Organism degradable star-type structure poly (glycolide-lactide) medicine carrier microsphere and preparation method thereof

A technology of polyglycolide and drug-carrying microspheres, which is applied in the directions of pharmaceutical formulations and medical preparations with inactive ingredients, can solve the problems of complicated experimental process, etc., so as to improve the poor packaging ability, improve the drug-carrying capacity and the packaging capacity. Buried rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

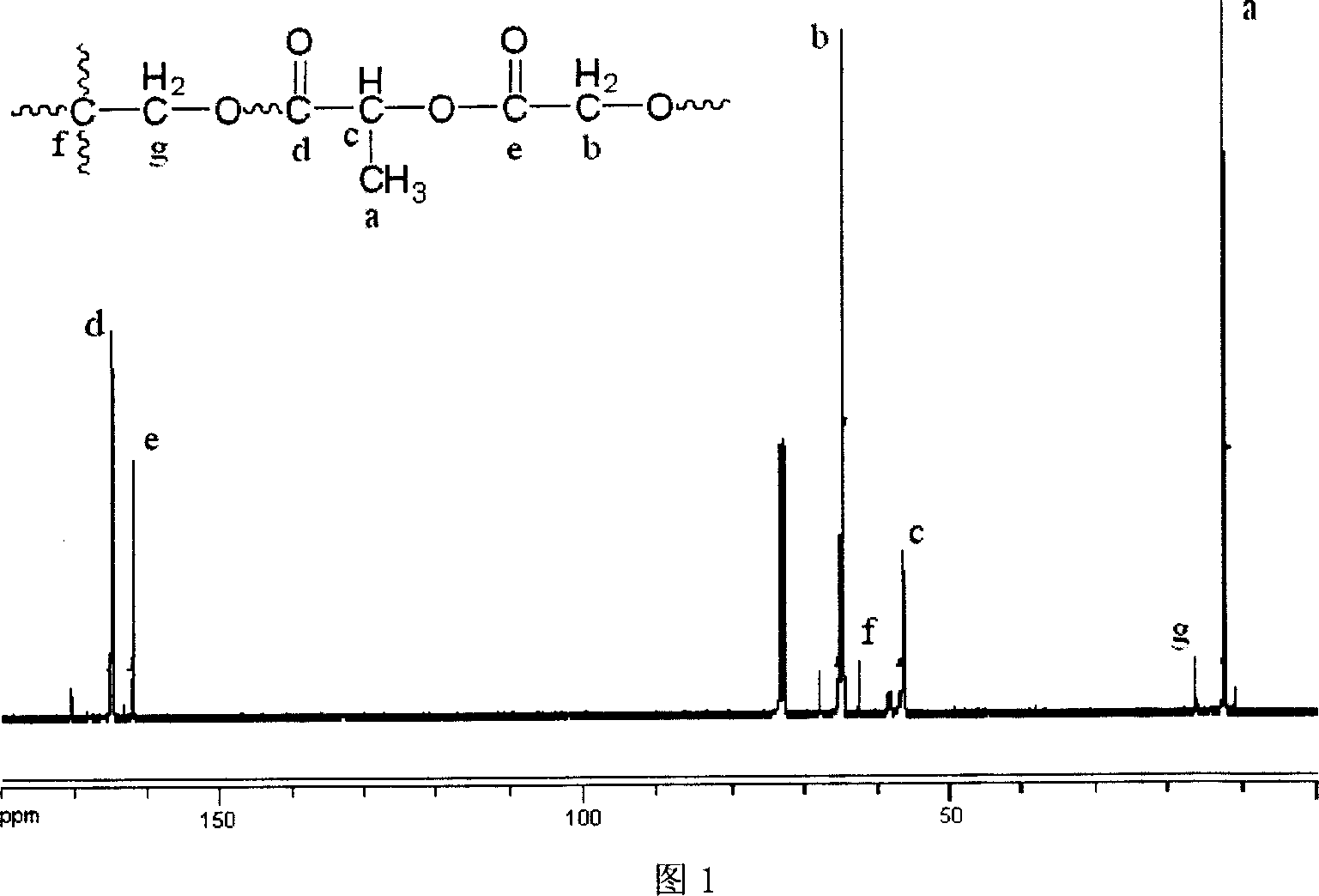

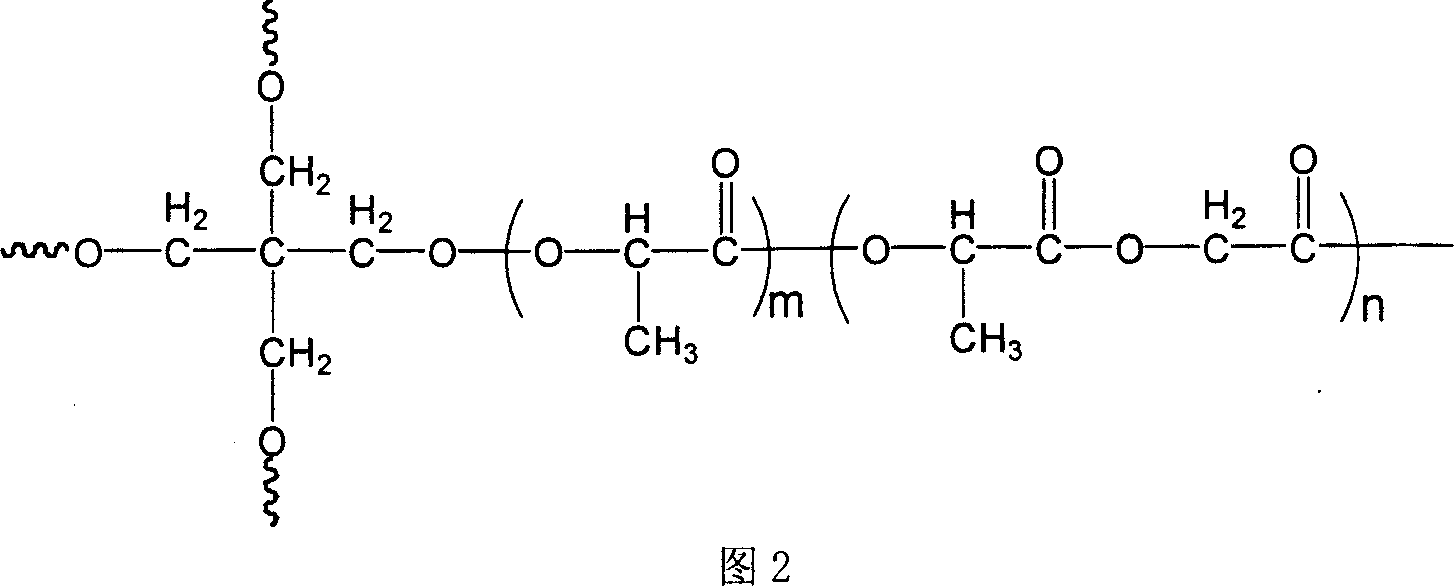

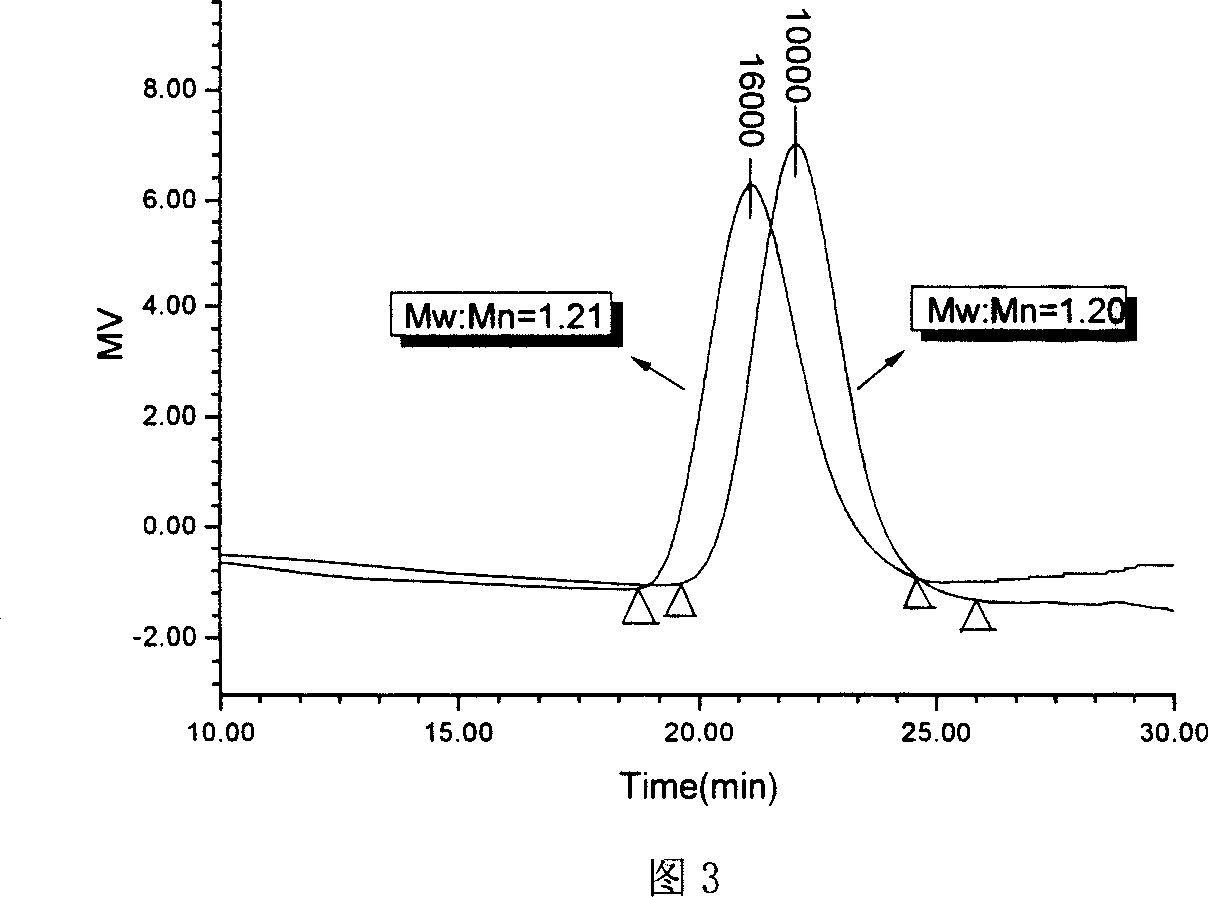

[0023] Example 1: 0.3mol lactide, 0.1mol glycolide, 2×10 -3 mol pentaerythritol and 4×10 -5 mol of stannous isooctanoate was mixed and put into a sealed tube, melted and sealed the nozzle under vacuum condition (30Pa), and reacted at 160°C for 8h. The obtained product was dissolved in dichloromethane and then filtered, anhydrous methanol was added dropwise to precipitate, and the precipitate was vacuum-dried to obtain four-armed star polylactide. Its number average molecular weight was 9000. Its structure consists of 13 C NMR (VARIAN UNITY-plus400) nuclear magnetic spectrum confirmed, Figure 1. In the spectrogram, the peak f (δ=62.25ppm) of the quaternary carbon atom and the peak g (δ=15.71ppm) of the methylene carbon atom in the pentaerythritol molecule can be found respectively, thus proving the star structure of the polymer.

Embodiment 2

[0024] Example 2: 70 mg of bovine serum albumin (molecular weight: 67,000) was dissolved in 0.3 mL of an aqueous solution of 0.05% (w / v) polyvinyl alcohol (17-88, Beijing Organic Chemical Factory) to form an internal water phase. Dissolve 0.6 g of four-armed star polylactide in 12 mL of dichloromethane to form a medium oil phase. Under the condition of heating at 60°C, mix the inner water phase and the middle oil phase, and mix evenly under ultrasonic (Sonics & Materials VCX, 400W, 30s) to form W / O colostrum. 250 mL of 0.2% (w / v) polyvinyl alcohol aqueous solution was used as the external aqueous phase. Inject W / O colostrum into the external water phase under high-speed stirring, emulsify to form a W / O / W emulsion, stir until all the dichloromethane volatilizes, and solidify into balls; centrifuge and collect the obtained microspheres, and After freeze-drying, the drug-loaded microspheres of biodegradable star polylactide can be obtained. The drug loading amount is 37.85μg / mg...

Embodiment 3

[0025] Example 3: The operation steps of this example are the same as those of Example 2, except that the amount of star polylactide used is 0.8 g, and the drug loading of the obtained drug-loaded microspheres is 31.18 μg / mg microspheres, the embedding rate was 33.41%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Drug loading | aaaaa | aaaaa |

| Drug loading | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com