Process for preparing silane crosslinked polyethylene by room temperature crosslinking

A technology of cross-linked polyethylene and silane cross-linking, which is applied in the field of preparation of silane cross-linked polyethylene by cross-linking at room temperature, can solve problems such as complex operation, affecting product performance, and difficult conditions to control, and achieve high product yield and excellent product performance , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

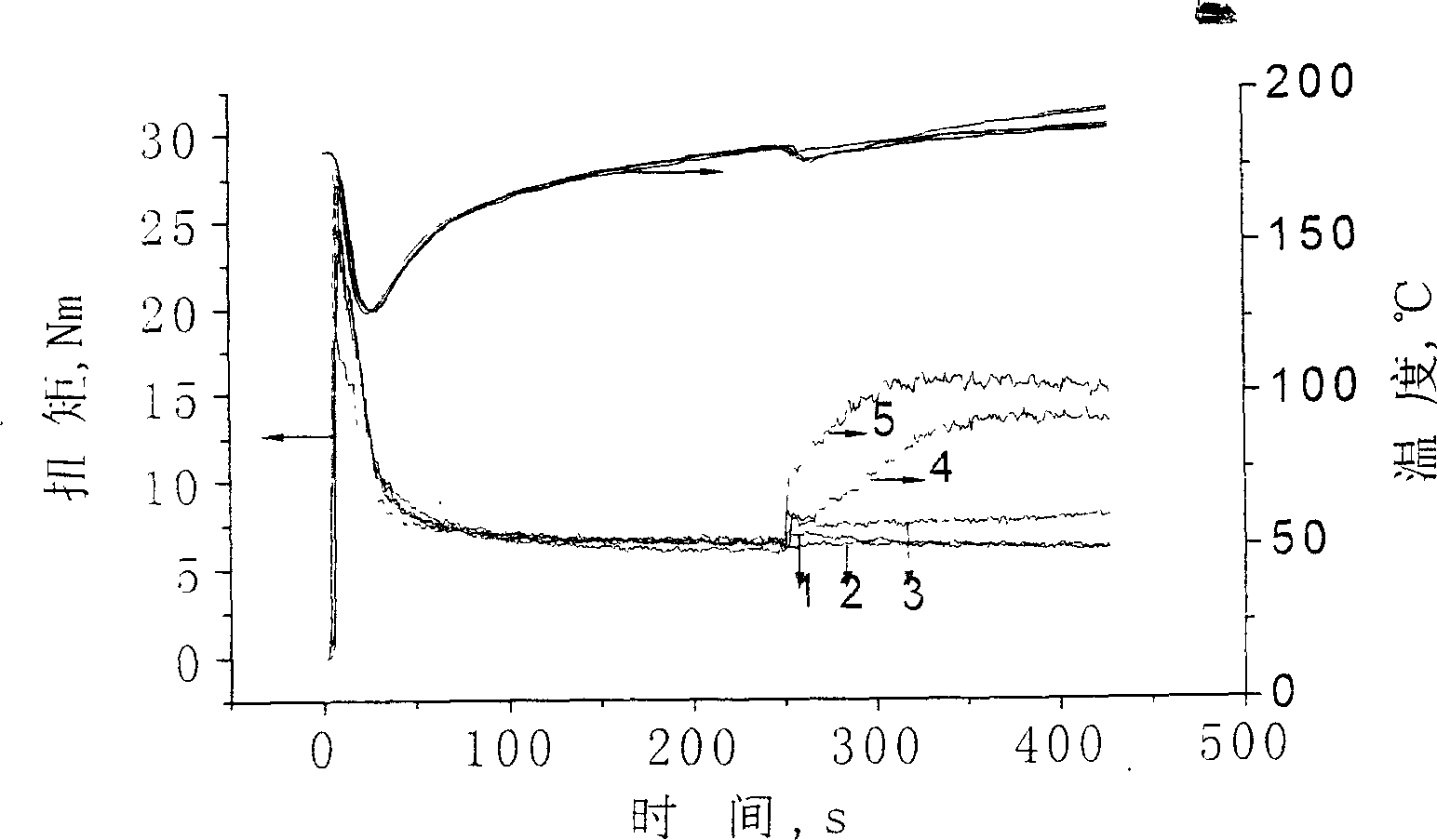

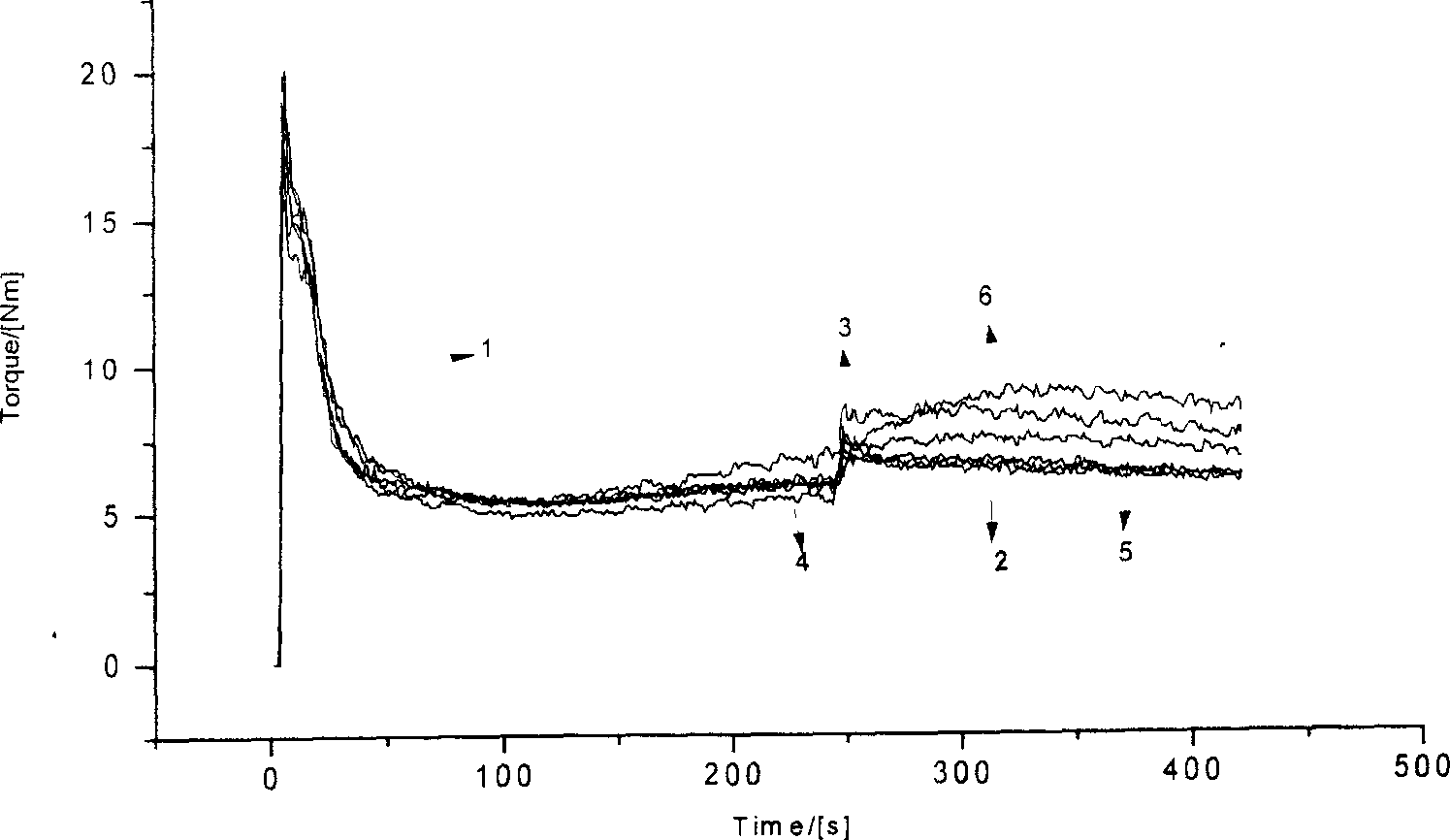

Image

Examples

Embodiment 1

[0041] Embodiment 1: the influence of different polyethylene resins on grafting rate

[0042] Dissolve 0.3 gram of initiator dicumyl peroxide (DCP) into chelate of 3 gram of vinyltriethoxysilane, 1 gram of ethyltrimethoxysilane, 1 gram of tetrabutoxytitanane and ethyl acetoacetate compound (mass ratio 1:1), then mixed with 100 grams of different types of polyethylene resins, fed into the extruder at 160°C for melting, grafting and granulation, and baked at 80°C for 1 hour to obtain the grafted material. Get 1 gram of graft material and wrap it up with filter paper, put into the reaction flask with the band reflux condenser that adds 100ml chloroform, heat and reflux for 8 hours, change chloroform once every 4 hours, take out the filter paper bag after finishing, dry Weigh after drying, calculate the grafting rate, the silane grafting rate of different polyethylene resins is shown in Table 1:

[0043] polyethylene resin

Embodiment 2

[0044] Embodiment 2: the impact of different alkenyl alkoxysilanes on polyethylene grafting ratio

[0045]Chelation of 0.1 g of initiator dicumyl peroxide (DCP) into 5 g of different alkenylalkoxysilanes and 1.5 g of propyltrimethoxysilane, 1.5 g of tetrabutoxytitanane with acetylacetone (mass ratio 1: 1) mixed solution, then mixed with 100 grams of LLDPE, into the extruder at 160 ℃ of melting grafting granulation, 80 ℃ of baking 1 hour seal preservation to obtain the graft material; get the graft material 1 Wrap it with filter paper, put it into a reaction flask with 100ml of chloroform and a reflux condenser, heat and reflux for 8 hours, change the chloroform once every 4 hours, take out the filter paper bag after the end, weigh after drying, and calculate Grafting rate, the grafting rate of different alkenyl alkoxysilanes in LLDPE is shown in Table 2:

[0046] alkenyl alkoxy silicon

Embodiment 3

[0047] Example 3: Effect of chelates of methyltrimethoxysilane and tetrabutoxytitanane with ethyl acetoacetate on the gel content of silane-grafted polyethylene

[0048] Chelation of 0.1 g of initiator dicumyl peroxide (DCP) into 3 g of vinyltriethoxysilane and different amounts of methyltrimethoxysilane and tetrabutoxytitanes with ethyl acetoacetate (Methyltrimethoxysilane and tetrabutoxytitanane chelate mass ratio 1: 1) mixed solution, then mixed with 100 grams of LDPE, into the extruder at 170 ℃ melting grafting granulation, 80 Dry at ℃ for 1 hour and seal the grafted material to obtain the grafted material; take 1 gram of the grafted material and wrap it with filter paper, put it into a reaction bottle with a reflux condenser added with 100ml of toluene, heat and reflux for 8 hours, change the toluene once every 4 hours, and end Finally, the filter paper bag was taken out, weighed after drying, and the gel content was calculated. The chelates (mass ratio 1: 1) of different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com