Method for making niobic magnesium acid lead-lead titanate single-crystal longitudinal vibration transverter

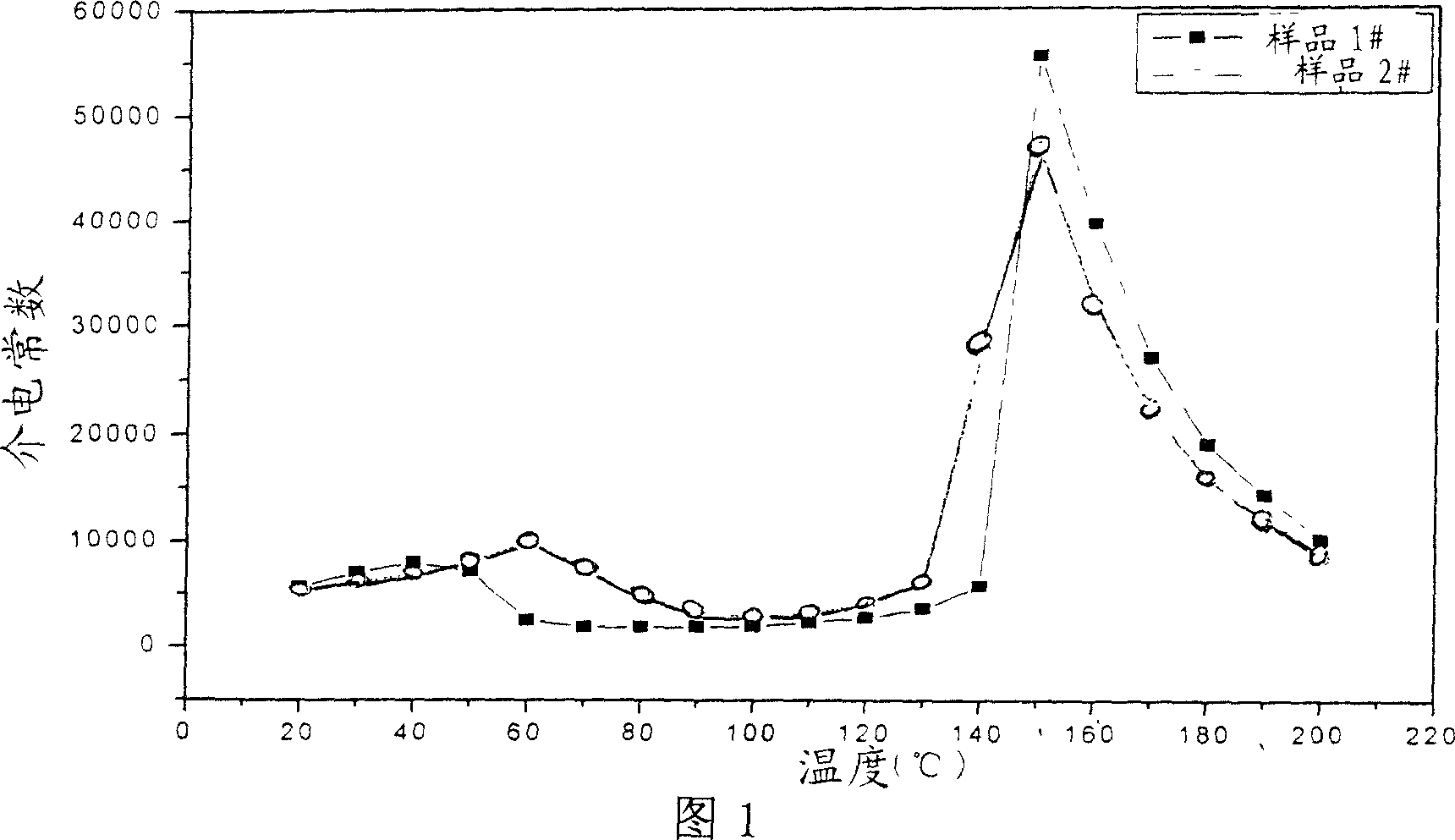

A lead magnesium niobate, transducer technology, applied in piezoelectric devices/electrostrictive devices and other directions, can solve the problems of large changes in PMNT single crystal capacitance, and achieve low production process temperature, simple application method, and high electromechanical coupling. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

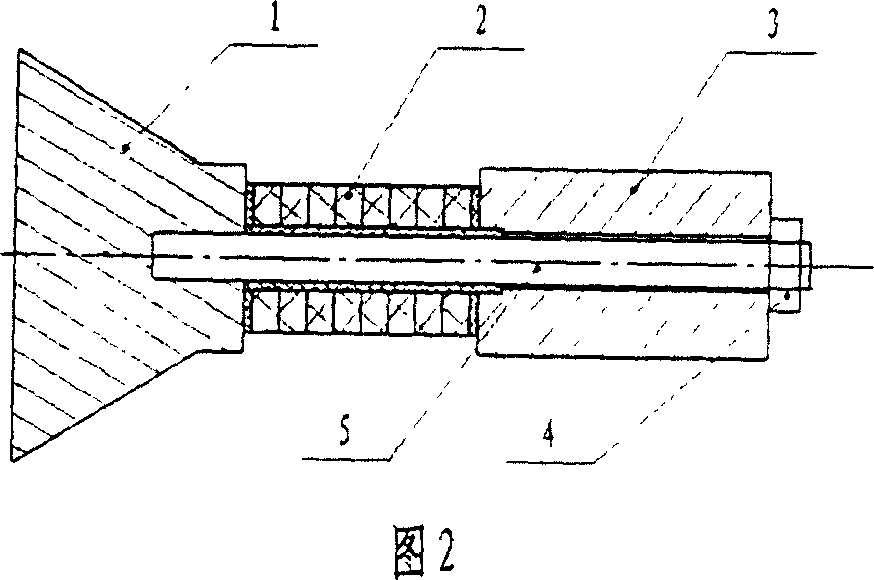

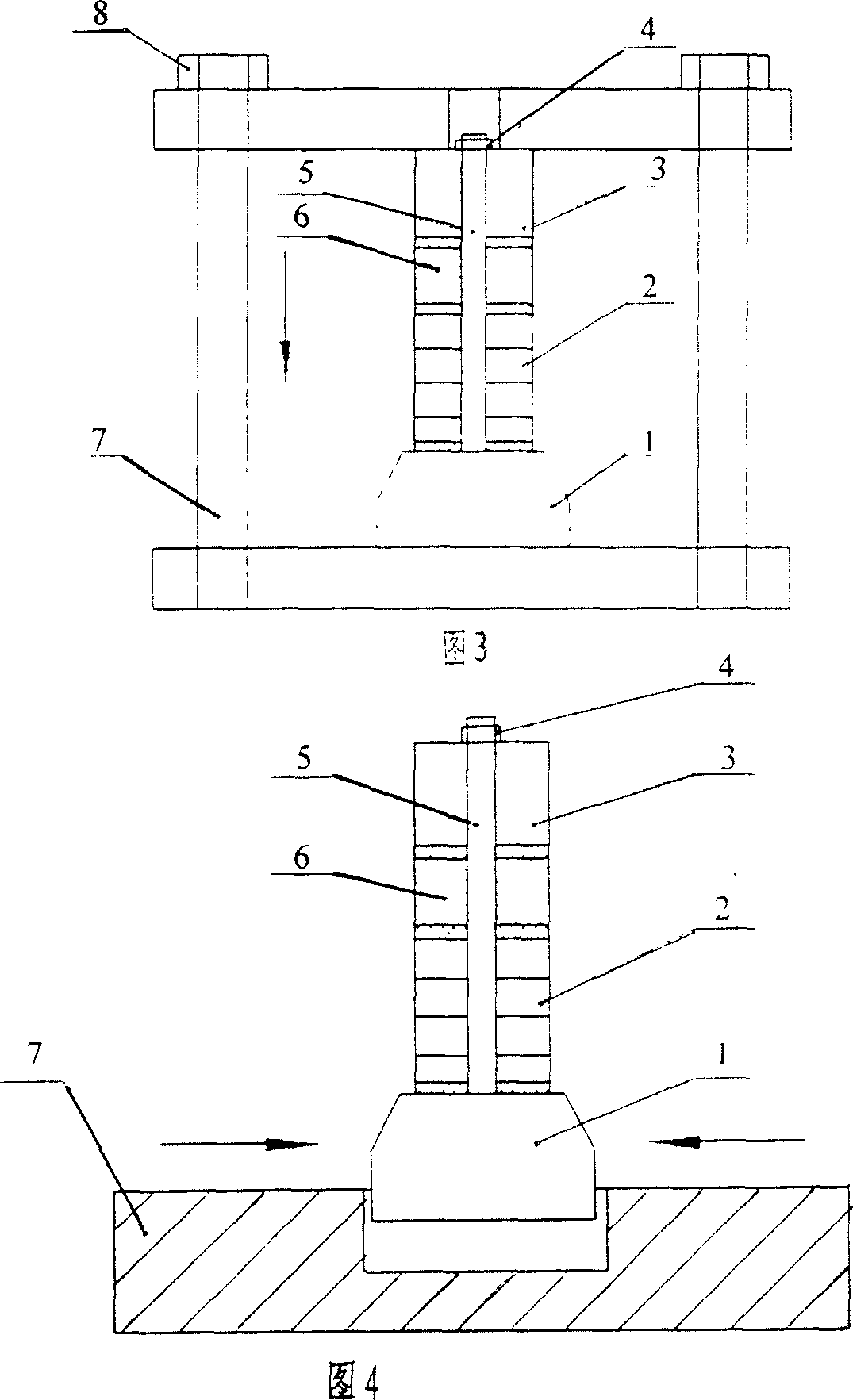

[0036] With reference to the structure of Fig. 2, a PMNT single crystal longitudinal array transducer with a resonant frequency of 11KHz has been produced, according to the prestressing mode of Fig. 4, the method of the present invention is described in detail:

[0037] (1) First, according to the structure of the longitudinal array transducer shown in Figure 2, the Ansys software is used to design the parts of the PMNT single crystal longitudinal vibration transducer with a resonant frequency of 11KHz (mainly including the radiation head 1, the tail load 3 and the The material, size and quantity of the piezoelectric element stack 2) in the middle. Among them, the materials of the front radiation head 1 and the tail load 3 are selected from aluminum and copper respectively, the surface of the front radiation head 1 is designed to be a square 40×40mm, and the tail load 3 is φ20×φ7×32mm, and a common stress screw 5 is used. The diameter is φ7mm. The piezoelectric element stack ...

Embodiment 2

[0042] Embodiment 2: With reference to the structure of Fig. 2, according to the pressurization method shown in Fig. 4 and the steps described in Example 1, a PMNT single crystal transducer with a prestress size of 12.0Mpa is produced, and then carried out at a low temperature of 50°C Cured for 40 hours. The capacitance of the solidified PMNT single crystal transducer measured by a capacitance meter is 16.5nF. Subsequently, the PMNT single crystal transducers were vulcanized with polyurethane rubber at 40 °C for 24 hours to seal them into a single array. The pool test results show that the PMNT single crystal transducer has a maximum emission voltage sensitivity Svmax=147.0dB (corresponding to a frequency of 11KHz), and a maximum receiving voltage response sensitivity of Momax=-172.5dB (corresponding to a frequency of 14KHz). Compared with the PMNT single crystal transducer in Example 1, its emission sensitivity is higher, and its reception sensitivity is slightly lower.

Embodiment 3

[0043] Embodiment 3: With reference to the structure of Fig. 2, according to the pressurization method shown in Fig. 4 and the steps described in Example 1, a PMNT single crystal transducer with a prestress size of 6.0Mpa is produced, and then carried out at a low temperature of 60°C Cured for 70 hours. The PMNT single crystal transducer was vulcanized with rubber at 60°C for 40 hours to seal it into a single array.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com