Avermectins long-effective slow-release oil suspension agent and preparing method

A technology of abamectin and oil suspension, which is applied in the field of abamectin long-acting slow-release oil suspension and its preparation, can solve the problems of environmental pollution, non-biodegradable, etc., and achieve pollution reduction, pesticide cost reduction and , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

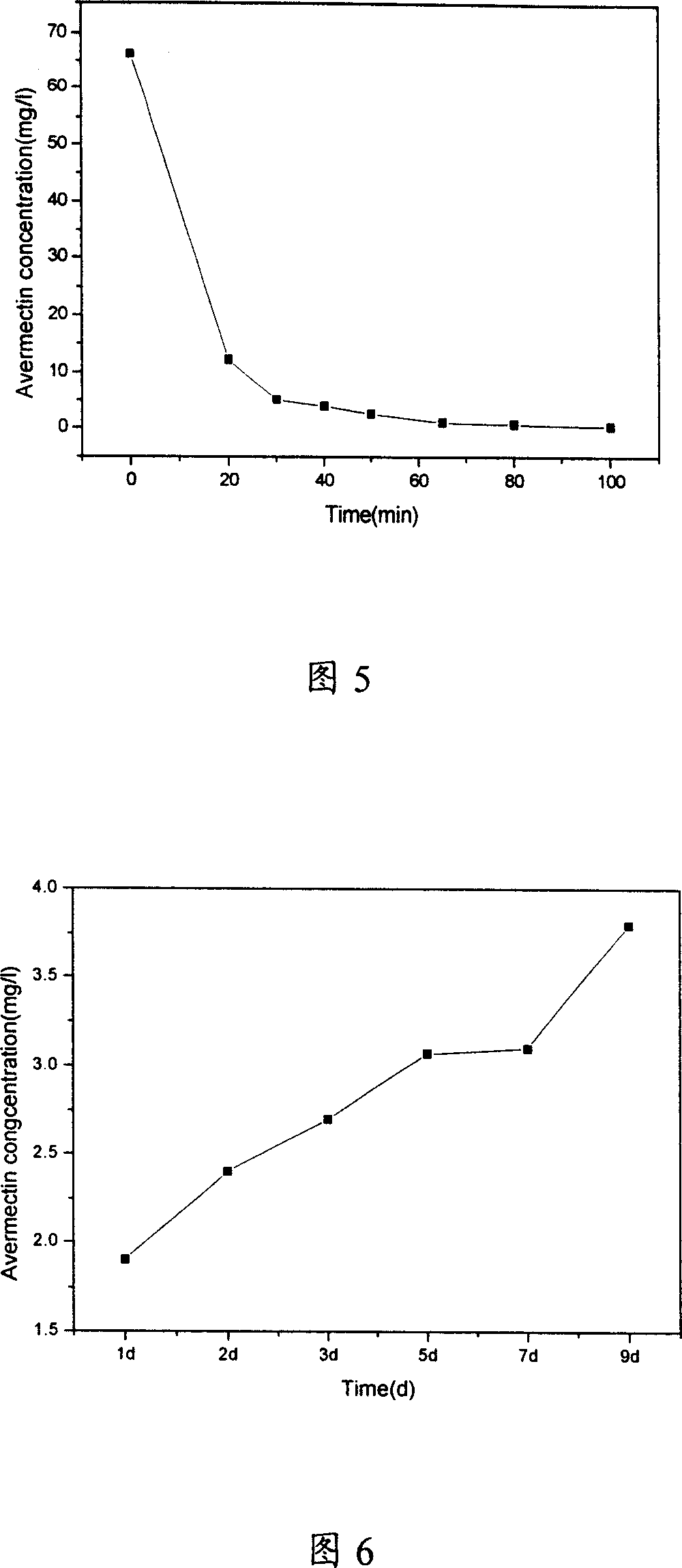

[0058] Embodiment 1: 1.8% Abamectin long-acting slow-release oil suspension

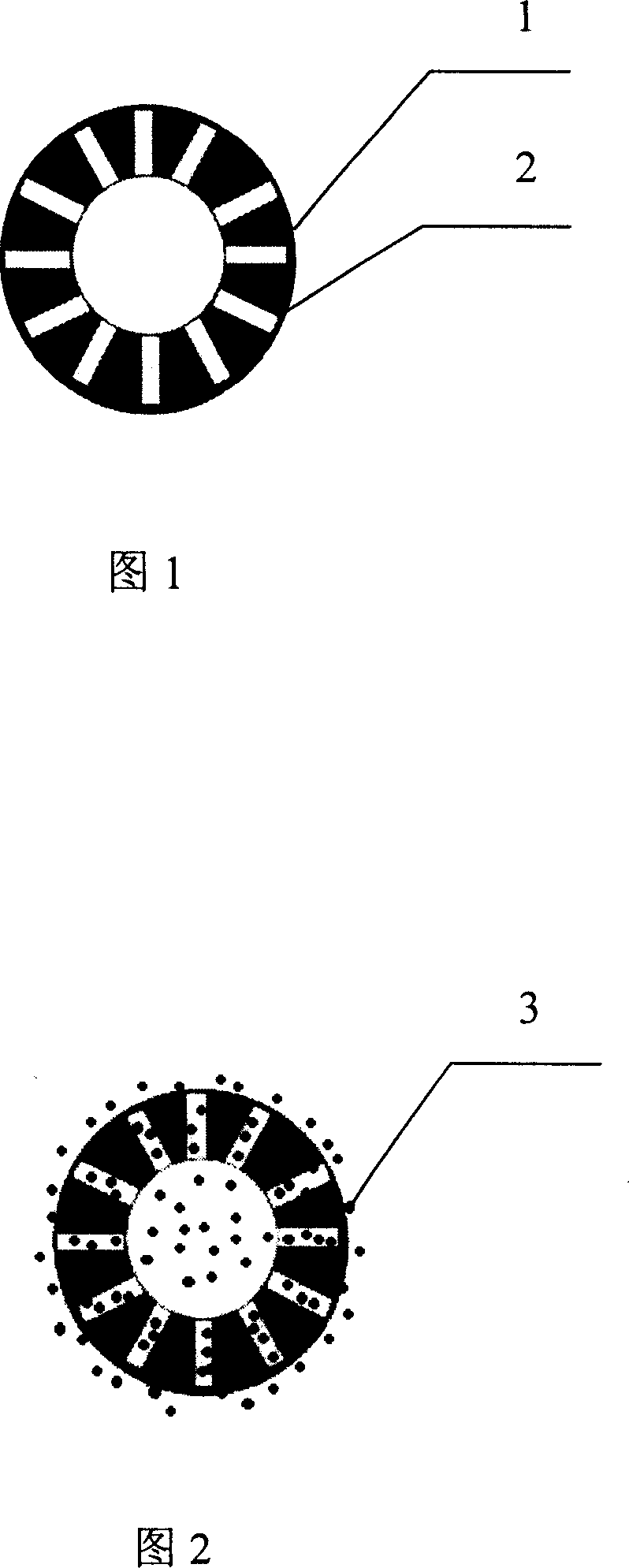

[0059] Prepare the nano-calcium carbonate suspension (concentration is determined by volumetric analysis) with a mass percentage concentration of 8%, and set it aside. Measure 500 mL of the suspension, and add 10 g of cationic surfactant cetyltrimethylammonium bromide (CTAB), mix with the calcium carbonate suspension and disperse evenly. Accurately prepare a sodium silicate solution containing 1% silicon dioxide, measure 300 mL of sodium silicate solution, so that the mass percentage of silicon dioxide / calcium carbonate in the suspension is 15%. The temperature of the suspension is raised to 80°C, and the sodium silicate solution is evenly added to the calcium carbonate suspension within 2 hours, and the pH is adjusted and maintained at about 12 with hydrochloric acid with a mass percentage of 10%, and the addition is completed and aged for 2 hours. It is suction filtered, dried at a temperature of ...

Embodiment 2

[0061] Embodiment 2: 1.8% Abamectin long-acting slow-release oil suspension

[0062] Prepare the nano-calcium carbonate suspension (concentration is determined by volumetric analysis) with a mass percentage concentration of 8%, and set it aside. Measure 500 mL of the suspension, and add 10 g of cationic surfactant cetyltrimethylammonium bromide (CTAB), mix with the calcium carbonate suspension and disperse evenly. Accurately prepare a sodium silicate solution containing 2% silica, and measure 400 mL of the sodium silicate solution so that the mass percentage of silica / calcium carbonate in the suspension is 40%. The temperature of the suspension is raised to 80°C, and the sodium silicate solution is evenly added to the calcium carbonate suspension within 2 hours, and the pH is adjusted and maintained at about 12 with hydrochloric acid with a mass percentage of 10%, and the addition is completed and aged for 2 hours. It is suction filtered, dried at a temperature of 100°C, and ...

Embodiment 3

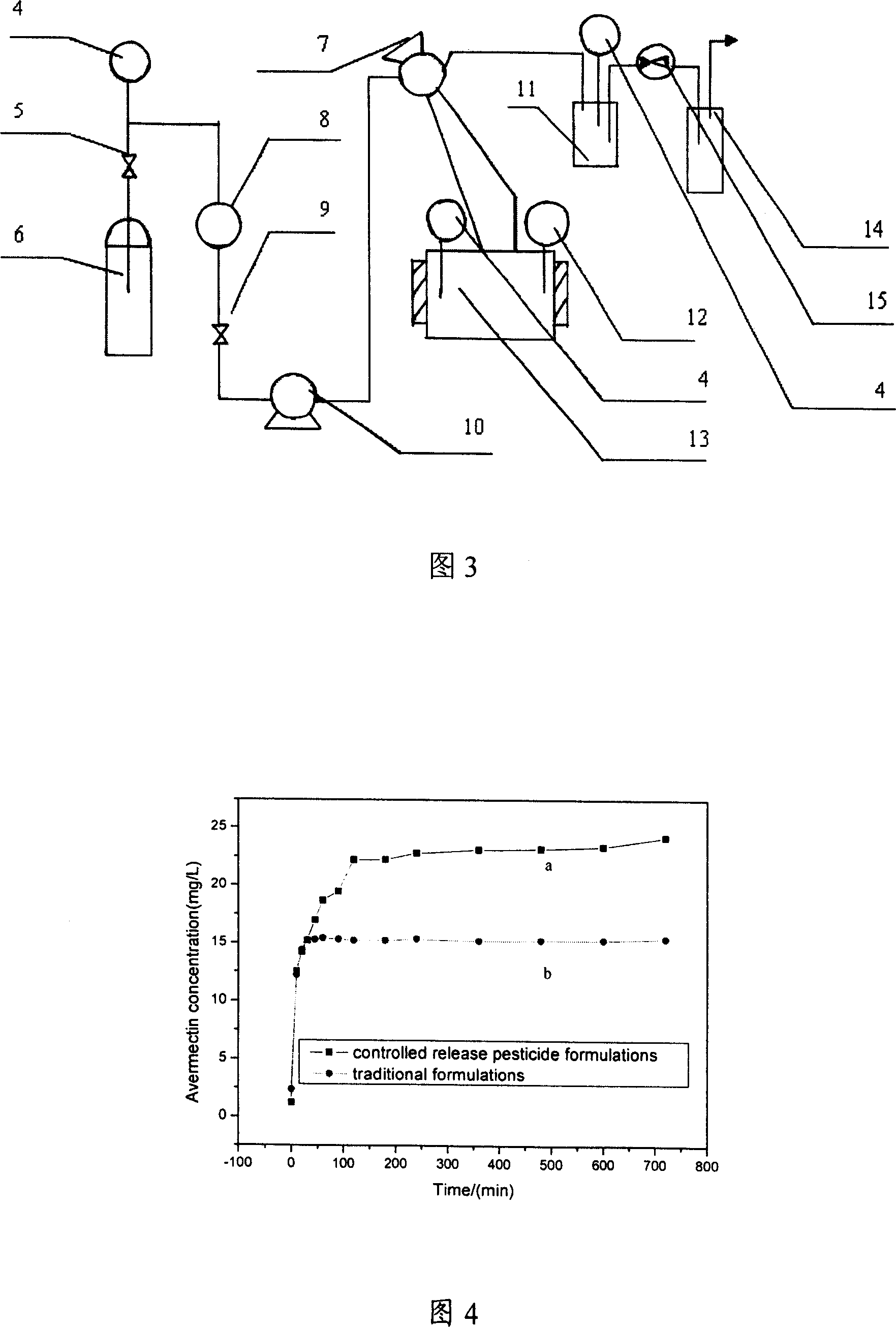

[0064] Embodiment 3: 4% Abamectin long-acting slow-release oil suspension

[0065] 5.0g Abamectin is dissolved in 15mL acetone solvent, is made into the Abamectin acetone solution of 0.33g / mL, stand-by; Take by weighing the hollow porous nano-SiO of 5.0g embodiment 1 2 The controlled-release carrier was activated for 8 hours at a temperature of 100°C and a vacuum of 0.1 MPa; the activated hollow porous SiO 2 Nanoparticles were added to the prepared 0.33g / mL abamectin acetone solution, placed in a high-pressure embedding device, embedded for 6 hours under the supercritical conditions of pressure 20.0MPa and temperature 40°C, and the samples were dried. The hollow porous nano-SiO with 40.0% abamectin embedded 2 Carrier mixture, ready for use; weigh 10g of abamectin nano-controlled release agent and 40.2g of isopropanol and put them into a ball mill for ball milling, pulverize until the average particle size of the particles is less than 60 microns, and then add 25g of emulsifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com