Production method of water-absorbent resin, water-absorbent resin, and usage of water-absorbent resin

A manufacturing method and water-absorbing technology, which are applied in the manufacture of water-absorbing resins and the fields of water-absorbing resins and their applications, can solve the problems of coloring of water-absorbing resins, large deviations in the amount of residual monomers, and the amount of residual monomers not being reduced to the desired level the degree of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

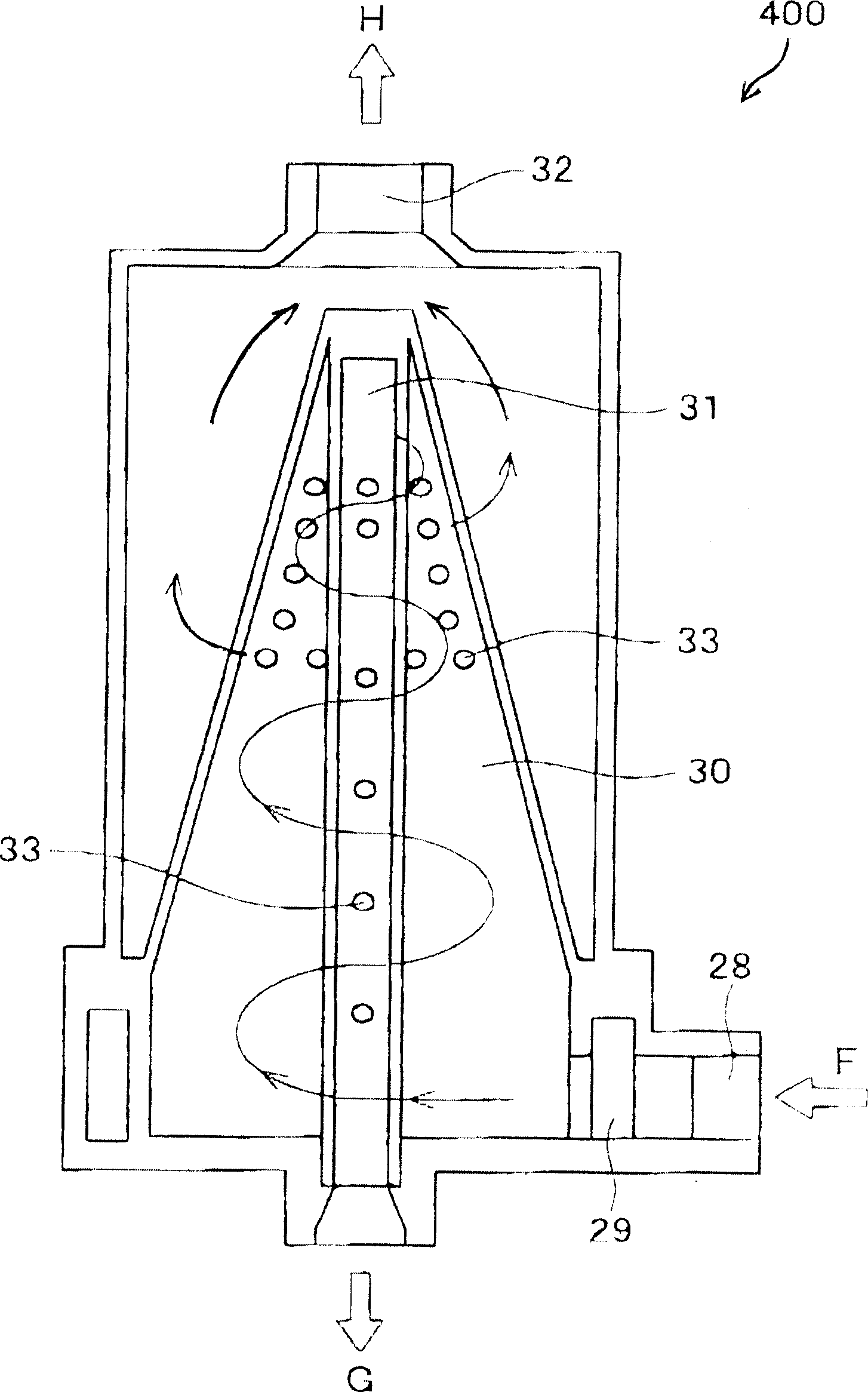

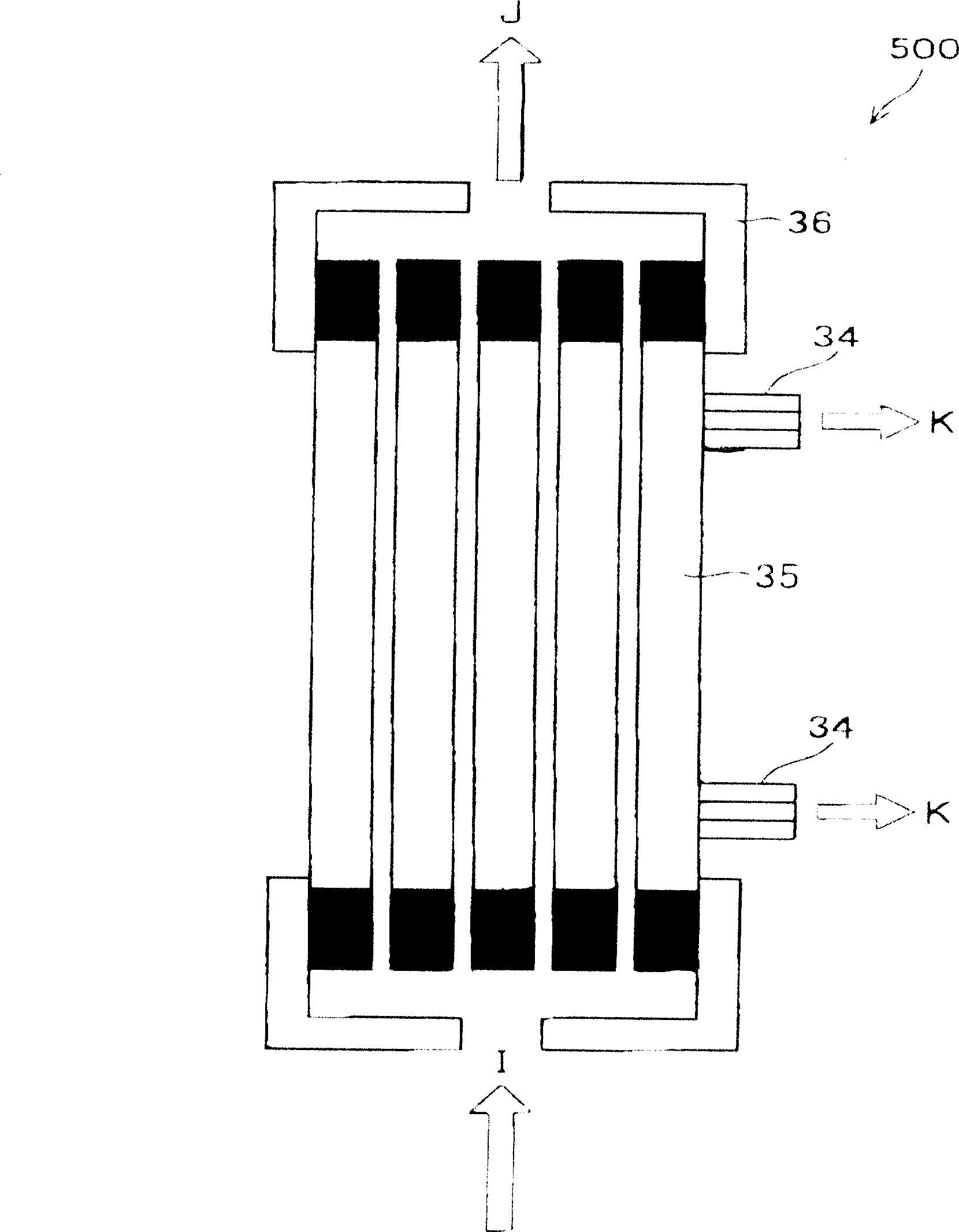

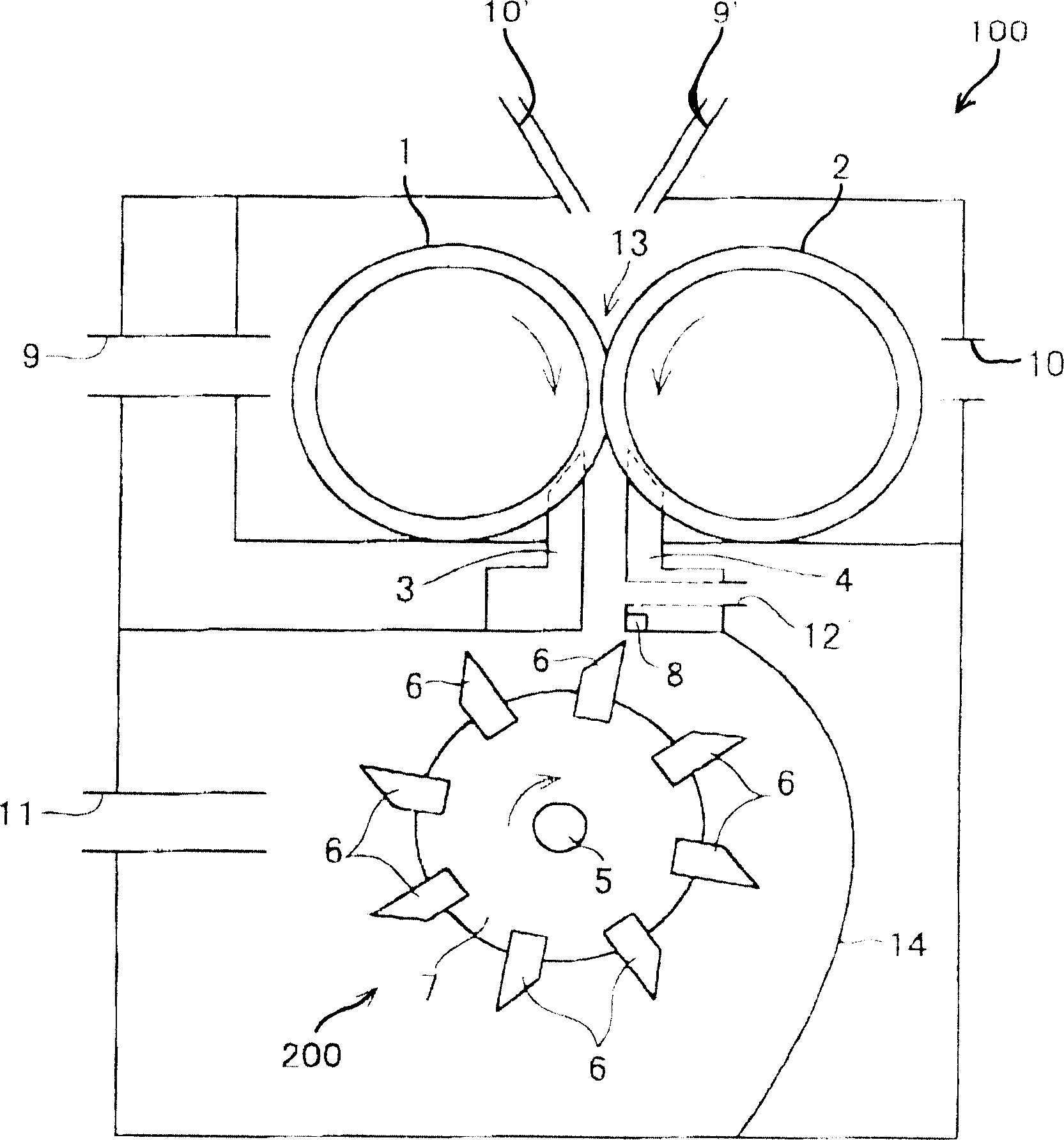

[0056] In Embodiment 1, the production method of the water-absorbent resin of the present invention includes:

[0057] (1) The ethylenically unsaturated monomer containing acrylic acid and / or acrylate in an amount of 30 mol% to 100 mol% (excluding the crosslinking agent) is polymerized in flakes to obtain a moisture content of 40 A polymerization process of a hydrogel polymer having a mass % or more to 70 mass % or less;

[0058] (2) The above-mentioned hydrogel-like polymer is cut into particles having a mass average particle diameter of 3 mm to 10 mm, and a shape of not less than tetrahedron and not more than 12-hedron, which accounts for the mass of the hydrogel-like polymer. Cutting process of 50 mass% or more to 100 mass% or less, or drying the above-mentioned hydrogel-like polymer to a water content of 5 mass% or more to 60 mass% or less, and then cutting into a mass average particle diameter of 2mm to 10mm A step of cutting the following particles in the shape of not l...

Embodiment 1

[0329] A polyethylene glycol diacrylate (n=9) aqueous solution containing 254.50 g of 37% by mass of 254.50 g of sodium acrylate, 29.50 g of acrylic acid, 0.747 g of 10% by mass of polyethylene glycol diacrylate (n=9), 20.26 g of ion-exchanged water, and 10% by mass of polyethylene glycol diacrylate was prepared. A monomer aqueous solution of 6.25 g of an alcohol (trade name: polyethylene glycol 6,000, manufactured by Kanto Chemical Co., Ltd.) aqueous solution. That is, an ethylenically unsaturated monomer containing 100 mol% of acrylic acid and sodium acrylate (excluding the crosslinking agent) was prepared. Nitrogen is poured into the monomer aqueous solution so that the dissolved oxygen concentration in the aqueous solution is less than or equal to 0.1 ppm.

[0330] Next, 1.41 g of a 1.0 mass % acrylic acid solution of hydroxycyclohexyl phenone (trade name: Irgacure 184; manufactured by Ciba Specialty Chemicals Co., Ltd.) and 1.41 g of a 3.0 mass % sodium persulfate aqueous...

Embodiment 2

[0336] A polyethylene glycol diacrylate (n=9) solution containing 407.2 g of 37 mass % sodium acrylate aqueous solution 407.2 g, acrylic acid 47.2 g, 10 mass % polyethylene glycol diacrylate (n=9) aqueous solution 1.195 g, ion-exchanged water 0.35 g, 10 mass % polyethylene diacrylate was prepared. A monomer aqueous solution of 10.00 g of an alcohol (trade name: polyethylene glycol 6,000, manufactured by Kanto Chemical Co., Ltd.) aqueous solution. That is, an ethylenically unsaturated monomer containing 100 mol% of acrylic acid and sodium acrylate (excluding the crosslinking agent) was prepared. Nitrogen is poured into the monomer aqueous solution so that the dissolved oxygen concentration in the aqueous solution is less than or equal to 0.1 ppm.

[0337] Next, 2.256 g of a 1.0 mass % acrylic acid solution of hydroxycyclohexyl phenone (trade name: Irgacure 184; manufactured by Ciba Specialty Chemicals Co., Ltd.) and 2.256 g of a 3.0 mass % sodium persulfate aqueous solution wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com