Method for preparing interval and configuration adjustable and controllable nano particle ordered array

A nanoparticle and ordered array technology is applied in the field of preparation of nanoparticle ordered arrays with adjustable spacing and configuration, which can solve the problems of high efficiency and low cost, achieve good long-range order, overcome difficult control, Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 A method for preparing an ordered array of nanoparticles with adjustable spacing and configuration, the preparation steps are as follows:

[0024] (1) Dissolve 0.1g of polystyrene-polybutadiene-polystyrene (SBS) triblock polymer in 9.9g of toluene to form a final solution of 1wt% by weight; The solution was spin-coated on a clean quartz glass sheet at 2500rpm; the quartz glass sheet was placed in a weighing bottle, and 5ml of toluene was dropped in it, and then the weighing bottle was sealed with cotton cloth to control the evaporation rate and prepare a template with parallel columnar shapes in the plane ;

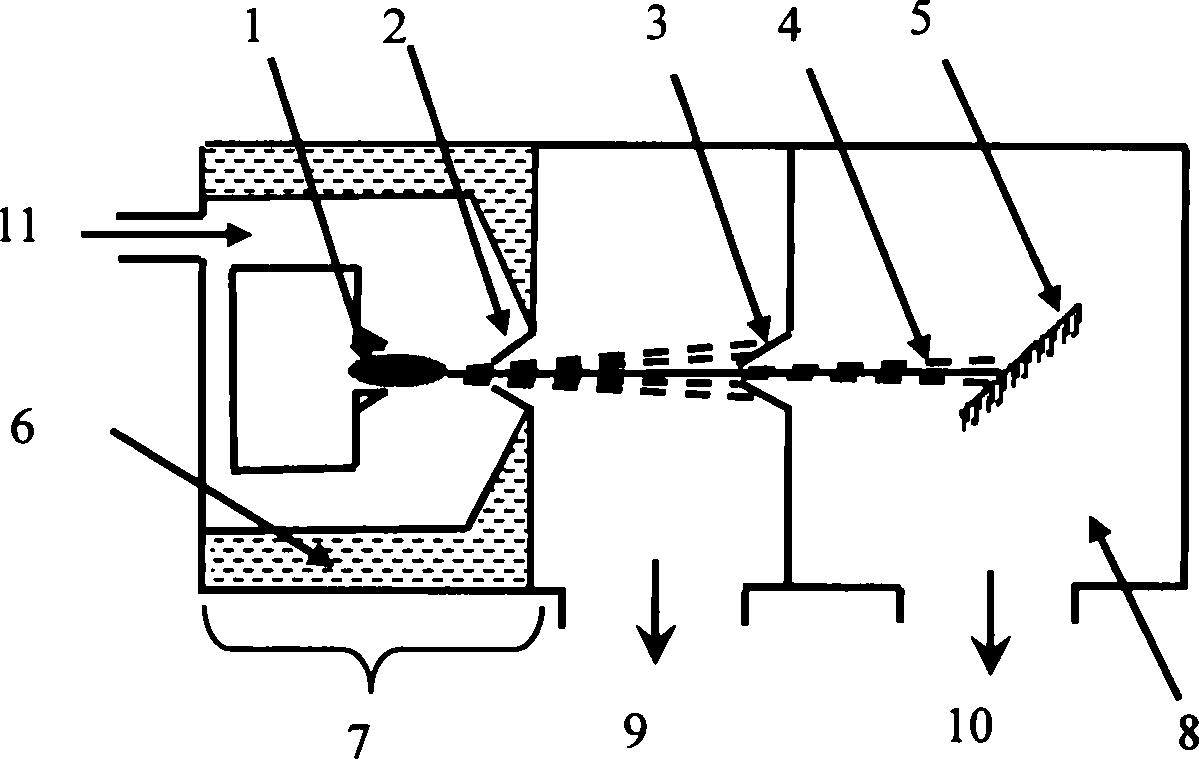

[0025] (2) Fix the template of the above-mentioned ordered pattern on the rotatable substrate holder 5, and then seal the substrate holder 5 in a suitable position in the high vacuum deposition chamber 8;

[0026] (3) Utilize pumping system Rhodes pump 9 and molecular pump 10 to vacuumize, make the vacuum degree of deposition chamber 8 be 5 * 1 -5 At Pa...

Embodiment 2

[0028] Example 2 The preparation method of an ordered array of nanoparticles with adjustable spacing and configuration, the preparation steps are as follows:

[0029] (1) 0.05g polystyrene-polymethyl methacrylate diblock polymer is dissolved in 9.95g chloroform, forms the final solution that percentage by weight is 0.5wt%; 25 μ l final solutions are spun with 2800rpm with micro sampler Apply on a clean silicon wafer; place the silicon wafer in a weighing bottle, drop 10ml of chloroform into it, then seal the weighing bottle with aluminum foil to control the evaporation rate and prepare a template with an ordered porous layered morphology;

[0030] (2) Fix the template of the above-mentioned ordered pattern on the rotatable substrate holder 5, and then seal the substrate holder 5 in a suitable position in the high vacuum deposition chamber 8;

[0031] (3) Utilize pumping system Rhodes pump 9 and molecular pump 10 to evacuate, make the vacuum degree of deposition chamber 8 be 7....

Embodiment 3

[0033] Example 3 The preparation method of an ordered array of nanoparticles with adjustable spacing and configuration, the preparation steps are as follows:

[0034] (1) Dissolve 0.08 g of polystyrene-polyisoprene diblock polymer in 10 g of chloroform to form a final solution with a weight percentage of 1 wt %; use a micro sampler to spin-coat 25 μl of the final solution at 2800 rpm on the cleaning Place the silicon wafer in a weighing bottle, drop 15ml of chloroform in it, then seal the weighing bottle with aluminum foil to control the evaporation rate and then prepare a template with an ordered porous layered morphology;

[0035] (2) Fix the template of the above-mentioned ordered pattern on the rotatable substrate holder 5, and then seal the substrate holder 5 in a suitable position in the high vacuum deposition chamber 8;

[0036] (3) Utilize pumping system Rhodes pump 9 and molecular pump 10 to evacuate, make the vacuum degree of deposition chamber 8 be 7.5 * 10 -5 Pa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com