Metal plating layer

A metal coating and coating technology, which is applied in the direction of metal material coating process, coating, sputtering coating, etc., can solve the problems of unevenness, plastic material separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

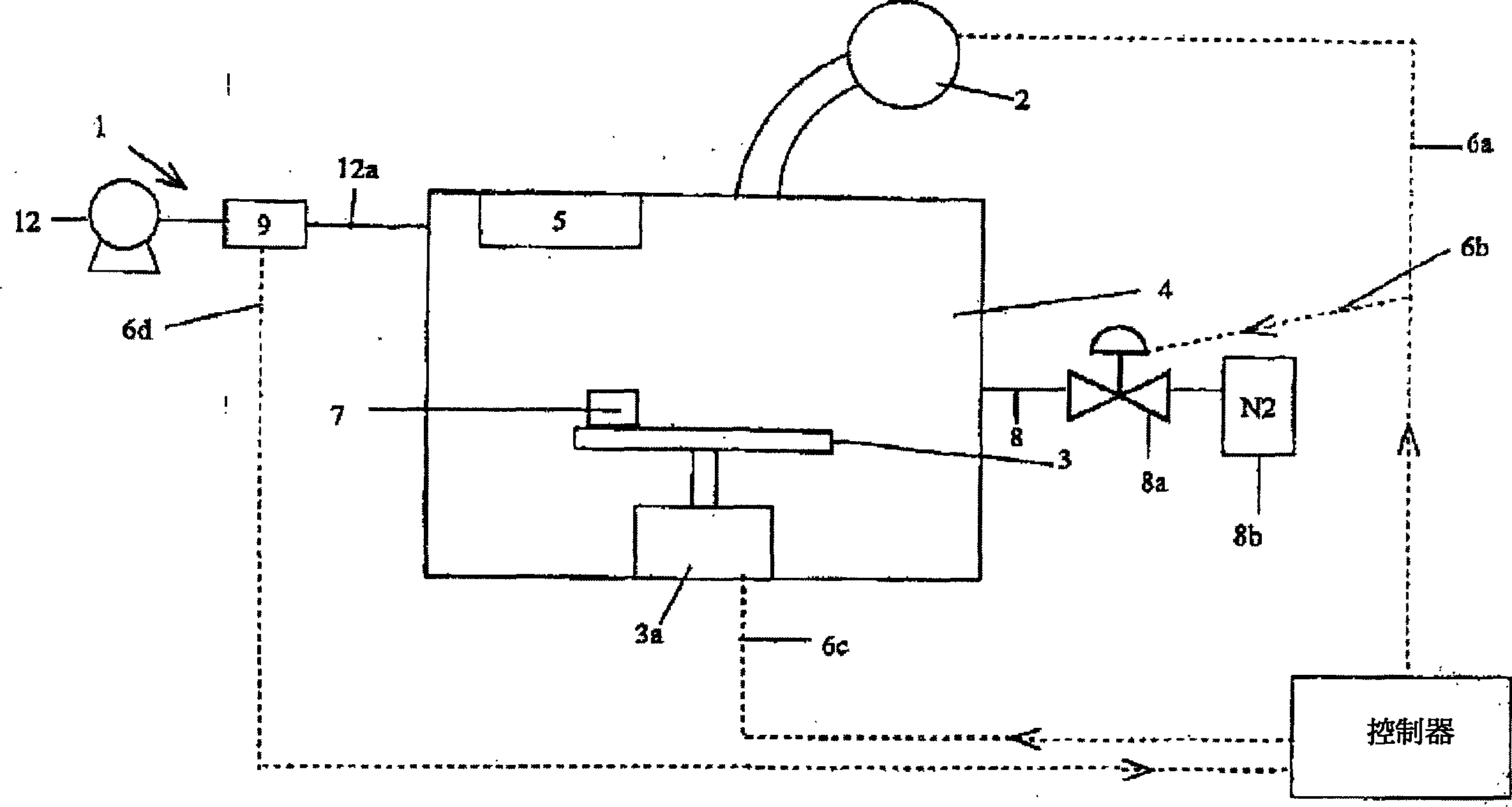

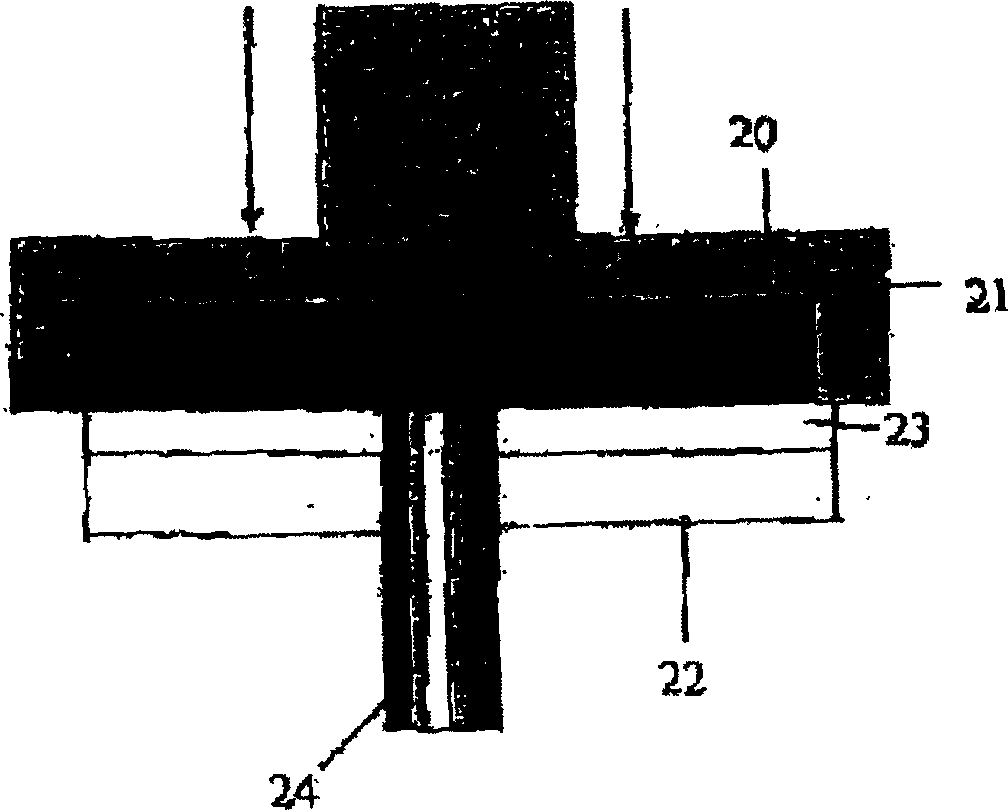

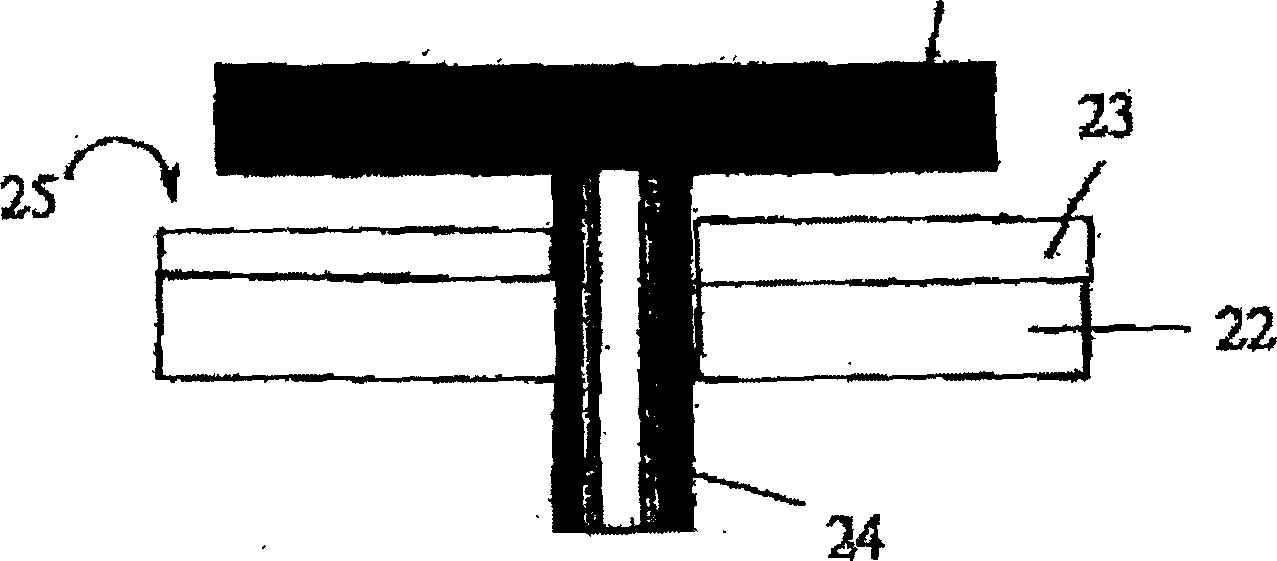

[0061] Exemplary, non-limiting aspects of metallization methods and metallization materials are disclosed herein. The disclosed features relate to coatings, methods of coating and their use, the coatings being based on alternating metal and metal-gas compound coatings. Disclosed features also relate to the use of filtered cathodic vacuum arc (FCVA) techniques for metal-gas compound coatings, and combinations of these features.

[0062] The gas may contain one or more atoms selected from nitrogen (N), oxygen (O), hydrogen (H), sulfur (S) and mixtures thereof. The gas may be in the form of a pure gas such as pure nitrogen (N 2 ), hydrogen (H 2 ) or oxygen (O 2 ), alternatively, the gas may contain molecules of gas atoms. Exemplary molecules of gas atoms include ammonia, nitrogen oxides, sulfur oxides, nitrous oxide, and hydrogen sulfide.

[0063] Preferably, the metal-gas compound is a compound of a metal and one or more gas atoms. A feature of the invention is that the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com