Hexagonal nanometer boron nitride microsphere and its synthesis process and application

A technology of hexagonal boron nitride and boron nitride microspheres, applied in chemical instruments and methods, boron compounds, inorganic chemistry and other directions, can solve the problems of uncontrollable microscopic morphology, complex synthesis process and high cost, and achieves simple and High purity, no jamming load improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1. Follow the reaction equation:

[0040]

[0041] Weigh the raw materials according to the molar ratio of boron oxide and monohydric alcohol as 1:3, and slowly add boron oxide to the monohydric alcohol in fractions under stirring (methanol is the best monohydric alcohol, followed by ethanol, propanol, etc. If the carbon content is too high, it is easy to generate amorphous carbon in the follow-up nitriding reaction and make the product impurities too much. The following are all represented by methanol), until boron oxide is completely reacted with methanol to obtain a clear solution;

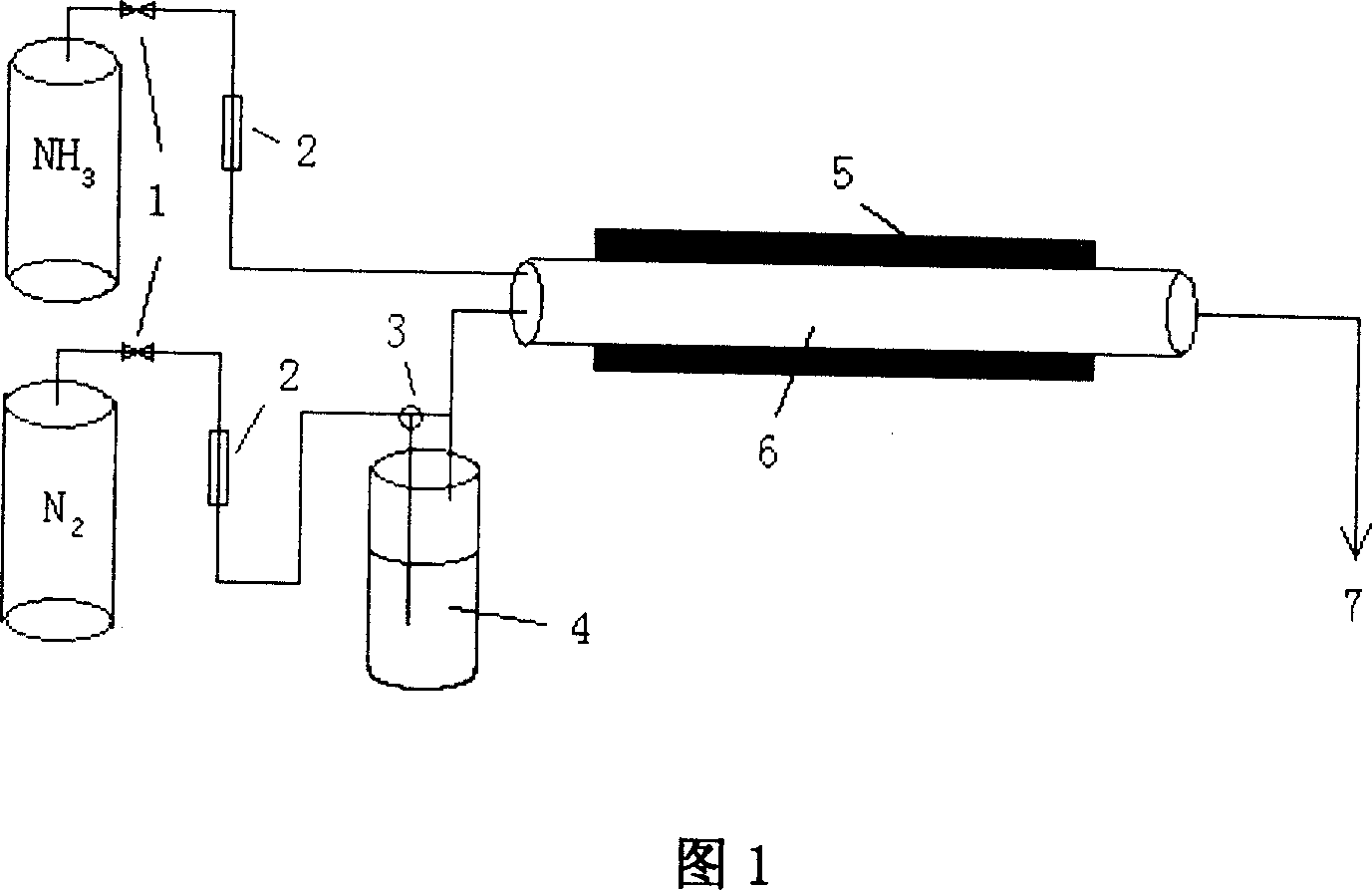

[0042] Step 2. Connect the synthesis device as shown in Figure 1. Tube furnaces use corundum tubes. Under the condition of ensuring airtightness, turn the switch to the point where the nitrogen gas only leads to the raw material container, and the air in the container is exhausted, and the amount of nitrogen passing through is 5 times the volume of the air in the container; ...

Embodiment 2

[0046] Step 1. Follow the reaction equation:

[0047]

[0048] Weigh the raw materials according to the molar ratio of boron oxide and monohydric alcohol as 1:3, and slowly add boron oxide to methanol several times under stirring until the boron oxide completely reacts with methanol to obtain a clear solution;

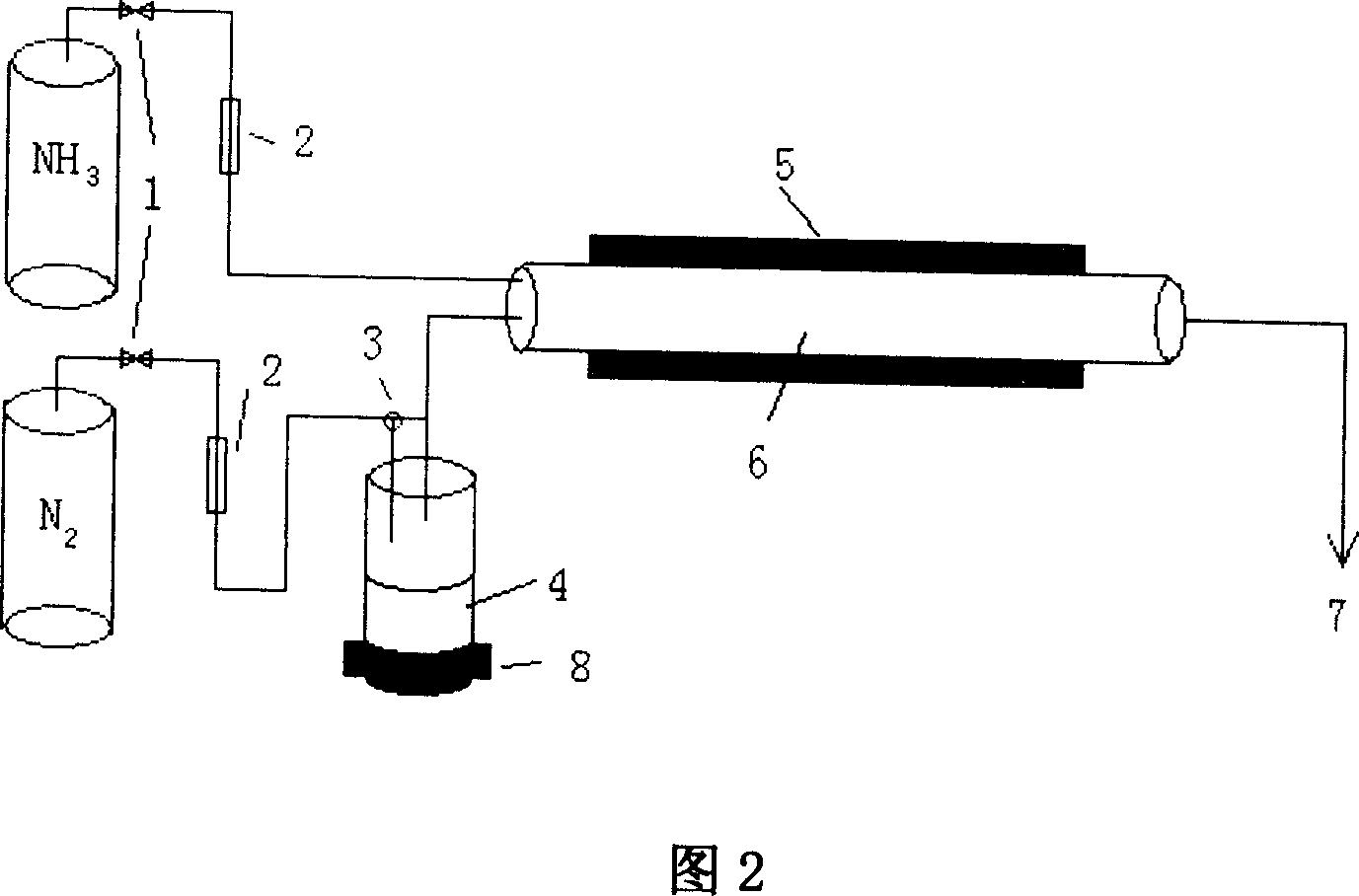

[0049] Step 2. Connect the synthesis device as shown in Figure 2. The tube furnace uses a corundum tube. Under the condition of ensuring airtightness, turn the three-way switch so that the nitrogen gas only leads to the raw material container, and the air in the container is exhausted. , the volume of the nitrogen gas is 5 times the volume of the air in the container; then the three-way switch tube is screwed so that the nitrogen gas only leads to the reactor, and the air is exhausted, and the volume of the nitrogen gas is 5 times the volume of the reaction container. ;Continue to pass a small amount of nitrogen, so that the tube furnace is under the protection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com