Coking waste water treatment method of tetravalence manganese compound oxidation, chemical precipitation and biochemical combination

A technology of coking wastewater and chemical precipitation, which is applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, and bio-organic part treatment, etc. It can solve the problems of difficulty in wide application, large consumption of chemicals, materials and energy, and high treatment costs. Achieve the effect of improving biodegradability, low cost, and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

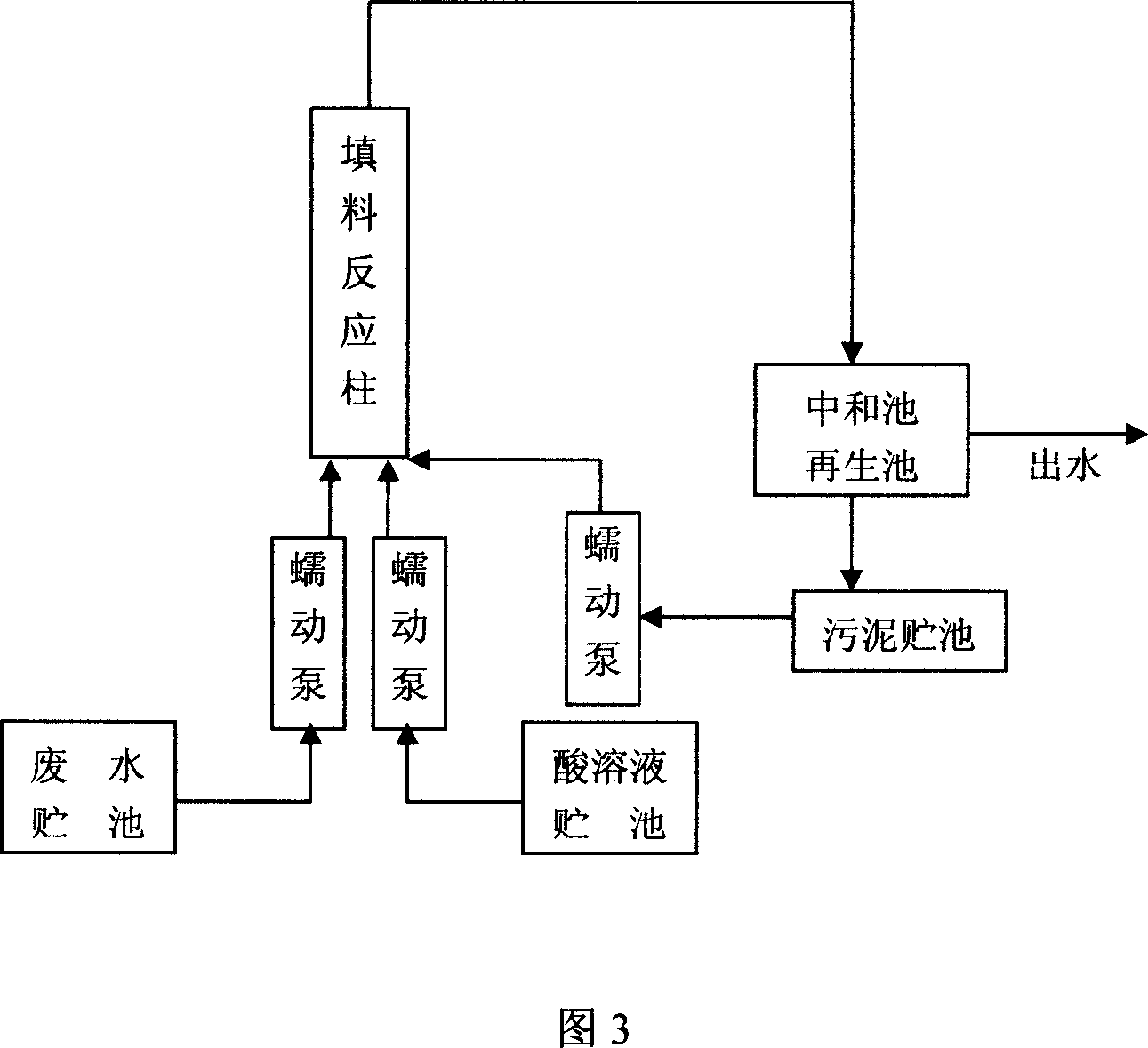

[0046] Taking the coking wastewater from the coking workshop of the iron and steel complex as the object, the concentration of pollutants in it is 1262mg / L of phenols (calculated as phenol), 6821mg / L of COD, and 6821mg / L of NH 4 -N is 4177mg / L, S 2- 64.3mg / L. Wastewater is treated according to the experimental device in Figure 4, the concentration of pollutants in the effluent is regularly measured, and the removal rate of pollutants is calculated.

[0047] The coking wastewater is injected into the oxidation reactor, and excessive natural manganese oxide-pyrolulusite is added to the oxidation reactor.

[0048] Sulfuric acid is added to the oxidation reactor to adjust the pH value of the wastewater to 1.5, and the residence time of the wastewater in the oxidation reactor is 2 hours.

[0049] The water after the oxidation reaction is injected into the neutralization reactor, and magnesite is added to the neutralization reactor to make the pH value of the effluent 9. During t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com