Motor vehicle exhaust catalytic converter, and its preparing method

A technology for catalytic converters and motor vehicles, used in exhaust devices, mechanical equipment, machines/engines, etc., can solve the problems of reduced catalytic activity, high cost, unsuitable coating, etc., to improve the purification effect and prolong the service life , combined with a strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] A motorcycle exhaust catalytic converter

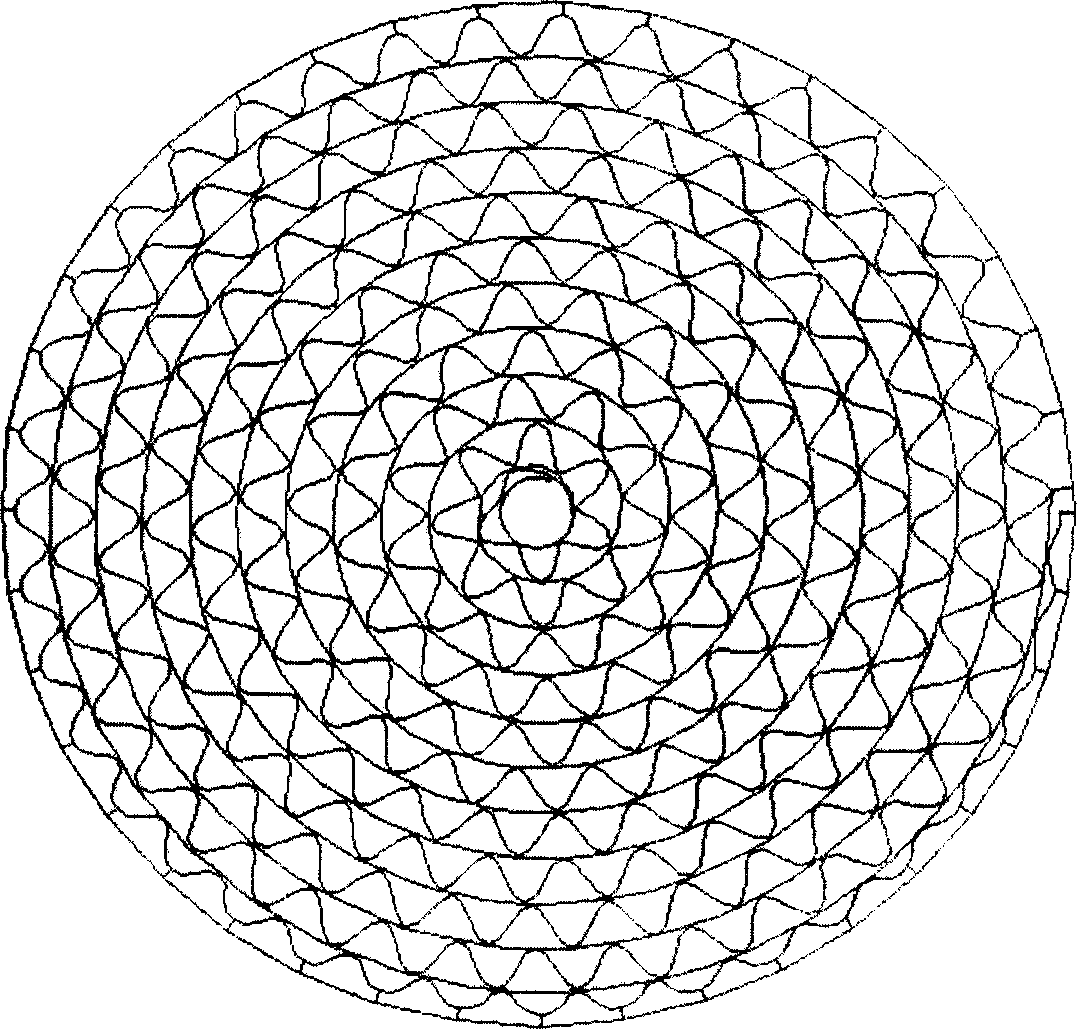

[0047] This motorcycle exhaust catalytic converter comprises a carrier shell, a catalyst carrier placed in the carrier shell, and a leading fluid and a rear guiding fluid respectively placed on the front and back of the catalyst carrier, and the catalyst carrier is composed of a flat substrate and a It is a concentric coiled metal honeycomb carrier formed by winding corrugated carrier plates with each other. The attached drawing is a schematic diagram of its section structure.

[0048] The catalyst carrier is a concentric coiled metal honeycomb carrier made of a hot-dip aluminum-coated thin steel plate as a precursor by a micro-arc oxidation ceramic film process, and meets the general technical requirements for motorcycle catalytic converters stipulated in national industry standards.

[0049] The catalyst coating on the catalyst carrier is a noble metal and rare earth composite catalyst coating, which will be made of rare eart...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com