Method for separating and preparing 5'-nucleotide using emulated moving bed

A technology for simulating moving bed and nucleotides, applied in the field of biological product processing, can solve the problems of difficult scale, cumbersome operation, intermittent operation, etc., and achieve the effect of improving separation efficiency, ensuring high quality and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

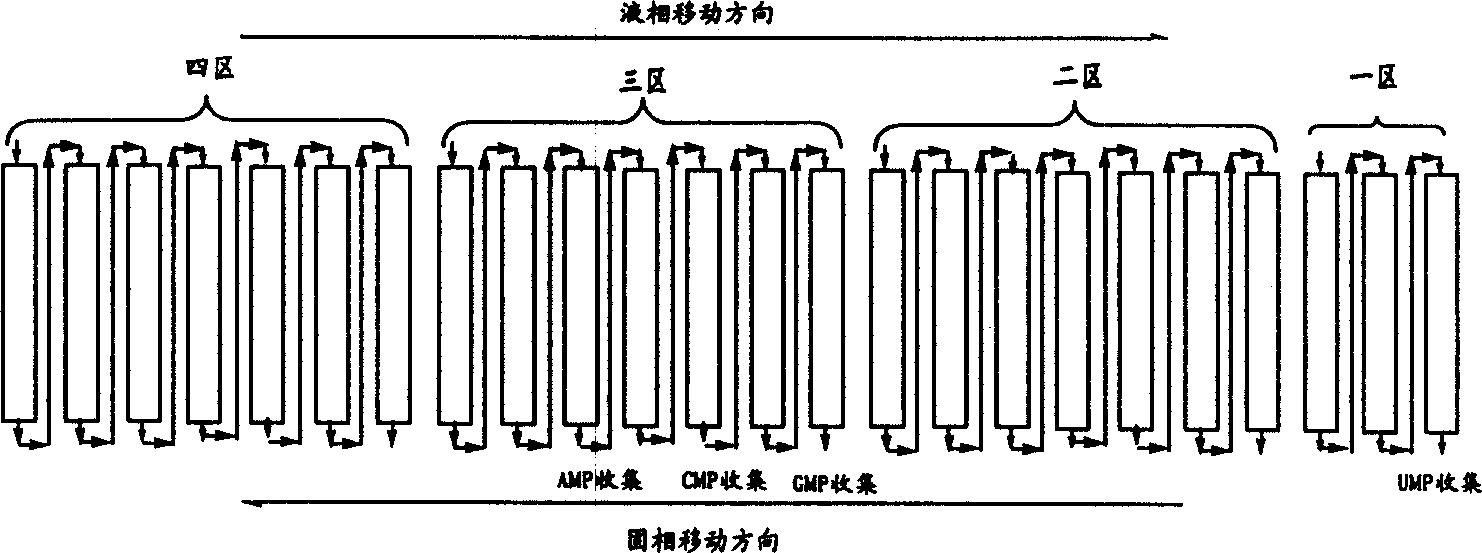

[0036]The sample concentration of the nucleotide enzymatic hydrolysis solution was 30 g / L. Pack 24 ion-exchange columns with the wet packing method, each ion-exchange resin column is filled with 200 grams of 001×6 type resin, the resin particle size is 100-150 mesh, and the diameter-to-height ratio of the column is 1:5. The following process is used for separation, 2 ion-exchange columns in the first zone, 7 ion-exchange columns in the second zone, 7 ion-exchange columns in the third zone, and 7 ion-exchange columns in the fourth zone. Then, the clarified nucleotide solution is loaded onto the column for adsorption from the adsorption area, and the sample loading flow rate is 10ml / min. Each zone was eluted with pH 5.0 deionized water, and the flow rates were: 10ml / min for the first zone, 18ml / min for the second zone, 17ml / min for the third zone, and 35ml / min for the fourth zone. The three outlets of the desorption zone collect UMP, GMP, CMP and AMP solutions respectively, and...

Embodiment 2

[0038] The sample concentration of nucleotidase hydrolysis liquid was 25g / L. Pack 24 ion-exchange columns by wet column packing method, each ion-exchange resin column is filled with 200 grams of 001×7 type resin, the resin particle size is 100-150 mesh, and the diameter-to-height ratio of the column is 1:5, and adopt The following process is used for separation, 3 ion-exchange columns in the first zone, 6 ion-exchange columns in the second zone, 7 ion-exchange columns in the third zone, and 8 ion-exchange columns in the fourth zone. Then, the clarified nucleotide solution is loaded onto the column for adsorption from the adsorption area, and the sample loading flow rate is 10ml / min. Each zone was eluted with pH 5.0 deionized water, and the flow rates were: 15ml / min for the first zone, 23ml / min for the second zone, 22ml / min for the third zone, and 43ml / min for the fourth zone. The three outlets of the desorption zone collect UMP, GMP, CMP and AMP solutions respectively, and th...

Embodiment 3

[0040] The sample concentration of the nucleotide enzymatic hydrolysis solution was 31 g / L. Pack 24 ion-exchange columns with the wet packing method, each ion-exchange resin column is filled with 200 grams of 001×5 type resin, the resin particle size is 120-150 mesh, and the diameter-to-height ratio of the column is 1:5. The following process is used for separation, 2 ion-exchange columns in the first zone, 7 ion-exchange columns in the second zone, 7 ion-exchange columns in the third zone, and 8 ion-exchange columns in the fourth zone. Then, the clarified nucleotide solution is loaded onto the column for adsorption from the adsorption area, and the sample loading flow rate is 10ml / min. Each zone was eluted with pH 5.0 deionized water, and the flow rates were: 13ml / min for the first zone, 22ml / min for the second zone, 21ml / min for the third zone, and 41ml / min for the fourth zone. The three outlets of the desorption zone collect UMP, GMP, CMP and AMP solutions respectively, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com