Strain for production of L-serine and method for production of L-serine by using same

A technology of serine and Corynebacterium glutamicum, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problems of difficult process amplification and industrialization, etc., and achieve increased income and stable yield traits , good effect of genetic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Screening of strains with L-serine synthesis ability.

[0028] Collect soil samples below 15cm below the surface around the sugar factory. 1g soil samples are enriched in a conical flask (30mL / 250mL) of enrichment medium containing 50μg / mL nystatin in a reciprocating shaker at 30°C 110rpm / min. The sets were cultured for 3 days. Take 0.1 mL of the enriched bacterial suspension and spread it on the screening medium, use a sterilized filter paper sheet to copy the coated plate to a copy plate, and cultivate for 3 days. Use 0.3% ninhydrin in acetone solution to infiltrate the plate, and dry it at 105°C for 10 minutes to develop the color. Those that produce purple color circles are amino acid producing bacteria.

[0029] Pick the corresponding amino acid-producing bacteria from the copy plate, and perform preliminary screening in the fermentation medium by shaking tubes, one tube for each strain. After the cultivation, the content of L-serine in the fermentation...

Embodiment 2

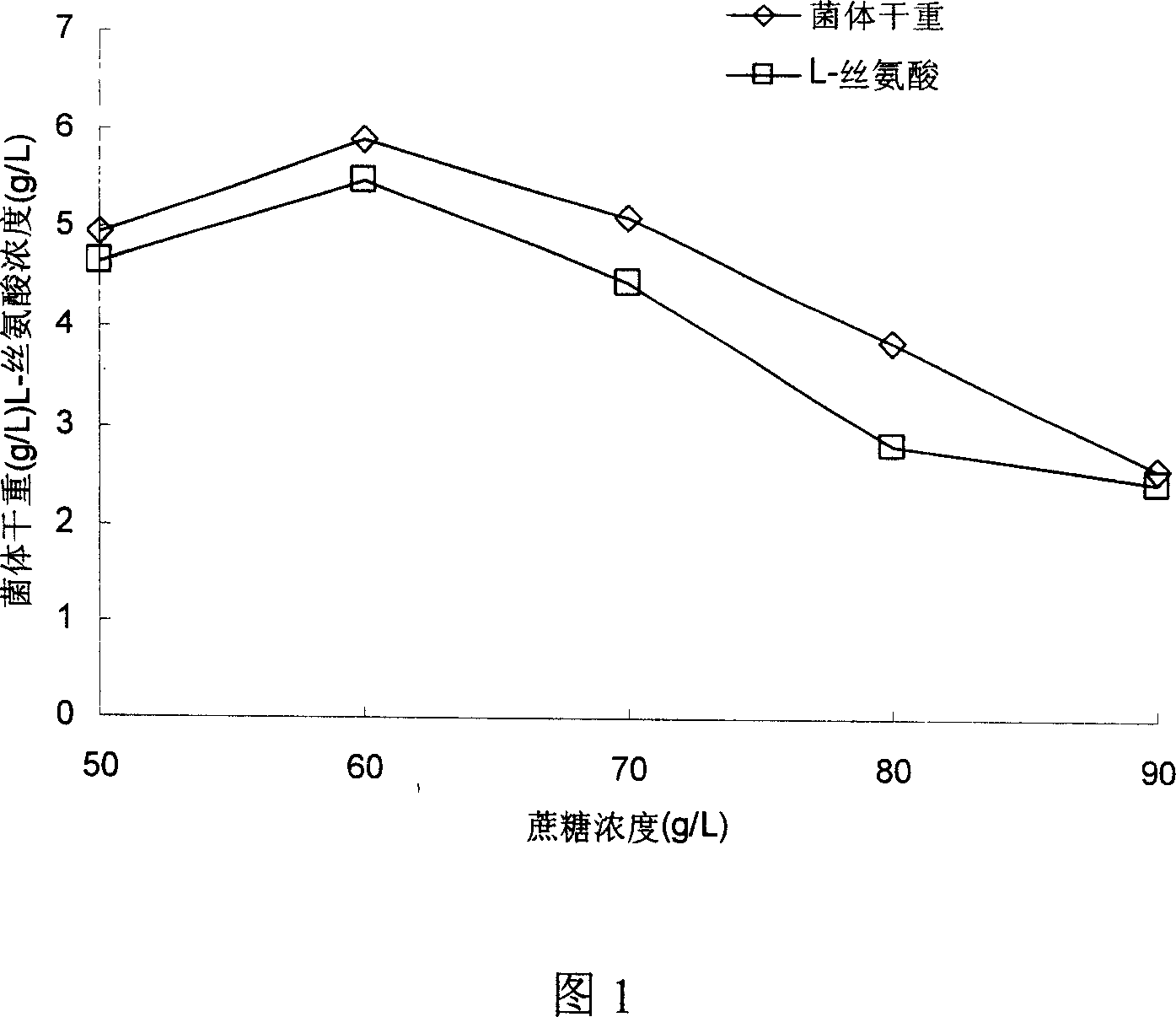

[0034] Embodiment 2 selects the optimum carbon source type and concentration of the fermentation medium.

[0035] Using the fermentation medium in Example 1 as the basal medium, the glucose therein was replaced with carbon sources such as 80 g / L sucrose, fructose, lactose, maltose, starch, etc. The results are shown in Table 2. When glucose, sucrose or fructose were used as carbon sources, the yield of L-serine was higher; when lactose, maltose, and soluble starch were used as the only carbon sources, almost no L-serine was produced. Among them, when sucrose was used as carbon source, the yield of L-serine was the highest, which was 5.1g / mL.

[0036] Carbon source (80g / L)

L-serine (g / L)

Residual sugar (g / L)

Conversion rates(%)

glucose

sucrose

soluble starch

2.9

5.1

3.3

0

0

0

21.6

17.2

19.3

43.2

41.2

19.4

5.87

8.12

5.4

0

0

0

...

Embodiment 4

[0039] Example 4 VB 1 It has a great influence on bacterial growth and L-serine accumulation.

[0040] In the fermentation medium: sucrose 60g / L, corn steep liquor 10-30g / L, cottonseed powder 10-30g / L, (NH 4 ) 2 SO 4 20~50g / L,KH 2 PO 4 1.0~2.0g / L, MgSO 4 ·7H 2 O 0.5~1.0g / L, FeSO 4 ·7H 2 O 0.01~0.05g / L, MnSO 4 ·H 2 O 0.01~0.05g / L, biotin 0.08~0.15mg / L, CaCO 3 On the basis of 20g / L, add 50μg / L, 200μg / L, 500μg / L, 800μg / L of VB 1 , the ventilation rate of the fermenter is 2-3vvm, the stirring speed is 400-600 rpm, and the pH of the culture is within the range of 6-8. The results showed that 500μg / L was the optimal concentration, and the yield of L-serine could reach 6.0-6.4g / L. with and without VB 1 A comparative increase of about 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com