Prepn process of periodic nanometer titania line

A titanium dioxide and nanowire technology, which is applied in the directions of titanium dioxide, nanostructure manufacturing, titanium oxide/hydroxide, etc., can solve the problems of long constant temperature time, inconvenient operation, large amount of medicine and solvent, etc., and achieves a simple and easy preparation method. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

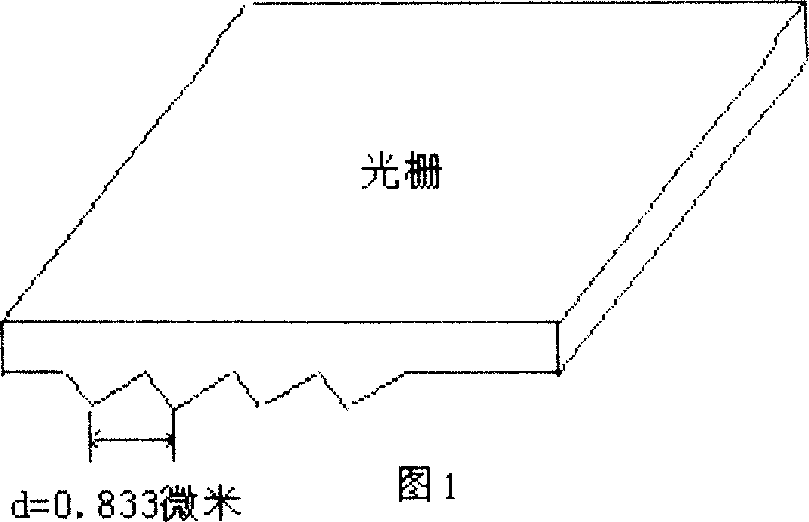

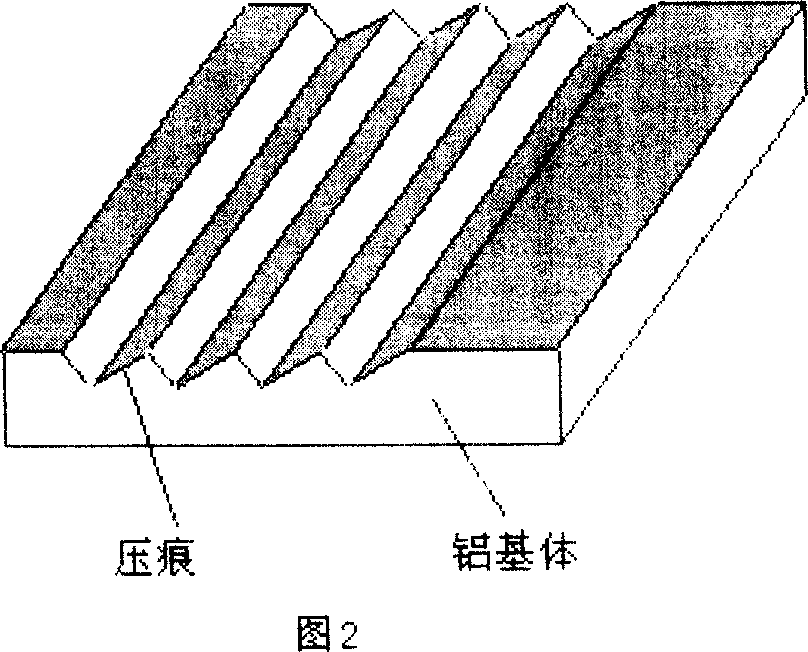

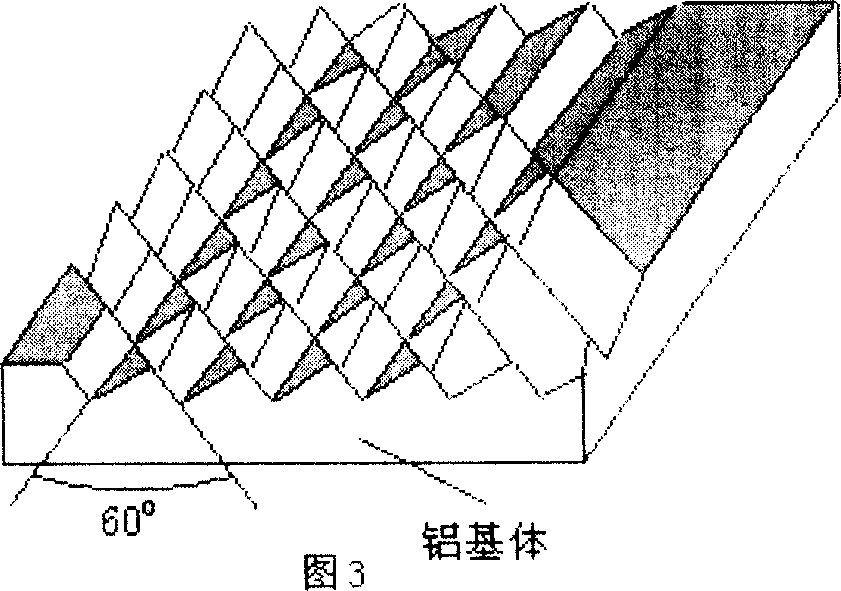

[0031] In the first step, the size of the aluminum sheet is 20mm*20mm, annealed at 500°C for 5 hours, the polishing temperature is 4°C, and the polishing time is 40 seconds; in the second step, the aluminum sheet treated in the first step is placed in a concentration In the phosphoric acid solution of 0.1mol / L, at 0°C, carry out the first anodic oxidation, the current of anodic oxidation is 10mA, and the anodic oxidation time is 3 hours; in the fourth step, the grating density and grating period are respectively 1200 mm line and 0.833 micron reflective grating; in the sixth step, the composition of liquid A is the volume ratio=1:4:1 of tetrabutyl titanate 5mL, absolute ethanol 20mL and glacial acetic acid 5mL, and the composition of liquid B The volume ratio of absolute ethanol 10mL and deionized water 1mL=10:1; in the seventh step, adjust the pH value of the sol to 2; in the eighth step, put the template obtained in the fifth step in boiling absolute ethanol Boil for 8 minute...

Embodiment 2

[0033] In the first step, the size of the aluminum sheet is 20mm*20mm, annealed at 560°C for 5 hours, the polishing temperature is 7°C, and the polishing time is 30 seconds; in the second step, the aluminum sheet treated in the first step is placed in a concentration In the phosphoric acid solution of 0.3mol / L, at 4°C, carry out the first anodic oxidation, the anodic oxidation current is 5.5mA, and the anodic oxidation time is 5.5 hours; in the fourth step, the grating density and grating period are respectively Reflective grating with 1200 lines per millimeter and 0.833 micron; in the sixth step, the composition of liquid A is the volume ratio=1:4:1 of tetrabutyl titanate 5mL, absolute ethanol 20mL and glacial acetic acid 5mL, and the volume ratio of liquid B The composition is the volume ratio of 10 mL of absolute ethanol and 1 mL of deionized water = 10:1; in the seventh step, adjust the pH value of the sol to 3; in the eighth step, put the template obtained in the fifth ste...

Embodiment 3

[0035] In the first step, the size of the aluminum sheet is 20mm*20mm, annealed at 620°C for 5 hours, the polishing temperature is 10°C, and the polishing time is 20 seconds; in the second step, the aluminum sheet treated in the first step is placed in a concentration In the phosphoric acid solution of 0.5mol / L, at 8°C, carry out the first anodic oxidation, the anodic oxidation current is 1mA, and the anodic oxidation time is 8 hours; in the fourth step, the grating density and grating period are respectively 1200 mm line and 0.833 micron reflective grating; in the sixth step, the composition of liquid A is the volume ratio=1:4:1 of tetrabutyl titanate 5mL, absolute ethanol 20mL and glacial acetic acid 5mL, and the composition of liquid B The volume ratio of absolute ethanol 10mL and deionized water 1mL=10:1; in the seventh step, adjust the pH value of the sol to 4; in the eighth step, put the template obtained in the fifth step in boiling absolute ethanol Boil for 12 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com