Process for synthesizing heat-radiating ointment

A technology of heat dissipation paste and mixture, which is applied in the field of preparation of thermal interface materials, and can solve problems such as low efficiency, inability to disperse heat conduction powder uniformly, and long time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

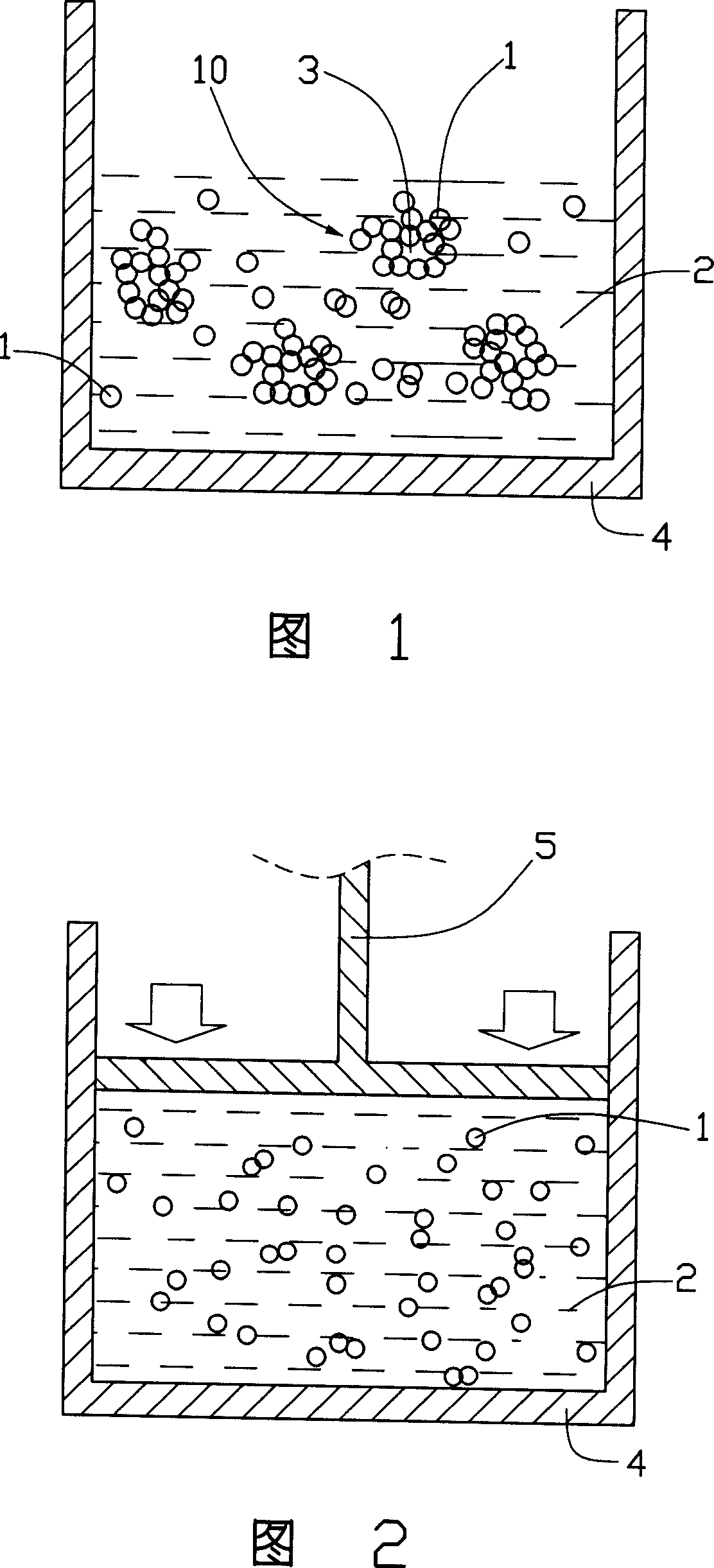

[0011] The method for synthesizing heat dissipation paste will be further described in detail with reference to the accompanying drawings and examples.

[0012] The method for synthesizing thermal paste comprises the steps:

[0013] Step 1, providing filling powder and thermal paste base material. The filler powder is a thermally conductive material, including one of silver, gold, copper, nickel, aluminum, aluminum oxide, zinc oxide, boron nitride, bauxite, aluminum nitride, graphite, carbon black or a combination thereof.

[0014] The mass ratio of the filler powder to the base material is 1:1-9:1.

[0015] The base material can be liquid silicone oil, polyethylene glycol, polyester or a combination thereof at normal temperature; or polyvinyl acetate, polyethylene, siloxane, polyvinyl chloride, amino ring Oxygen resin, polyacrylate, polypropylene, epoxy resin, polyoxymethylene, polyacetal, polyvinyl alcohol or a combination thereof.

[0016] Step 2, adding the filling powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com