Nm-class calcium carbonate carbonization process

A technology of nano-calcium carbonate and process method, which is applied in the field of nano-powder preparation, can solve the problems of large investment in equipment, no discovery of nano-calcium carbonate, poor control of inclusion particles, etc., and achieve the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

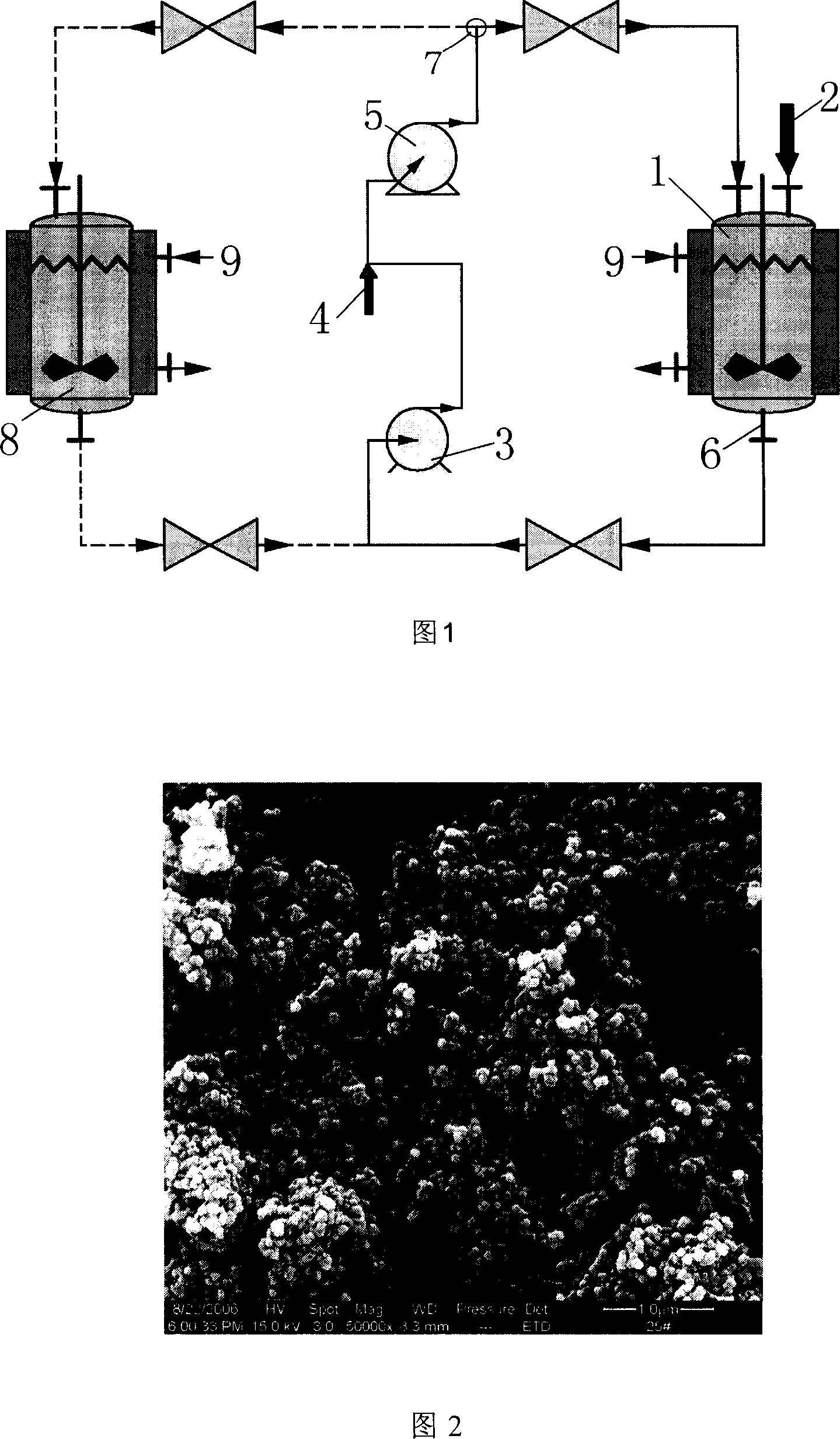

Embodiment 1

[0043] Lime is digested with hot water at 85°C, aged for 8 hours, and the gray-to-water ratio is 1:4. The concentration of carbon dioxide in the mixed gas is 30%; the density of calcium hydroxide suspension is 1.055g / cm 3 , The concentration is 9.6%, and the sedimentation volume is 3.35ml / g. The additive citric acid is chemically pure, and the weight percentage of the citric acid before carbonization is 0.42%. Using a new process of cyclic and strong shear mixed carbonization, the reaction time of the entire carbonization process lasts for 31 minutes, the initial temperature is 18°C, and the reaction end point is 33.5°C; when the pH value of the suspension drops to 7, the reaction stops and the slurry settles The volume is 5.84ml / g, filtered and dried, the particle size of the nano-calcium carbonate product is between 60-85nm, the crystal morphology is a regular cubic structure, and the specific surface area of the nano-calcium carbonate is 34.32m 2 / g (Figure 2).

Embodiment 2

[0045] Lime is digested with hot water at 85°C, aged for 15 hours, and the gray-to-water ratio is 1:4. The concentration of carbon dioxide in the mixed gas is 30%; the density of calcium hydroxide suspension is 1.055g / cm3, the concentration is 9.6%, and the sedimentation volume is 3.35ml / g. The additive citric acid is chemically pure, and the weight percentage of the citric acid before carbonization is 1.68%. The new carbonization process of circulation and strong shearing is adopted. The reaction time of the whole carbonization process lasts for 32 minutes, the initial temperature is 18°C, and the reaction end temperature is 34°C; when the pH value of the suspension drops to 7, the reaction is stopped, and the slurry is stable. The sedimentation volume is 3.54ml / g, filtered and dried, the particle size of the nano-calcium carbonate product is between (50-60)×330nm, the crystal morphology is a chain structure, and the specific surface area of the nano-calcium carbonate is 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com