Spray drying method for water-soluble iron chelate of glycine

A technology for chelating iron with glycine and drying method, which is applied in the fields of iron organic compounds, food science, food preparation, etc., can solve the problems of large product particles that need to be pulverized, inconvenient for continuous production, long drying cycle, etc., and achieves low processing cost, The effect of enhancing human immune function and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

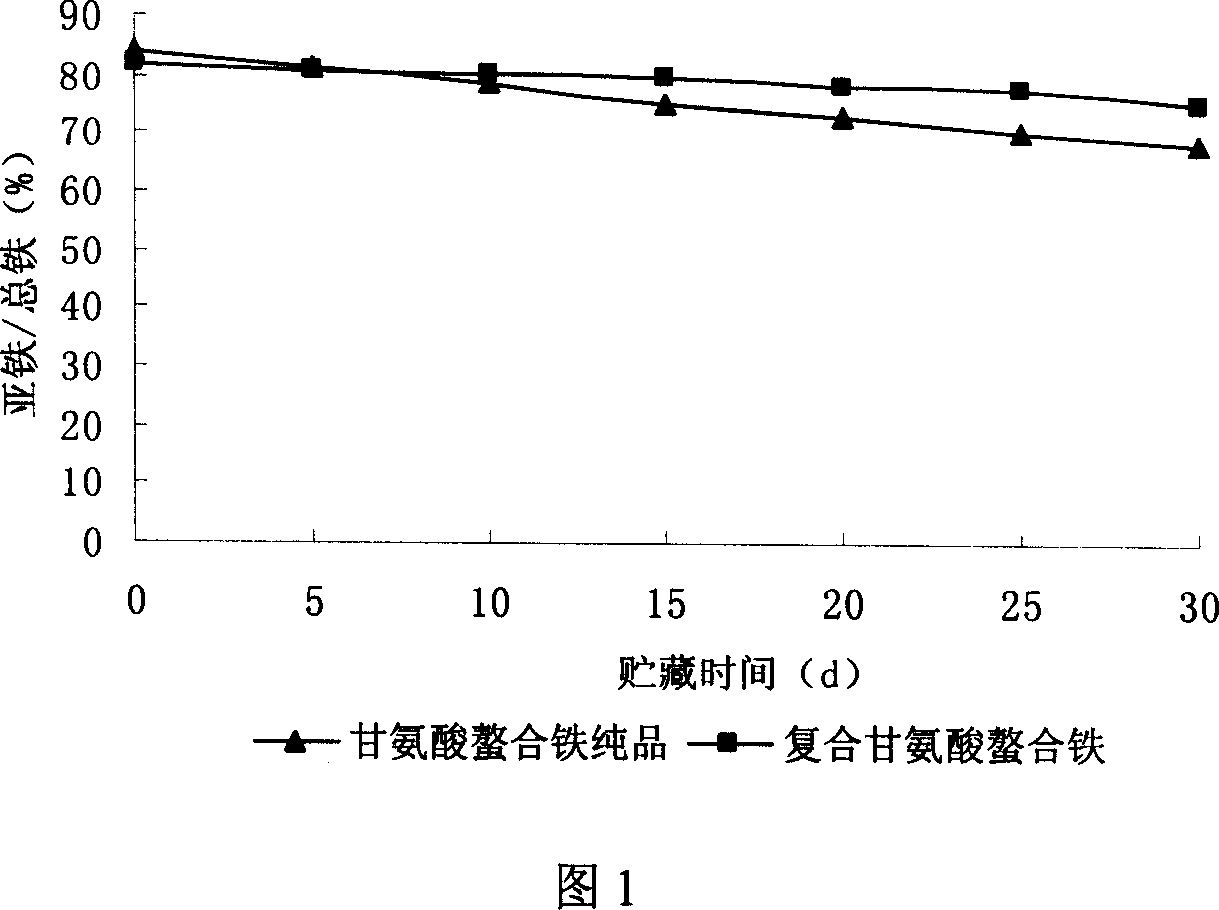

[0032] Weigh 50g water-soluble glycine chelated iron, dissolve in 500mL deionized water, add 50g maltodextrin, 0.65g antioxidant, 0.5g anti-caking agent, solid content is 20%, homogenization pressure 20MPa, homogenization two Second, the inlet air temperature is 180°C, the outlet air temperature is 80°C-90°C, and spray-dried in a spray drying tower.

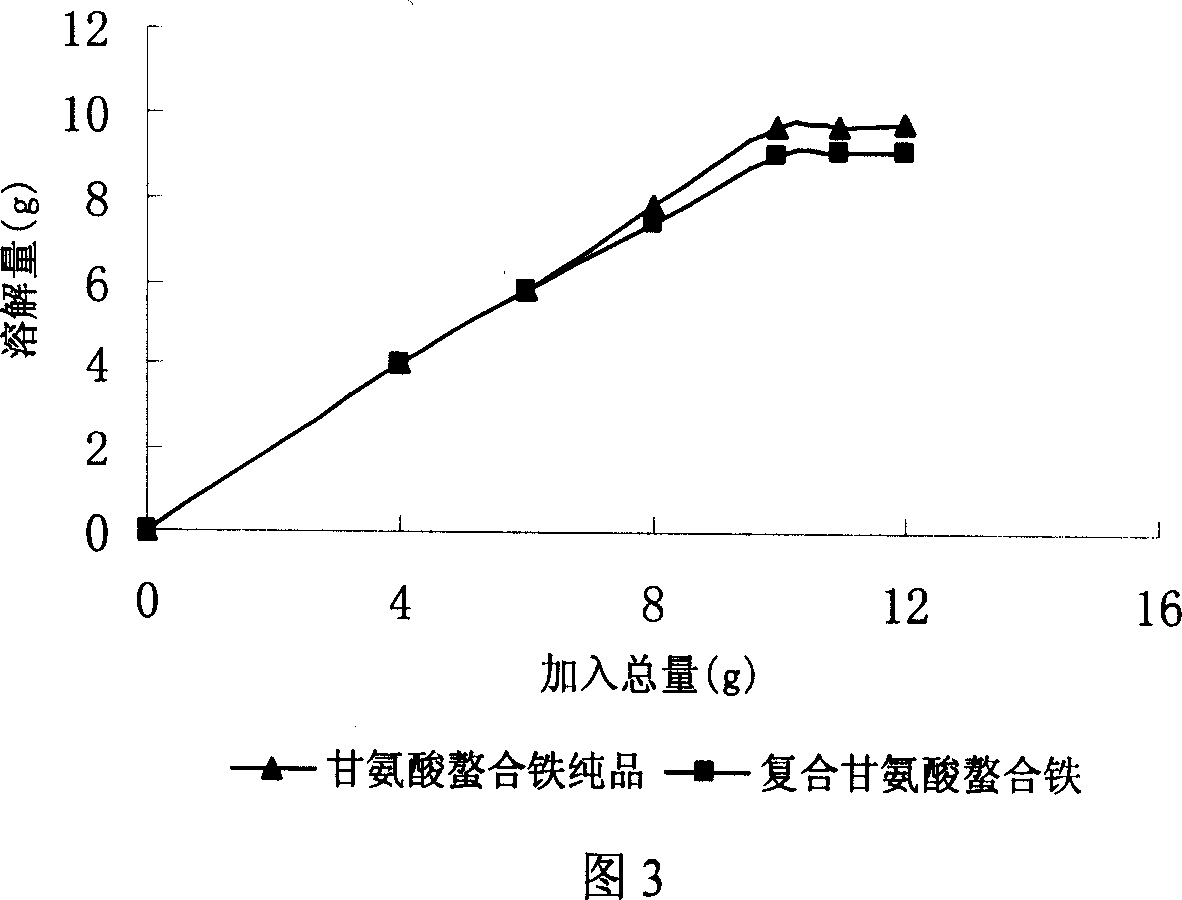

[0033] Take 5g of the product and dissolve it in 100ml of ultra-pure water, the system is transparent without precipitation, the content of ferrous iron accounts for 81.77% of the total iron content, the product is relatively dry and has good solubility.

Embodiment 2

[0035]Weigh 50g of water-soluble glycine chelated iron, dissolve it in 1000mL deionized water, add 50g of maltodextrin, 0.625g of antioxidant, 0.5g of anti-caking agent, the solid content is 10%, the homogenization pressure is 20MPa, and the homogenization pressure is 20MPa. The second time, the inlet air temperature is 180°C, the outlet air temperature is 80°C-90°C, and it is spray-dried in a spray drying tower.

[0036] Take 5g of the product and dissolve it in 100ml of ultrapure water, the system is transparent without precipitation, the content of ferrous iron accounts for 79.10% of the total iron content, the product is dry and has good solubility.

Embodiment 3

[0038] Weigh 50g of water-soluble glycine chelated iron, dissolve in 500mL deionized water, add 50g of maltodextrin, 0.625g of antioxidant, 0.5g of anti-caking agent, the solid content is 20%, the homogenization pressure is 20MPa, and the homogenization pressure is 20MPa. The second time, the air inlet temperature is 160°C, the outlet air temperature is 80°C-90°C, and it is spray-dried in a spray drying tower.

[0039] Take 5g of the product and dissolve it in 100ml of ultra-pure water. The system is transparent without precipitation. The content of ferrous iron accounts for 84.12% of the total iron content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com