Laser-electric arc composite processing method

A composite processing and arc technology, applied in arc welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as insufficient thermal electron emission, light beam absorption, scattering, etc., achieve large industrial application potential and development prospects, and ensure full Utilize and increase the effect of penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

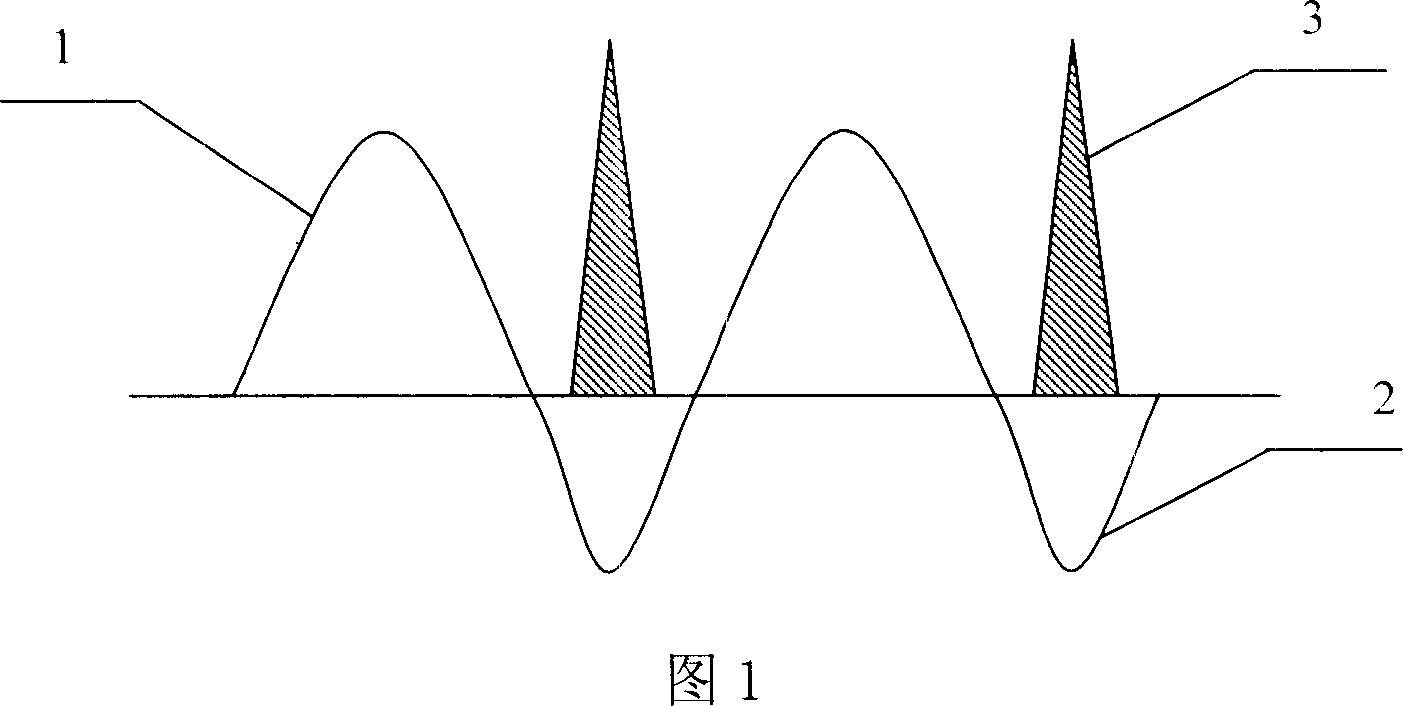

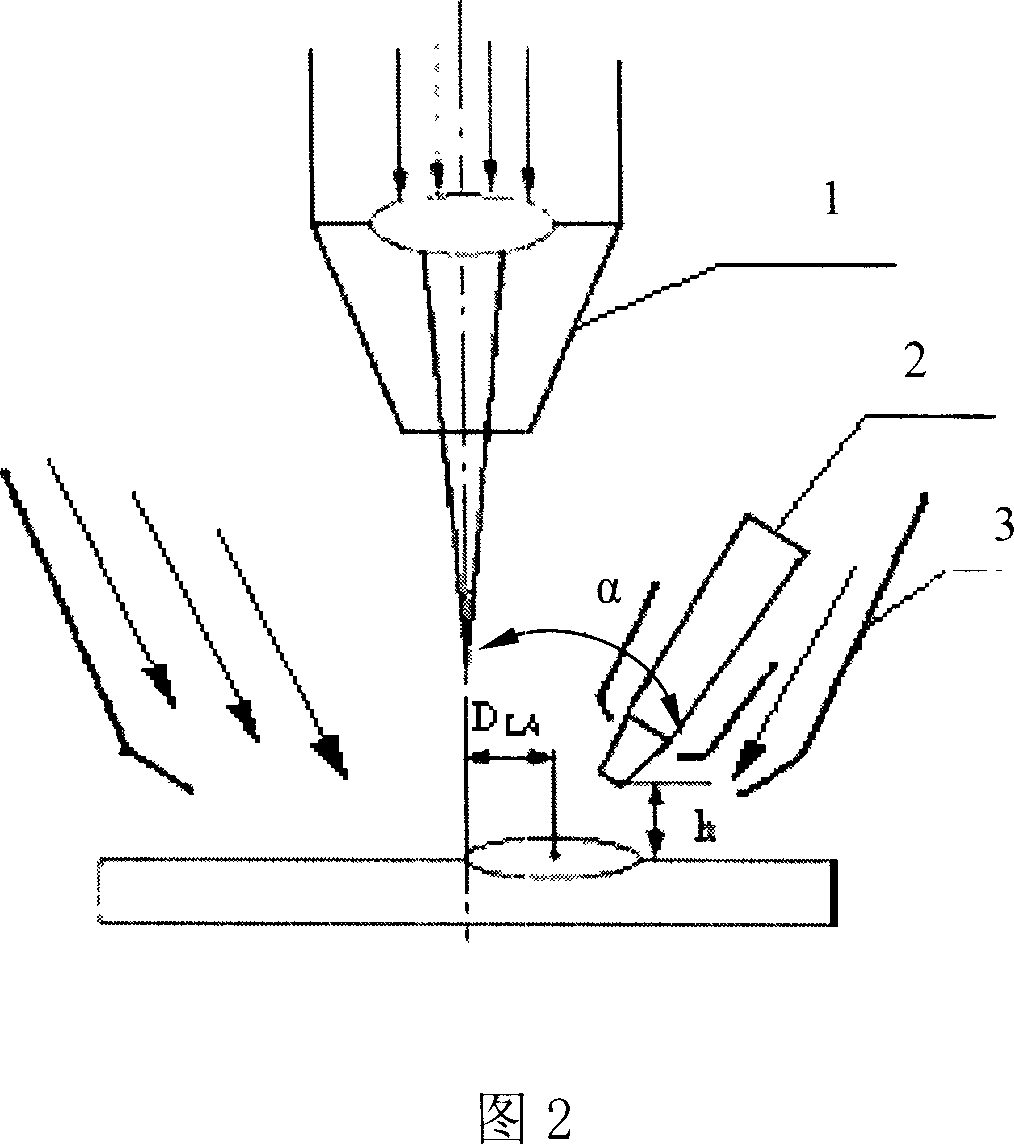

[0010] This embodiment adopts a paraxial laser-arc compound heat source device, refer to the relative position shown in FIG. 2 . The angle α between the laser beam 1 and the arc electrode 2 is 45°; the distance between the impact point of the laser beam 1 and the center of the welding pool of the arc electrode 2 is D LA is 2mm; the distance h from the tip of the electrode 2 in the protective gas cover 3 to the workpiece is 2mm. Then determine the laser power, arc power, and shielding gas flow according to the material to be processed and the thickness of the plate. In the hybrid welding process, the laser is in the pulse output mode, and the arc is in the AC mode. Set the trigger pulse signal, according to the needs of welding, cutting, and surface treatment, make the peak value of the laser pulse act on the negative half-wave interval of the AC arc, and the frequency of the laser pulse is consistent with the frequency of the current. Refer to Figure 1, where welding magnesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com