High efficiency deep ultraviolet light-emitting diode

A light-emitting diode, deep ultraviolet technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as P-type conduction difficulties, and achieve the effects of increasing luminous efficiency, improving luminous efficiency, and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

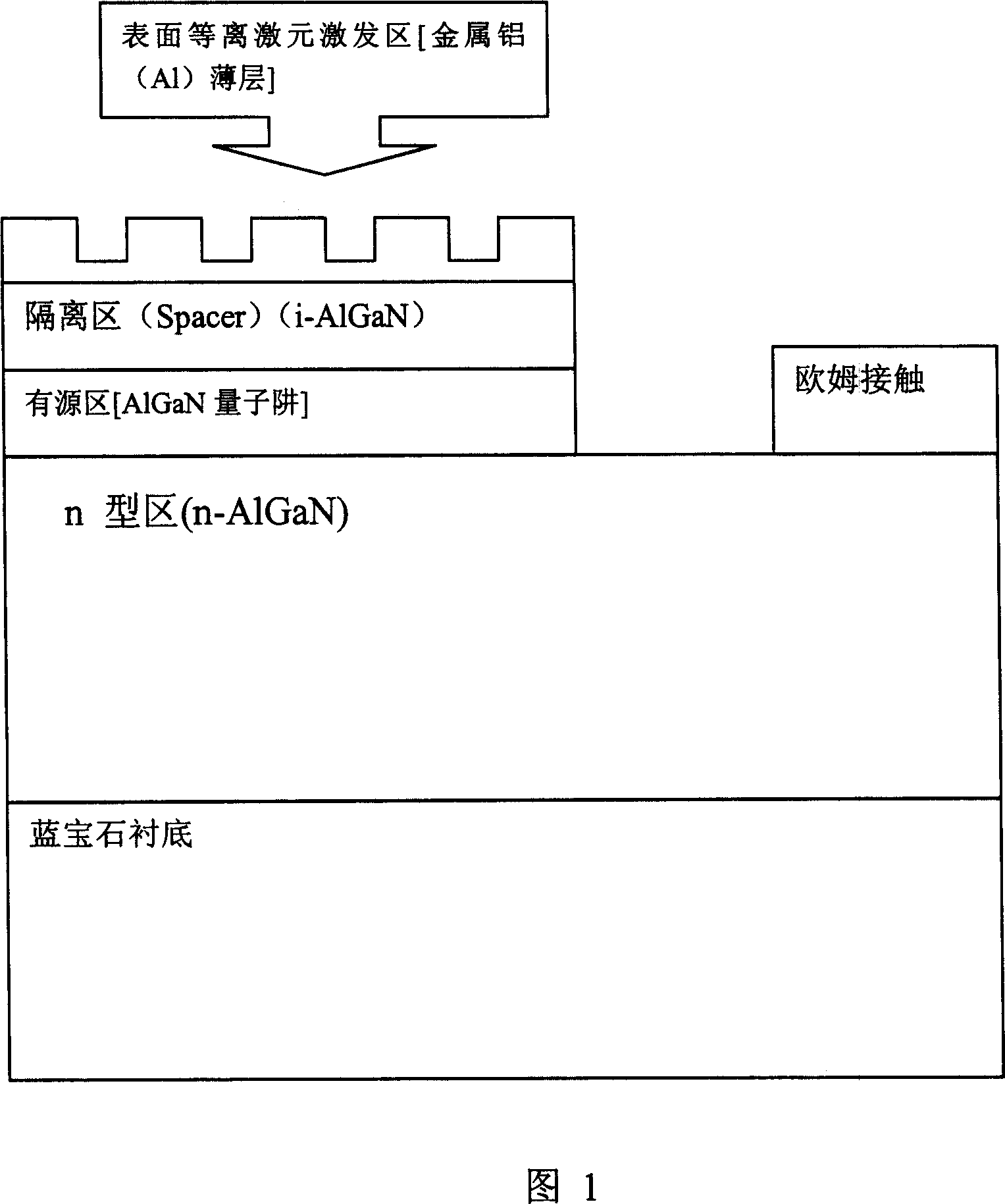

[0038] The specific implementation method of the preparation of the device structure in Figure 1: (taking AlGaN as an example)

[0039] 1) First grow n-type AlGaN several microns thick on the sapphire substrate;

[0040] 2) Then grow the intrinsic quantum well active region on it, (such as Al 0.8 Ga 0.2 N / Al 0.18 Ga 0.82 N multiple quantum wells);

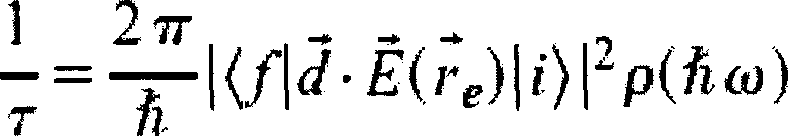

[0041] 3) On the multiple quantum wells, an intrinsic AlGaN isolation layer (spacer) with a thickness of several to tens of nanometers (nm) is grown. Electron recombination coupling to periodic structure electrodes to excite surface plasmons);

[0042] 4) Etching away a part of AlGaN and quantum well until the bottom n-AlGaN is exposed;

[0043] 5) making ohmic contact electrodes on the exposed n-AlGaN surface;

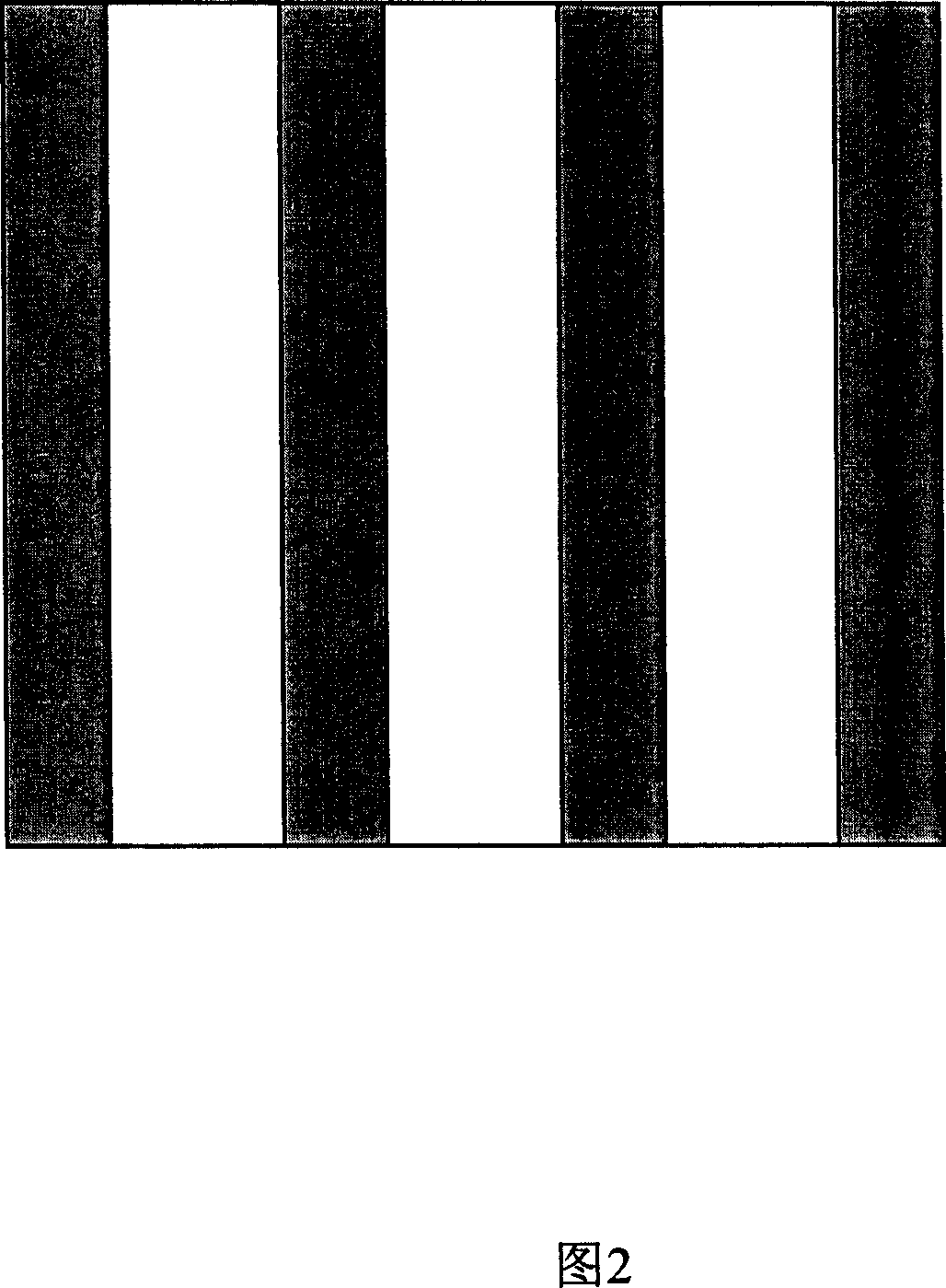

[0044] 6) On the surface of the remaining AlGaN isolation layer, use aluminum (Al) to make a grid-shaped electrode as shown in Figure 2 (it can also be a two-dimensional structure such as a ring, grid, and periodic is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com