Supported palladium catalyst as well as preparation method and application thereof

A supported palladium and catalyst technology, applied in the field of Pd catalyst and its preparation, can solve the problems of limiting the hydrogenation rate of alkylanthraquinone derivatives, the yield of hydrogen peroxide, low activity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

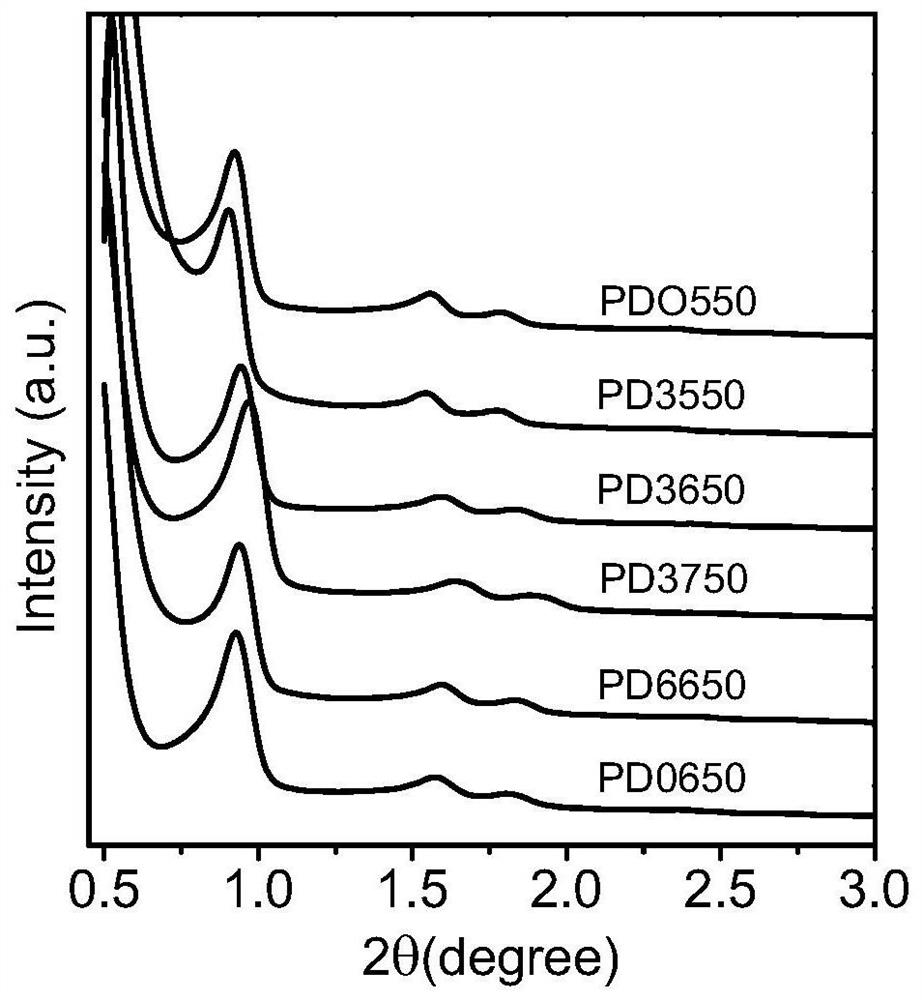

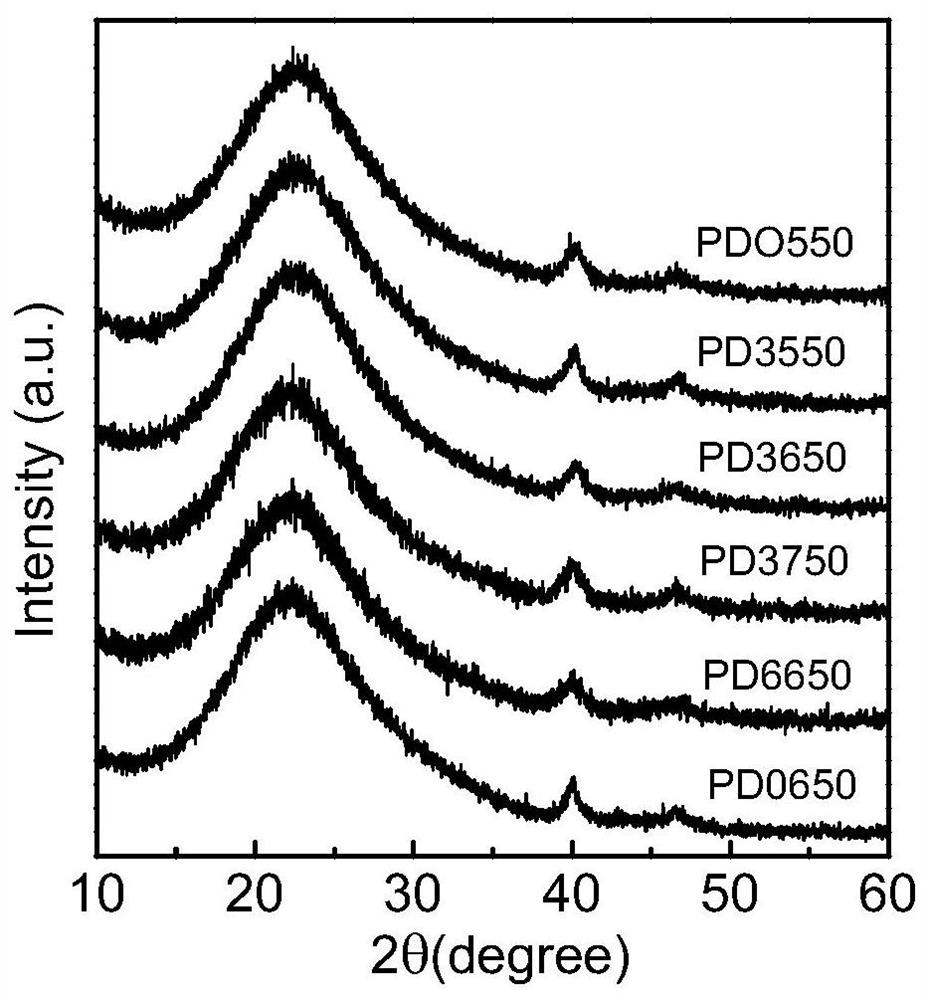

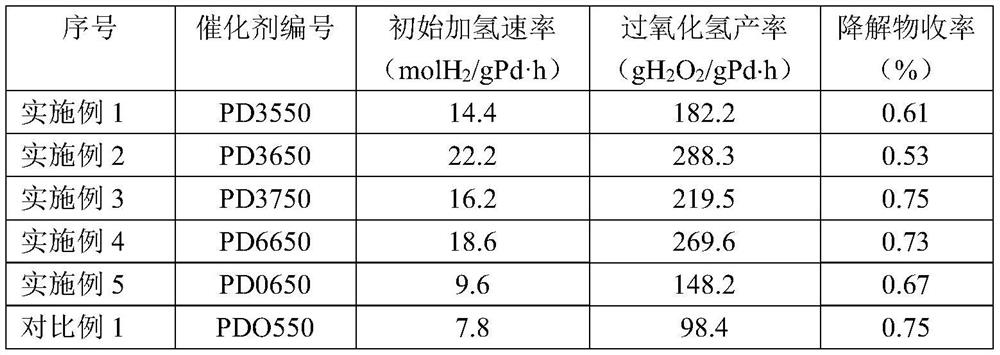

[0040] Dissolve 2.4g of triblock polymer P123 in 90mL of 1.30M HCl solution at 40°C, and then slowly add 4.25g of tetraethyl orthosilicate (TEOS) to obtain a reaction solution with a molar composition of P123:TEOS=1:49. The reaction solution was stirred at 40°C for 24h, then transferred to an autoclave and heated at 100°C for 48h. The reaction solution was filtered, and the obtained solid was washed three times with distilled water, filtered, dried at 110° C. for 12 hours, and then calcined at 550° C. in an argon atmosphere for 6 hours to obtain a mesoporous silica molecular sieve carrier modified with pore wall carbon membrane. The obtained support was impregnated with palladium in an equal volume, calcined in an argon atmosphere at 550°C for 4 hours, and reduced in an atmosphere of 10% hydrogen / 90% argon (volume %) at 250°C for 2 hours to prepare a supported palladium catalyst, which was designated as PD3550. The carbon content and properties of the catalyst supports are sho...

Embodiment 2

[0043] Dissolve 2.4g of triblock polymer P123 in 90mL of 1.30M HCl solution at 40°C, and then slowly add 4.25g of tetraethyl orthosilicate (TEOS) to obtain a reaction solution with a molar composition of P123:TEOS=1:49. The reaction solution was stirred at 40°C for 24h, then transferred to an autoclave and heated at 100°C for 48h. The reaction liquid was filtered, and the obtained solid was washed three times with distilled water, filtered, dried at 110° C. for 12 hours, and then calcined at 650° C. in an argon atmosphere for 6 hours to obtain a mesoporous silica molecular sieve carrier modified with pore wall carbon membrane. The obtained carrier was impregnated with palladium in an equal volume, calcined in an argon atmosphere at 550°C for 4h, and reduced in an atmosphere of 10% hydrogen / 90%argon (volume %) at 250°C for 2h to prepare a supported palladium catalyst, which was designated as PD3650. The carbon content and properties of the catalyst supports are shown in Table 1...

Embodiment 3

[0046] Dissolve 2.4g of triblock polymer P123 in 90mL of 1.30M HCl solution at 40°C, and then slowly add 4.25g of tetraethyl orthosilicate (TEOS) to obtain a reaction solution with a molar composition of P123:TEOS=1:49. The reaction solution was stirred at 40°C for 24h, then transferred to an autoclave and heated at 100°C for 48h. The reaction liquid was filtered, and the obtained solid was washed three times with distilled water, filtered, dried at 110° C. for 12 hours, and then calcined at 750° C. in an argon atmosphere for 6 hours to obtain a mesoporous silica molecular sieve carrier modified with pore wall carbon membrane. The obtained support was impregnated with palladium in an equal volume, calcined in an argon atmosphere at 550°C for 4h, and reduced in an atmosphere of 10% hydrogen / 90% argon (volume %) at 250°C for 2h to prepare a supported palladium catalyst, which was designated as PD3750. The carbon content and properties of the catalyst supports are shown in Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com