Method for measuring reflectance ratio of high reflected mirror

A measurement method and technology of reflectivity, which is applied in the field of measurement of high mirror reflectivity, can solve the problems of limited measurement accuracy, signal-to-noise ratio decrease, measurement accuracy limitation, etc., and achieve simplified measurement device, large signal amplitude and simple device Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

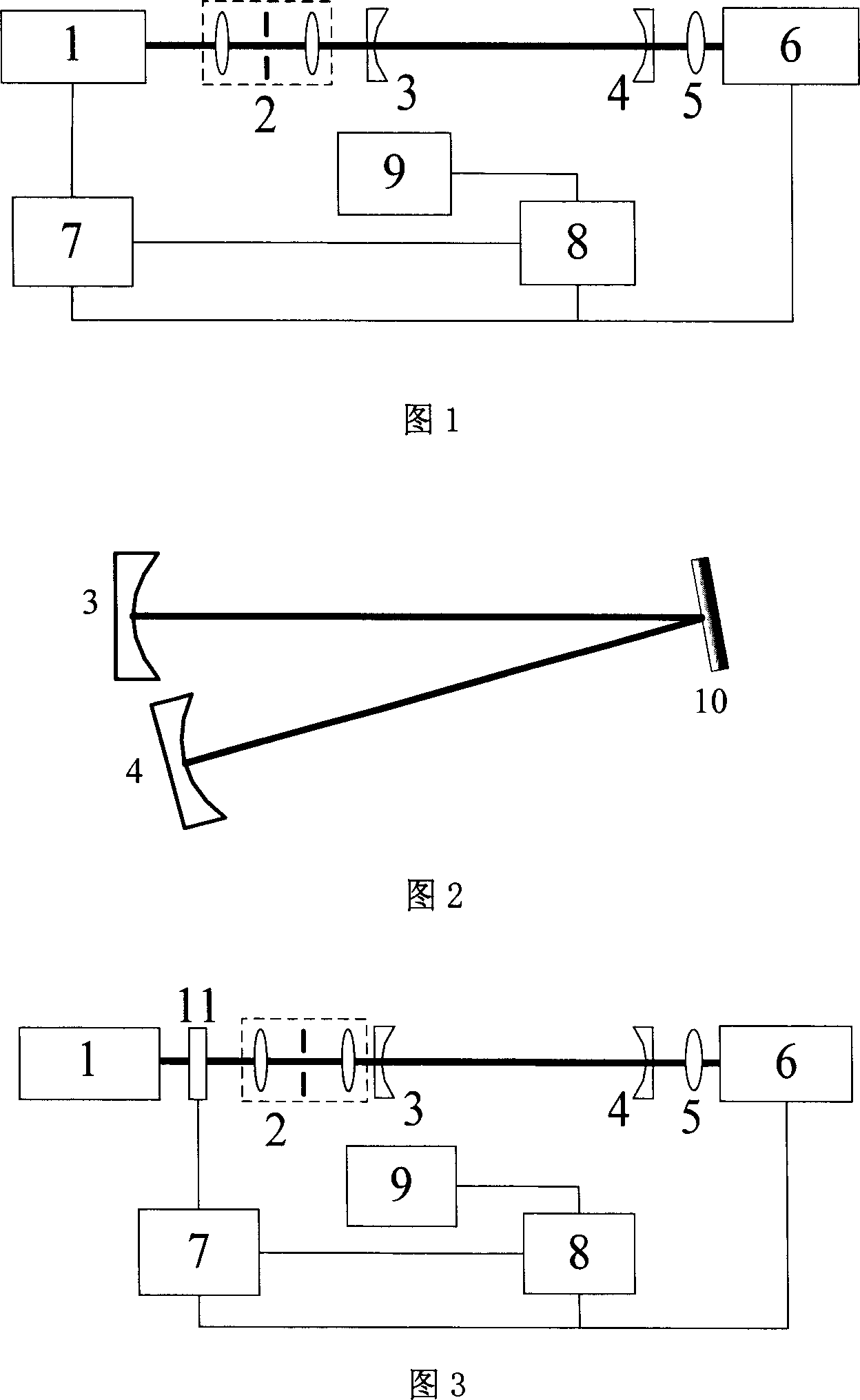

[0025] As shown in Figure 1, measuring device of the present invention is made of light source 1, spatial filtering and telescopic system 2, plano-concave high reflection mirror 3,4, converging lens 5, detector 6, trigger switch circuit 7, oscilloscope 8 and computer 9 composition. The thick line in the figure indicates the optical path, and the thin line indicates the connection of the signal line. Wherein the detector 6 generally adopts a photodiode detector.

[0026] The light source 1 adopts a wide-spectrum continuous semiconductor laser, and its spectral width is between 0.001nm and 50nm, so that the laser spectrum covers multiple optical cavity eigenmodes. The spatial filtering and telescopic system 2 consists of two lenses and a pinhole, and is used to shape the laser beam output by the light source 1 into a fundamental mode and match it with the optical cavity mode. Two identical flat-concave high-reflection mirrors 3 and 4 are coated with a high-reflection film on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com