Semiconductor structure and mfg. method thereof

A manufacturing method, semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as damage to thin films, reduced efficiency of Ti absorbing oxygen atoms, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

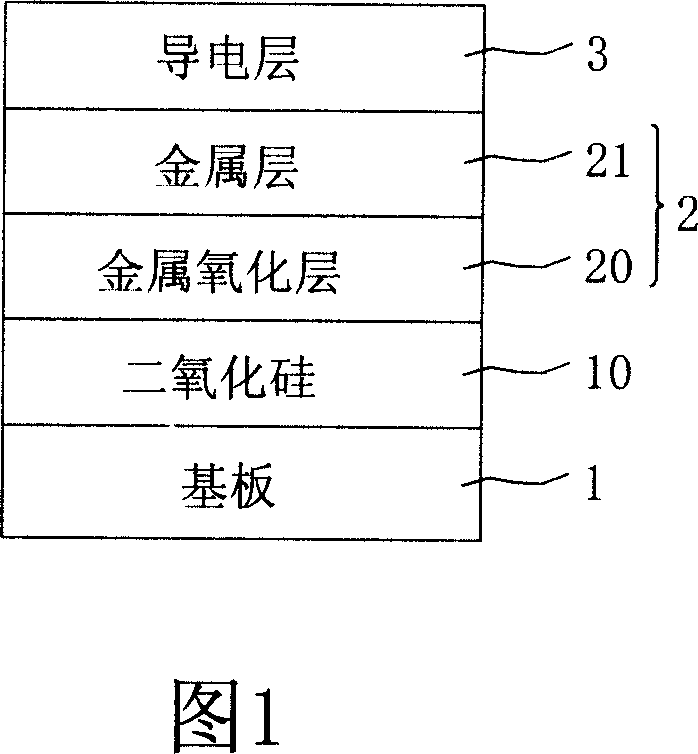

[0041] Please refer to FIG. 1 , which is a schematic cross-sectional view of the first embodiment of the semiconductor structure of the present invention. It can be seen from the figure that the first embodiment of the present invention provides a semiconductor structure, including: a substrate 1 , a dielectric layer unit 2 and a conductive layer 3 .

[0042] Wherein, the substrate 1 can be a silicon substrate (Si substrate), and silicon dioxide 10 (SiO2) is formed on the silicon substrate. 2 ). The dielectric layer unit 2 is formed on the substrate 1, and the dielectric layer unit 2 at least includes a metal oxide layer 20 and a metal layer 21, and the metal oxide layer 20 and the metal layer 21 are formed by stacking each other. The conductive layer 3 is disposed on the dielectric layer unit 2 , and the conductive layer 3 can be titanium nitride (TiN).

[0043] In addition, the metal oxide layer 20 can be hafnium dioxide (HfO 2 ), hafnium oxysilicide (HfSiO), hafnium sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com