Preparation method of InP quantum point

A quantum dot, transparent technology, applied in the field of compound semiconductor nanomaterial preparation, can solve the problems affecting the research of III-V semiconductor nanomaterials, strict preparation conditions and operation requirements, restricting the development of semiconductor devices, etc., and achieves low equipment cost and uniform size. , the effect of eliminating the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

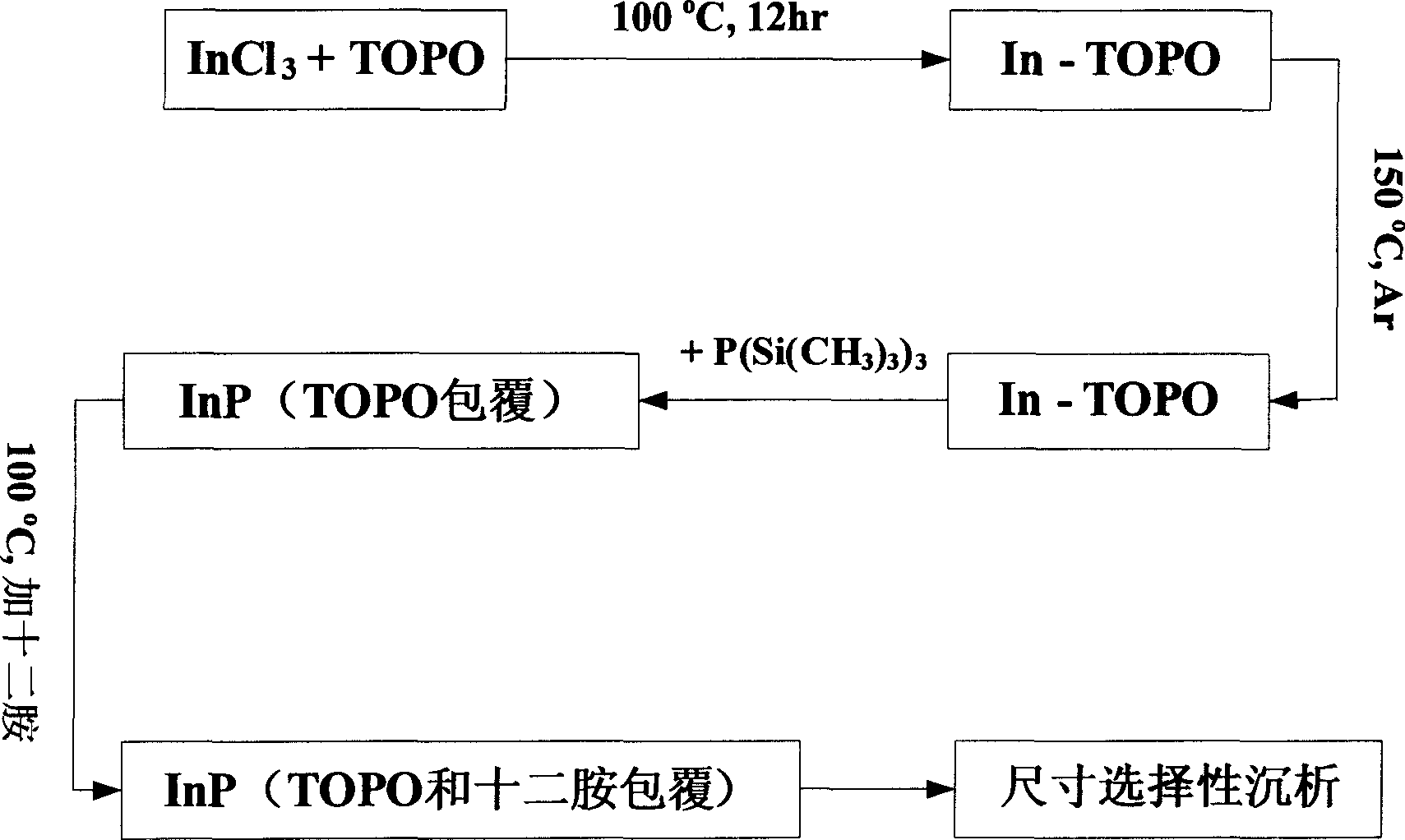

[0037] (1) Rough quantum dot synthesis stage:

[0038] (1.1) Weigh 0.7g InCl in a three-necked flask 3 And 10g TOPO, through argon to exhaust the air, heated to 100°C under argon atmosphere to form a colorless transparent solution, this solution was maintained at 100°C for 12 hours.

[0039] (1.2) Raise the temperature of the solution in the flask to 150° C., and blow argon into the solution for 10 minutes.

[0040] (1.3) Measure 0.6mL P(Si(CH 3 ) 3 ) 3 (0.002mol), quickly injected into the flask.

[0041] (1.4) The temperature of the reaction solution in the flask was slowly raised to 265° C., and maintained at this temperature for 6 days.

[0042] (1.5) The temperature of the solution is lowered to 100° C., inject 0.5 mL of dodecylamine, and keep at this temperature for 3 days. Remove the argon protection.

[0043] (2) Separation and purification stage:

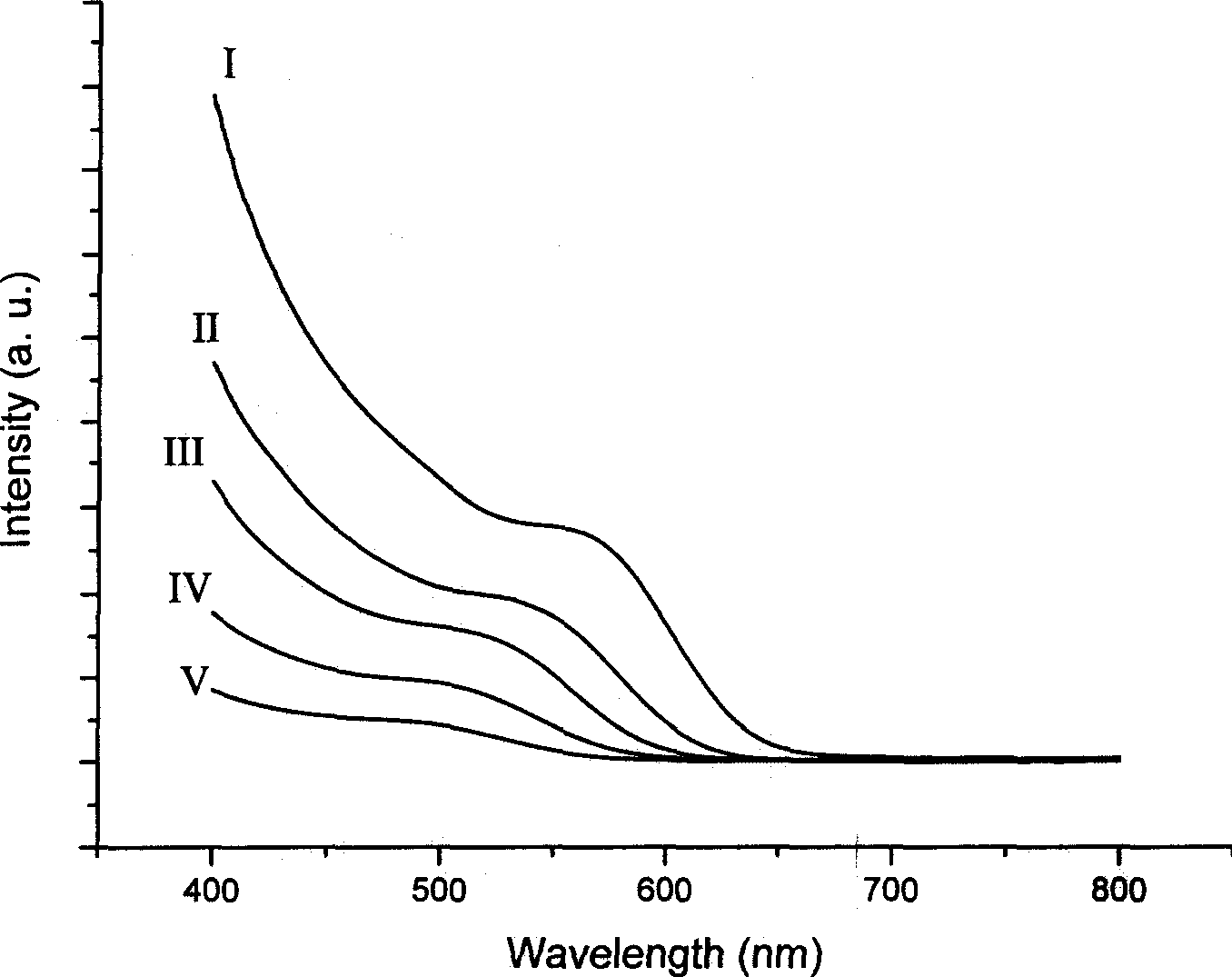

[0044] (2.1) Add toluene equal to the volume of the solution in the bottle to the reaction flask, and all the sub...

example 2

[0053] (1) Rough quantum dot synthesis stage:

[0054] (1.1) Weigh 0.3g InCl in a three-necked flask 3 And 10g TOPO, through argon to exhaust the air, heated to 110°C under argon atmosphere to form a colorless transparent solution, this solution was maintained at 110°C for 10 hours.

[0055] (1.2) Raise the temperature of the solution in the flask to 170° C., and blow argon into the solution for 12 minutes.

[0056] (1.3) Measure 0.3mL P(Si(CH 3 ) 3 ) 3 (0.001mol), quickly injected into the flask.

[0057] (1.4) The temperature of the reaction solution in the flask was slowly raised to 270° C. and maintained at this temperature for 3 days.

[0058] (1.5) The temperature of the solution is lowered to 80° C., inject 0.4 mL of dodecylamine, and keep at this temperature for 2 days. Remove the argon protection.

[0059] (2) Separation and purification stage:

[0060] This stage is exactly the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com