Oligo cation for co-coagulation of rubber latex and montmorillonite suspension liquid

A polycation and rubber latex technology, applied in the field of flocculants, can solve the problems of low apparent density, flying, and high energy consumption in mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

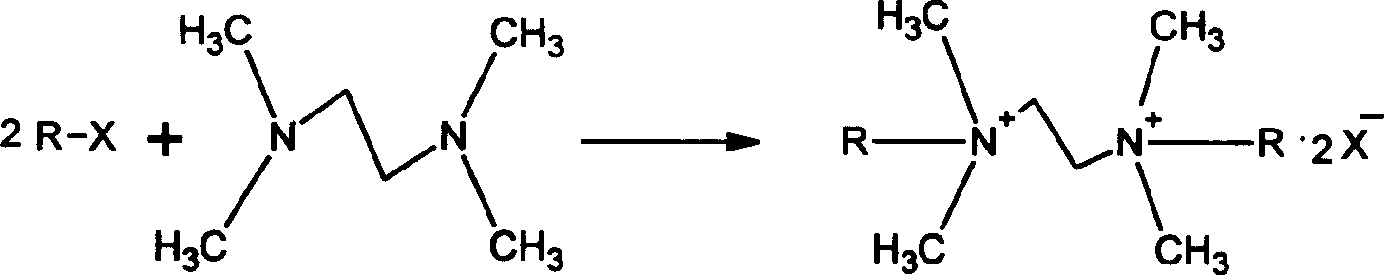

[0020] In a 250ml three-necked flask, 5.8g of N,N'-tetramethylethylenediamine was added, and 100ml of absolute ethanol solution was added to dissolve it. Then add 33.5 g of excess 10% hexadecane bromide and raise the temperature to 70-80° C. for reflux reaction for 48 hours, then cool and crystallize at 0° C., and obtain white crystals by suction filtration. Prepare the oligomeric cationic surfactant DDA we need. Finally, the prepared surfactant is configured into a 5% aqueous solution.

[0021] Get 10g of montmorillonite and put it into a 500ml flask, then add 300ml of deionized water and stir. Then with 10% Na 2 CO 3 The pH value of the solution was adjusted to about 10, stirred for 24 hours, and left to stand for later use.

[0022] The rubber latex of 300g is mixed with 5% montmorillonite suspension, then its mixed solution is added to 5% DDA solution for flocculation (2% H can be added 2 SO 4 solution assisted flocculation). Then add zinc oxide 5.0, stearic acid 2....

Embodiment 2

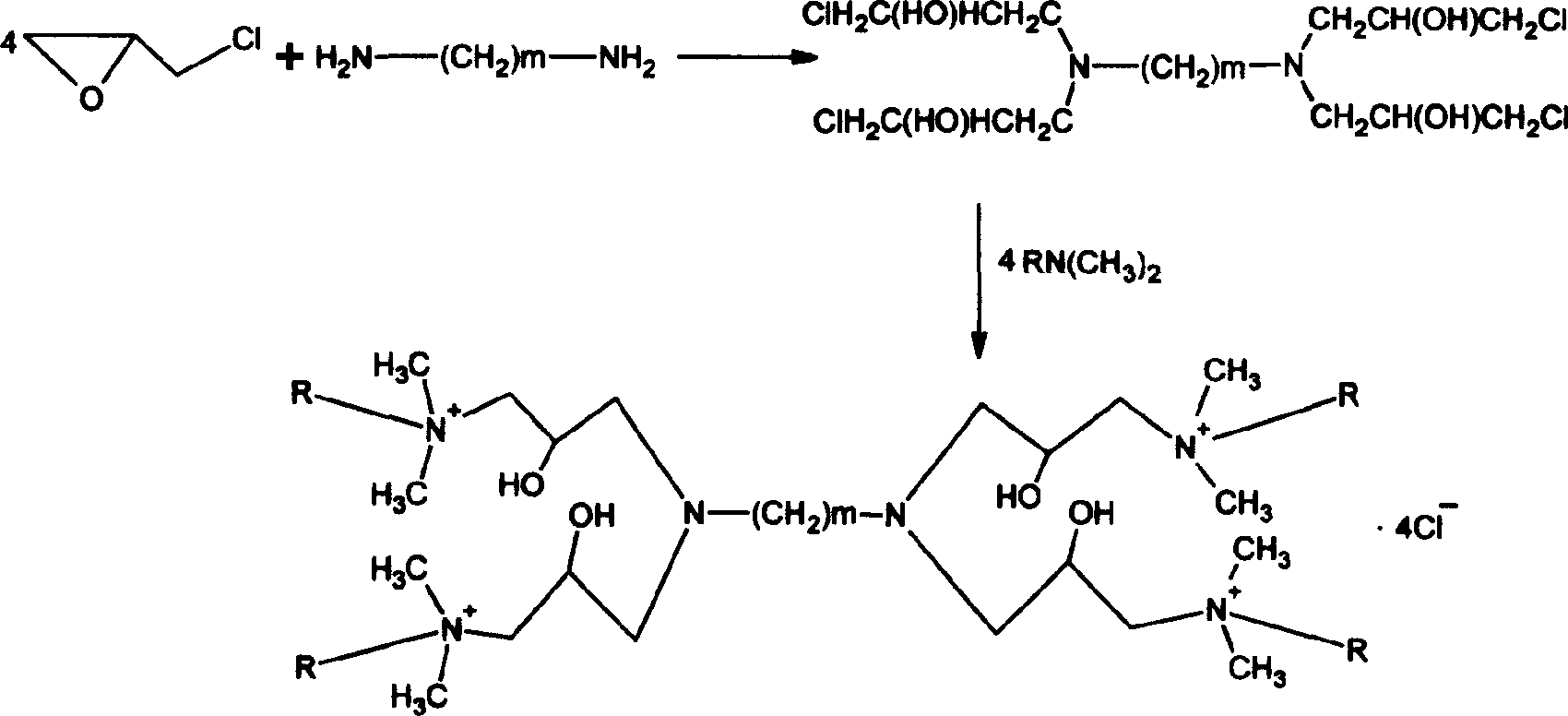

[0024] At a low temperature of 25°C, slowly add epichlorohydrin dropwise to the ethanol solution of ethylenediamine, and ensure that the molar ratio of diamine to epichlorohydrin is 1:4, and the dropping time is about 8 hours. Continue to stir for 24h, then increase the temperature to 40°C, and stir for 5h. Then add a tertiary amine with a saturated alkyl chain therein, and reflux in the ethanol solution for 48 hours. The obtained sample is recrystallized three times with a solvent of m(ethanol):m(acetone)=1. An oligomeric cationic surfactant with four long alkyl chains is obtained.

[0025] Get 10g of montmorillonite and put it into a 500ml flask, then add 300ml of deionized water and stir. Then with 10% Na 2 CO 3 The pH value of the solution was adjusted to about 10, stirred for 24 hours, and left to stand for later use.

[0026] The rubber latex of 300g is mixed with 5% montmorillonite suspension, then its mixed solution is added to 5% solution for flocculation (2% H ca...

Embodiment 3

[0028] At a low temperature of 25°C, slowly add epichlorohydrin dropwise to the ethanol solution of hexamethylenediamine, and ensure that the molar ratio of diamine to epichlorohydrin is 1:4, and the dropping time is about 8 hours. Continue to stir for 24h, then increase the temperature to 40°C, and stir for 5h. Then add a tertiary amine with a saturated alkyl chain therein, and reflux in the ethanol solution for 48 hours. The obtained sample is recrystallized three times with a solvent of m(ethanol):m(acetone)=1. An oligomeric cationic surfactant with four long alkyl chains is obtained.

[0029] Get 10g of montmorillonite and put it into a 500ml flask, then add 300ml of deionized water and stir. Then with 10% Na 2 CO 3 The pH value of the solution was adjusted to about 10, stirred for 24 hours, and left to stand for later use.

[0030] The rubber latex of 300g is mixed with 5% montmorillonite suspension, then its mixed solution is added to 5% solution for flocculation (2%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com