Dicyclopentadiene modified unsaturated polyester resin preparation method

A technology of dicyclopentadiene and polyester resin, which is applied in the field of preparation of dicyclopentadiene modified unsaturated polyester resin, and can solve problems such as the reduction of mechanical properties of UPR products and the influence of heat resistance of UPR products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

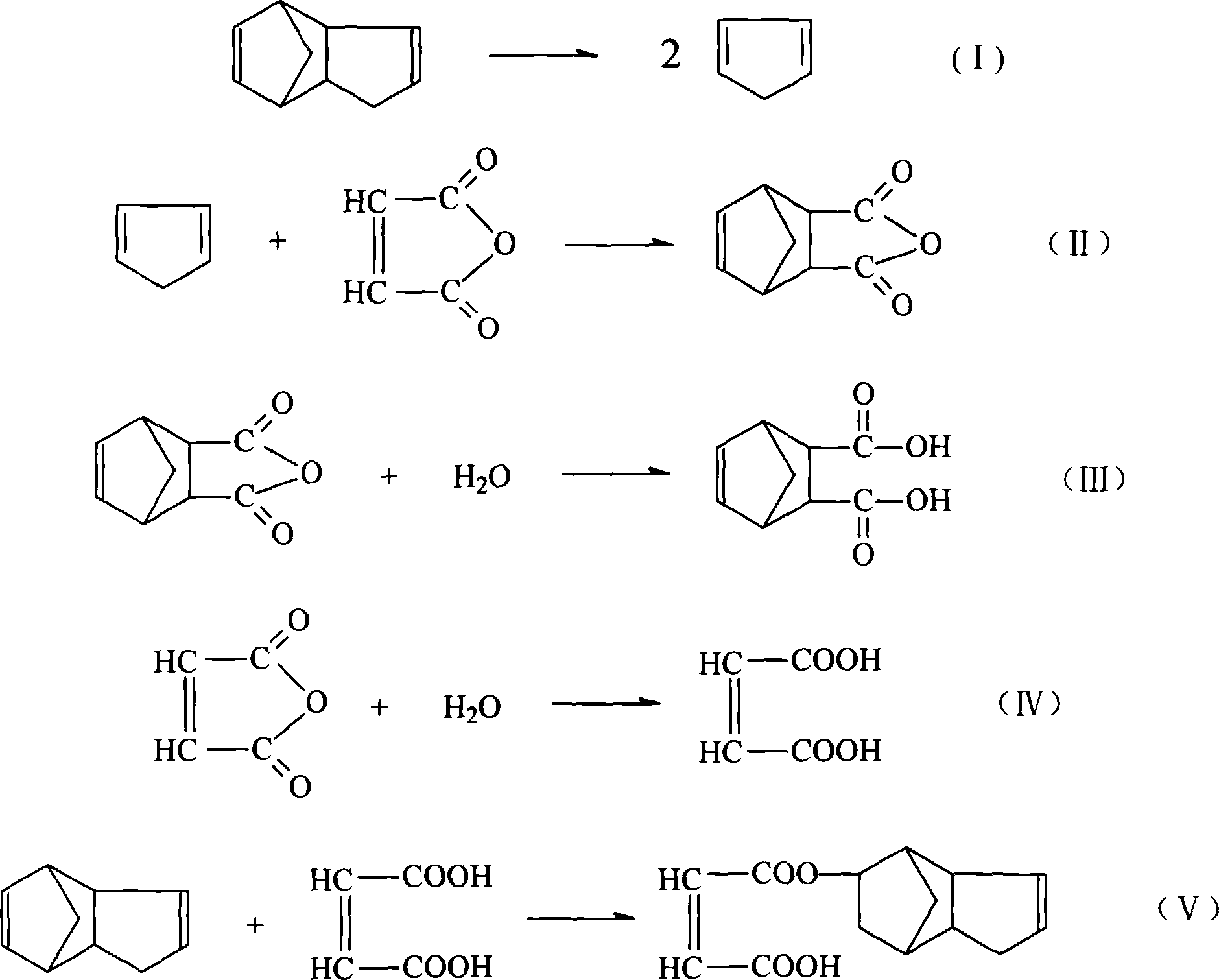

Method used

Image

Examples

Embodiment 1~8

[0022] Under nitrogen protection, 196g of maleic anhydride and the required amount of DCPD were added to a 0.5-liter reactor, and the required amount of catalyst composition phosphoric acid and toluenesulfonic acid were added. Stir and heat up, when the temperature rises above 100°C, add 36g of water, control the reaction temperature to 150-170°C, and react for 2 hours. Add the required amount of propylene glycol and glycerin, gradually raise the temperature, and continuously fractionate the water in the system. When the acid value of the reactant is 90-100mgKOH / g, a polymerization inhibitor p-tert-butylcatechol is added, and the amount of the polymerization inhibitor added is 0.01-0.2wt% based on the total amount of the reactant. Continue the reaction, keep it for about half an hour when the reaction temperature rises to 200-205°C, and stop the reaction until the acid value of the reactant is less than 50mgKOH / g. Cool the reactant to 100-110°C, add the required amount of cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com