Anti-reverse-pole catalyst layer of fuel cell and preparation method and application of anti-reverse-pole catalyst layer

A counter-electrode catalytic layer and fuel cell technology, applied in fuel cells, battery electrodes, electrochemical generators, etc., can solve problems such as membrane electrode performance attenuation, achieve reduced performance attenuation, good application prospects, and promote mass transfer capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] On the other hand, the present invention also provides a method for preparing the anti-reverse electrode catalytic layer of the fuel cell, comprising the following steps:

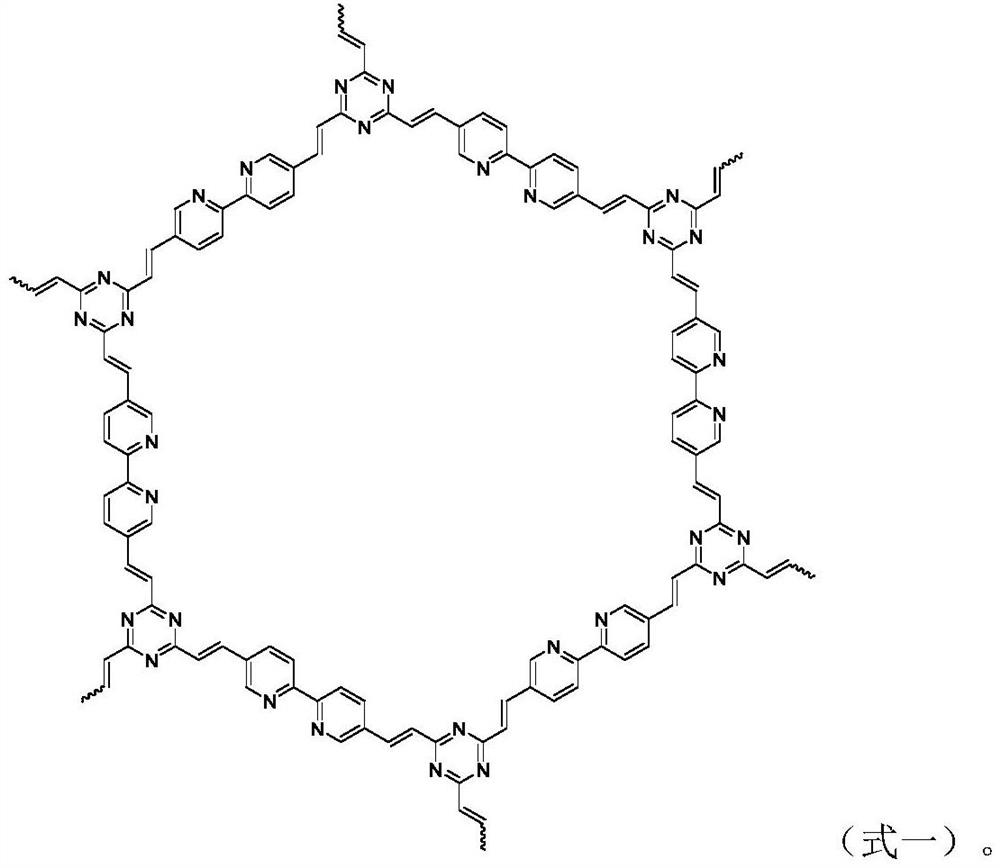

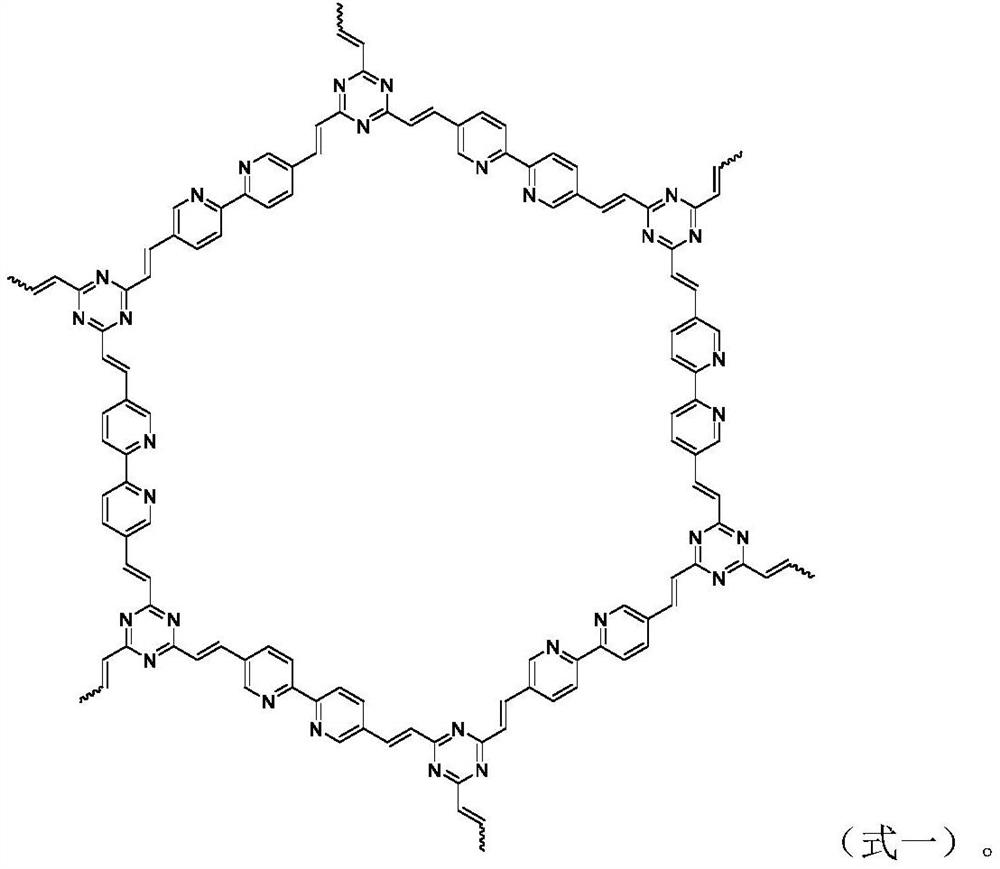

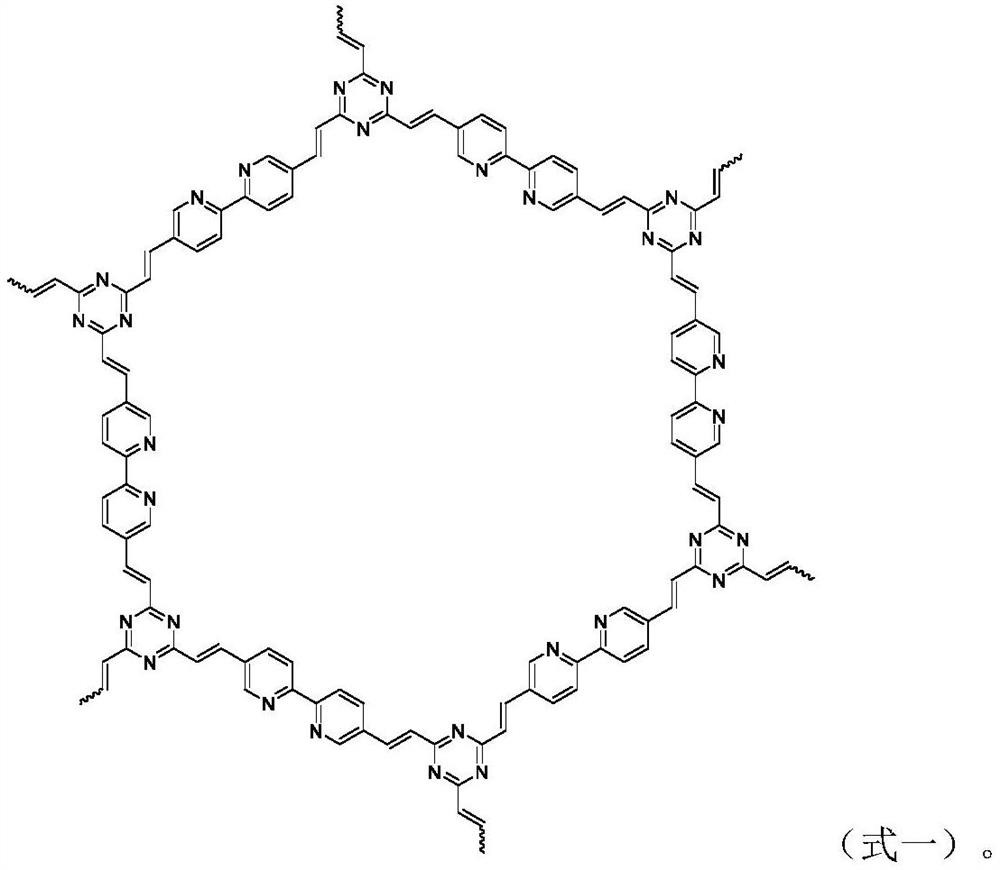

[0044] S1. Add 2,4,6-trimethyl-1,3,5-triazine, 2,2'bipyridine-5,5'-dicarbaldehyde, solvent and catalyst into a glass bottle in turn, and put them into the glass bottle. After being filled with nitrogen, it was sealed, reacted at 100-150 °C for 3-5 days, and quenched with water to obtain a reaction solution; the reaction solution was post-treated and dried at 60-100 °C for 2-4 hours to obtain an anode catalyst carrier (NF -vCOF);

[0045] S2, adding the anode catalyst carrier of step S1 to K 2 PtCl 4 In the solution, stir at 30-80°C for 0.5h, and then sonicate for 0.5h to obtain a mixture, wash the mixture, and dry at 60-100°C for 1-4h to obtain a Pt / NF-vCOF catalyst;

[0046] S3, disperse the Pt / NF-vCOF catalyst, mixed solution and Nafion D2020 of step S2 to obtain a dispersion treatment solution;...

Embodiment 1

[0072] A method for preparing an anti-reverse electrode catalytic layer of a fuel cell, comprising the following steps:

[0073] S1. Synthesis of anode catalyst carrier NF-vCOF: 2,4,6-trimethyl-1,3,5-triazine (24.63mg), 2,2'bipyridine-5,5'-dicarbaldehyde ( 63.66mg), 0.1mL of 50% sodium hydroxide aqueous solution, 0.5mL of methanol and 0.5mL of mesitylene were sequentially added to a high-temperature glass bottle, degassed and filled with nitrogen for 3 times, sealed the glass bottle, and reacted at 150 ° C for 5 days. The reaction was quenched, washed with water, DMF, ethanol, and tetrahydrofuran successively until the washing liquid was in a clear state. After drying at 60 °C for 4 h, NF-vCOF was obtained.

[0074] S2. Preparation of Pt / NF-vCOF catalyst: add 50 mg of NF-vCOF from step S1 to 250 mL of 1 mM K 2 PtCl 4 The aqueous solution was stirred at 30°C for 0.5h, sonicated for 0.5h, washed with water and tetrahydrofuran until the cleaning solution was clear, and dried at...

Embodiment 2

[0078] A method for preparing an anti-reverse electrode catalytic layer of a fuel cell, comprising the following steps:

[0079] S1. Synthesis of anode catalyst carrier NF-vCOF: 2,4,6-trimethyl-1,3,5-triazine (24.63mg), 2,2'bipyridine-5,5'-dicarbaldehyde ( 63.66 mg), 0.1 mL of 30% sodium hydroxide aqueous solution, 0.5 mL of methanol and 0.5 mL of mesitylene were sequentially added to a high-temperature glass bottle, degassed and filled with nitrogen 3 times, sealed the glass bottle, and reacted at 130 ° C for 5 days. The reaction was quenched, washed with water, DMF, ethanol, and tetrahydrofuran successively until the washing liquid was in a clear state, and dried at 70 °C for 3 h to obtain NF-vCOF.

[0080] S2. Preparation of Pt / NF-vCOF catalyst: add 50 mg of NF-vCOF from step S1 to 250 mL of 1 mM K 2 PtCl 4 The aqueous solution was stirred at 40 °C for 0.5 h, and after sonication for 0.5 h, washed with water and tetrahydrofuran until the cleaning solution was clear, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com