Preparation of silver phosphate two-dimensional ordered nanonet film and method thereof by gas-liquid interface method

A gas-liquid interface, silver phosphate technology, used in chemical instruments and methods, hybrid capacitor electrodes, physical/chemical process catalysts, etc. There are many problems, so as to achieve the effect of uniform film thickness, uniform film thickness and good crystallinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a silver phosphate two-dimensional ordered nanonet film at a gas-liquid interface, comprising the following steps:

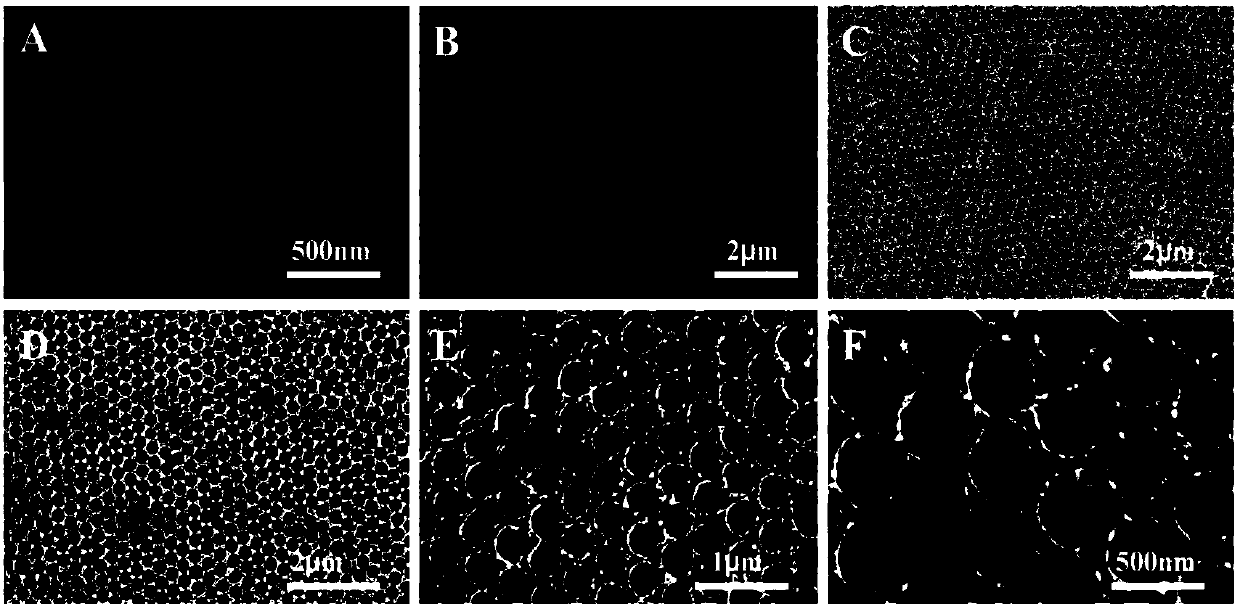

[0025] (1) will contain polystyrene balls ( figure 1 A) ethanol-water (V 乙醇 :V 水 =1:1) mixed solution, slowly added dropwise to the water surface, the polystyrene balls diffused and assembled into an ordered monolayer film driven by surface tension ( figure 1 B);

[0026] (2) Take the desiccator as the reaction vessel, place a petri dish filled with 30 mmol / L silver nitrate solution on the upper layer, and use the smooth and clean glass sheet as the base to assemble the polystyrene ball monolayer film obtained in (1) Transfer to the Petri dish; place 5 grams of finely ground dimethylaminoborane powder and 3 milliliters of 5 mol / liter nitric acid aqueous solution in the lower layer. After about 12 hours of reaction, the silver-polystyrene two-dimensional ordered nano-network film can be obtained. according to figure 2 As shown...

Embodiment 2

[0028] A method for preparing a silver phosphate two-dimensional ordered nanonet film at a gas-liquid interface, comprising the following steps:

[0029] (1) will contain polystyrene balls ( figure 1 A) ethanol-water (V 乙醇 :V 水 =1:1) mixed solution, slowly added dropwise to the water surface, the polystyrene balls diffused and assembled into an ordered monolayer film driven by surface tension ( figure 1 B);

[0030] (2) Take the desiccator as the reaction vessel, place a petri dish filled with 30 mmol / L silver nitrate solution on the upper layer, and use the smooth and clean glass sheet as the base to assemble the polystyrene ball monolayer film obtained in (1) Transfer to the Petri dish; place 5 grams of finely ground dimethylaminoborane powder and 3 milliliters of 5 mol / liter nitric acid aqueous solution in the lower layer. After about 12 hours of reaction, silver-polystyrene two-dimensional ordered nanonet film ( figure 1 C).

[0031] (3) Pipette the mixed reaction so...

Embodiment 3

[0034] A method for preparing a silver phosphate two-dimensional ordered nanonet film at a gas-liquid interface, comprising the following steps:

[0035] (1) will contain polystyrene balls ( figure 1 A) ethanol-water (V 乙醇 :V 水 =1:1) mixed solution, slowly added dropwise to the water surface, the polystyrene balls diffused and assembled into an ordered monolayer film driven by surface tension ( figure 1 B);

[0036] (2) Take the desiccator as the reaction vessel, place a petri dish filled with 30 mmol / L silver nitrate solution on the upper layer, and use the smooth and clean glass sheet as the base to assemble the polystyrene ball monolayer film obtained in (1) Transfer to the Petri dish; place 5 grams of finely ground dimethylaminoborane powder and 3 milliliters of 5 mol / liter nitric acid aqueous solution in the lower layer. After about 12 hours of reaction, silver-polystyrene two-dimensional ordered nanonet film ( figure 1 C).

[0037] (3) Pipette the mixed reaction so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com