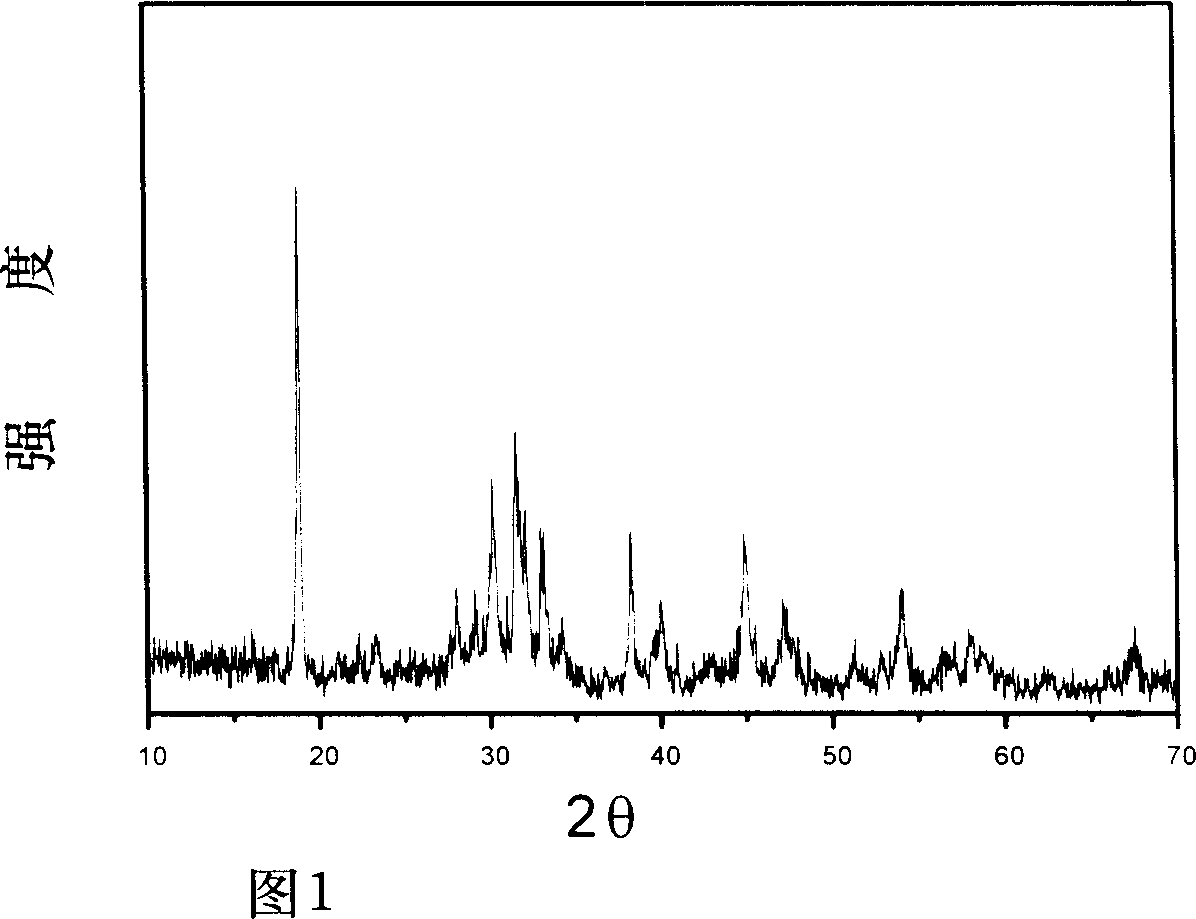

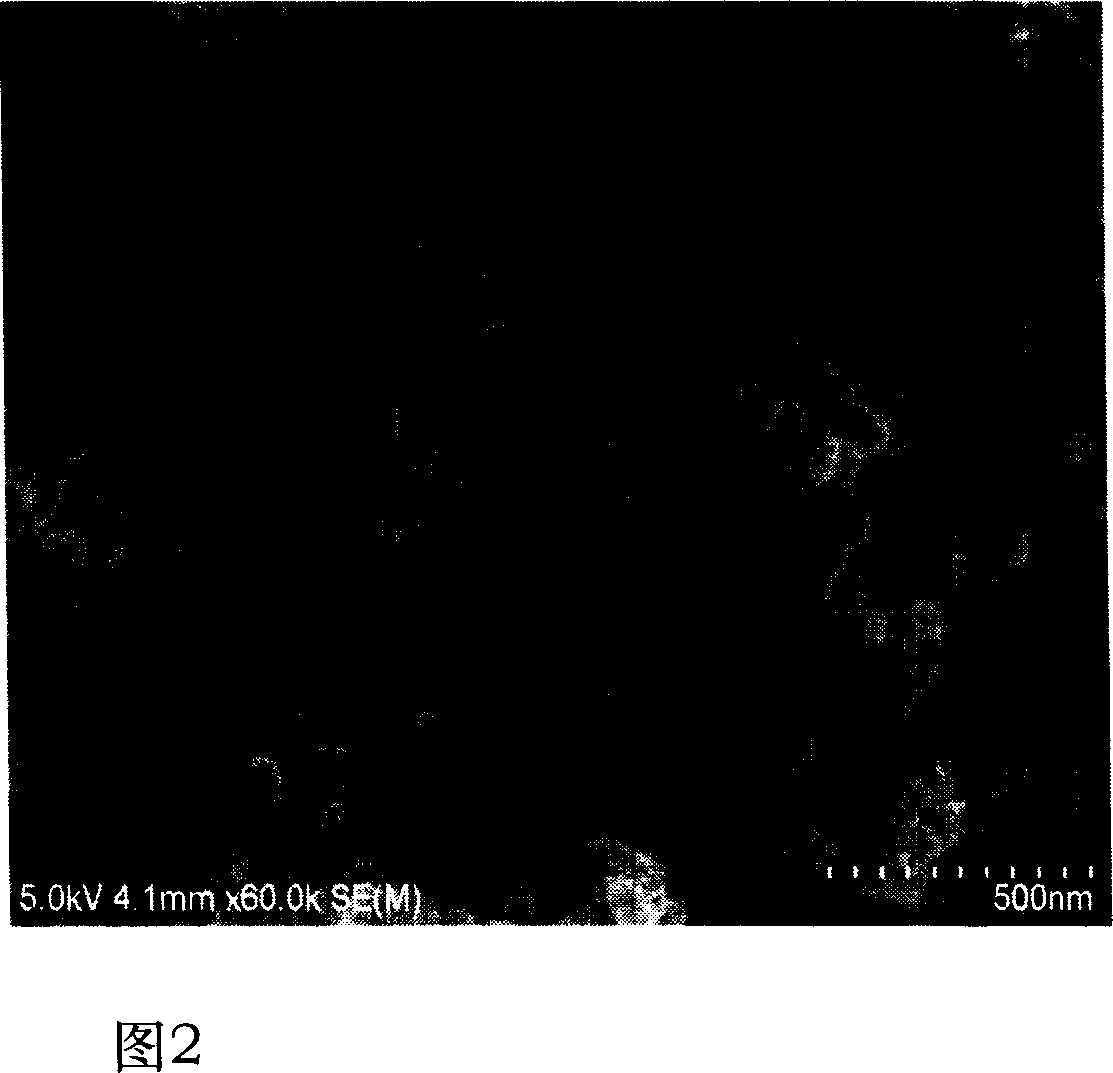

Method for preparing nano BaLn2Ti3O10 heat-barrier coating ceramic layer material

A technology for thermal barrier coatings and ceramic layers, which is applied in the field of preparing nano-BaLn2Ti3O10 thermal barrier coating ceramic layer materials, can solve the problems of affecting the service life of coatings and reducing the thermal shock performance of coatings, and achieve low density, high strength and Hardness, Effect of High Thermal Expansion Coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: take barium nitrate, titanium nitrate and lanthanum nitrate as raw material

[0034] The first step: take barium nitrate, titanium nitrate and lanthanum nitrate in a molar ratio of 1:3:2, and dissolve them in deionized water to form a 6mol / L nitrate solution (calculated in terms of total metal ions);

[0035] Second step: adding citric acid in the above-mentioned nitrate solution as a complexing agent to form a citric acid complex solution, the mol ratio of the citric acid to the metal ion in the nitrate solution is 1.3:1;

[0036] The third step: adding polyethylene glycol (molecular weight 4000) to the citric acid complex as a crosslinking agent to obtain a sol precursor, adding 1g of polyethylene glycol in every 100ml of the citric acid complex;

[0037] Step 4: Stir the above sol precursor at room temperature for about 20 minutes to make it a transparent sol;

[0038] Step 5: Evaporate the solvent at 80°C for 150 minutes to obtain a viscous gel, then ...

Embodiment 2

[0041] Embodiment 2: take barium nitrate, titanium nitrate and samarium nitrate as raw material

[0042] The first step: take barium nitrate, titanium nitrate and samarium nitrate in a molar ratio of 1:3:2, dissolve them in deionized water to form a nitrate solution of about 8mol / L (calculated based on the total amount of metal ions);

[0043] Second step: adding citric acid in the above-mentioned nitrate solution as a complexing agent to form a citric acid complex solution, the mol ratio of the citric acid to the metal ion in the nitrate solution is 2:1;

[0044] The third step: add polyethylene glycol (molecular weight 20000) as cross-linking agent, add 0.5g polyethylene glycol per 100ml solution;

[0045] Step 4: Stir the above solution at room temperature for about 30 minutes to make it a transparent sol;

[0046] Step 5: Evaporate the solvent at 70°C for 180 minutes to obtain a viscous gel, then heat the gel at 100°C for 240 minutes to obtain a dry gel;

[0047] Step 6:...

Embodiment 3

[0048] Embodiment 3: take barium nitrate, titanium nitrate and neodymium nitrate as raw material

[0049] Step 1: Take barium nitrate, titanium nitrate and neodymium nitrate in a molar ratio of 1:3:2, and dissolve them in deionized water to form a nitrate solution of about 3 mol / L (calculated based on the total amount of metal ions);

[0050] Second step: adding citric acid in the above-mentioned nitrate solution as a complexing agent to form a citric acid complex solution, the mol ratio of the citric acid to the metal ion in the nitrate solution is 1.5:1;

[0051] The third step: adding polyethylene glycol (molecular weight 4000) to the above-mentioned citric acid complex solution as a crosslinking agent to form a sol precursor, adding 0.8g polyethylene glycol to every 100ml solution;

[0052] Step 4: Stir the above solution at room temperature for about 15 minutes to make it a transparent sol;

[0053] Step 5: Evaporate the solvent at 75°C for 160 minutes to obtain a viscou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com