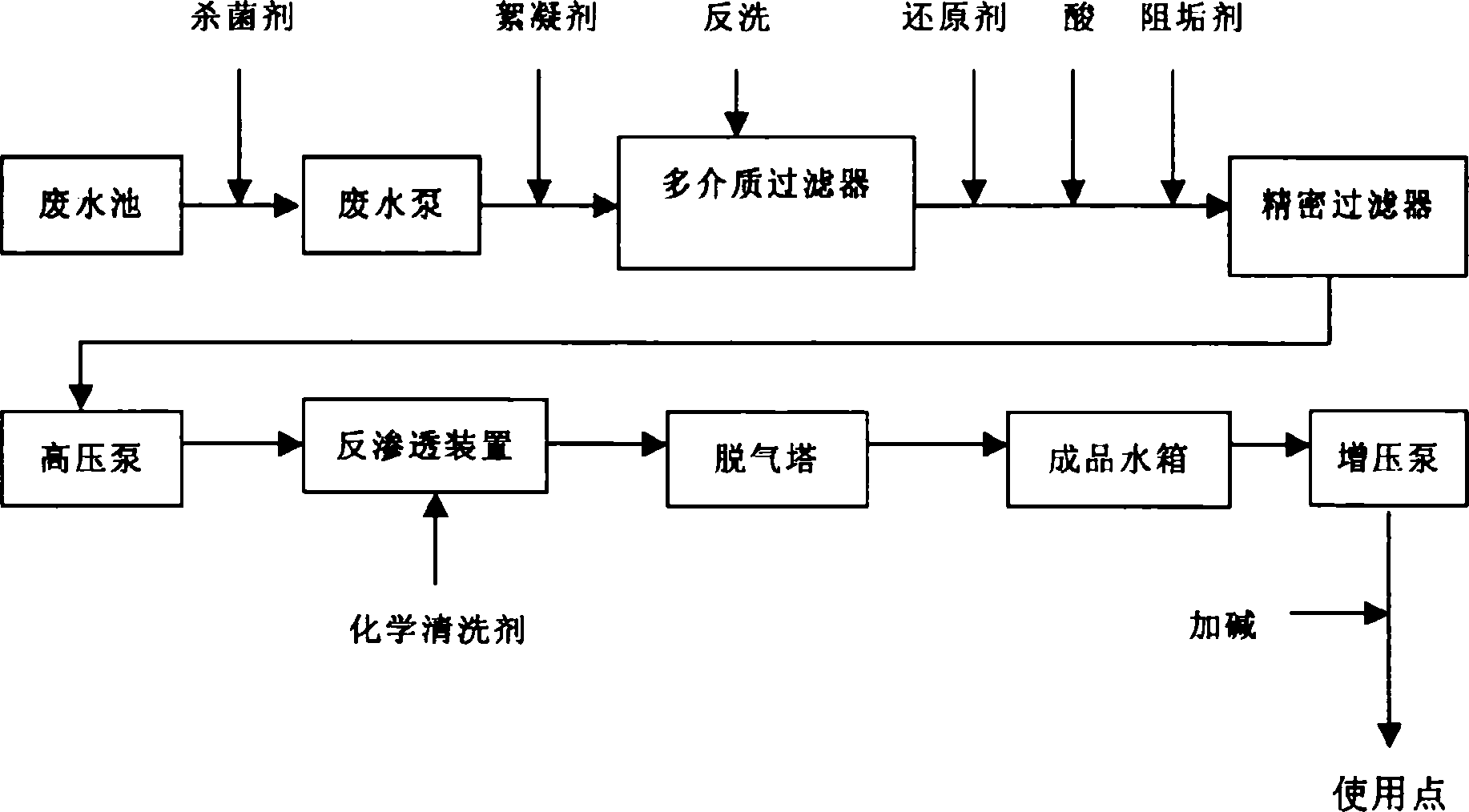

[0043] Example 1: Press figure 1 The process flow chart shown is established, and the daily wastewater treatment capacity is 12,000 tons.

[0044] Its process equipment is:

[0045]

[0046] 1), Wastewater sterilization treatment

[0047] The pretreatment process runs continuously. Add 3 grams of oxidant chlorine dioxide per ton of wastewater, first mix it into water, inject it into the pipeline by means of pump quantitative delivery, and carry out stirring and sterilization. The processing time of the process section is generally 10-30 minute;

[0048] 2), flocculation and filtration treatment

[0049] Add the flocculant ST at an amount of 0.8 grams per ton of wastewater, first mix it into an aqueous solution, and then use a pump to pour it into the pipeline quantitatively. After mixing and flocculating for 5 to 10 minutes, the suspended particles and colloidal substances are flocculated into larger sizes;

[0050] 3), Multi-media filter filtration

[0051] Put the st...

Embodiment 2

[0074] As the method and steps of embodiment 1, the sterilizing agent in process step 1 wherein is sodium hypochlorite. Or constant use of hydrogen peroxide and ozone can also be used instead.

Embodiment 3

[0076] Like the method and steps of Example 1, the flocculant in the process step 2 is MPT100 (produced by Argo Scientific). Alternatively, polyaluminum chloride (PAT) can be used instead.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Total hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com