Preparing process of nickel hydroxide film in nano structure

A technology of nickel hydroxide and nanostructure, which is applied in the field of nanomaterials to achieve the effects of low cost, simple experimental conditions, and simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

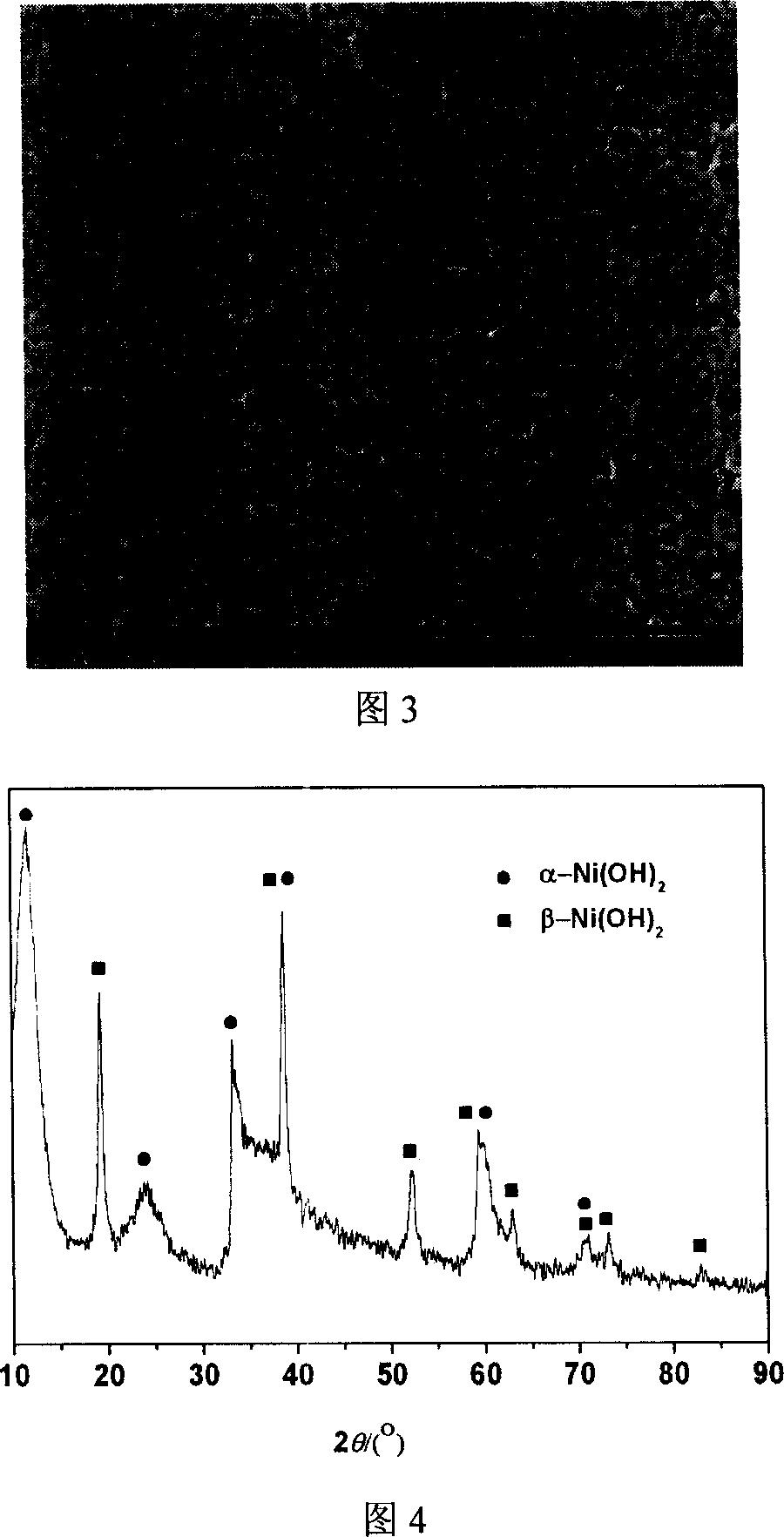

example 1

[0027] In Example 1, the glass slide was used as a substrate, and before being immersed in the reaction solution, it was ultrasonically washed with dilute nitric acid and ethanol for 30 minutes, then rinsed with distilled water, and dried naturally for use. A certain amount of solid NiCl 2 ·6H 2 O was dissolved in 100ml of water to give green NiCl 2 aqueous solution. Wherein, the molar concentration of Ni(II) in the solution is 0.03mol / L. in NiCl 2 Hydrofluoric acid with a mass concentration of 40% was added to the aqueous solution to adjust the atomic ratio of Ni(II) to F in the solution to be 1:3. Then, slowly dropwise add ammonia water with a mass concentration of 25% in the above mixed solution to adjust the pH value of the solution to 8.3. Quickly transfer the configured solution into the reaction container, insert the pre-treated glass slide vertically, and put the reaction container in a water bath at 60°C to stand still. After reacting for 2 hours, take out the g...

example 2

[0029] In Example 2, the glass slide was used as a substrate, and was ultrasonically washed with dilute nitric acid and ethanol for 20 minutes before being immersed in the reaction solution, then rinsed with distilled water, dried naturally, and used. A certain amount of solid NiCl 2 ·6H 2 O was dissolved in 100ml of water to give green NiCl 2 aqueous solution. Wherein, the molar concentration of Ni(II) in the solution is 0.03mol / L. in NiCl 2 Hydrofluoric acid with a mass concentration of 40% was added to the aqueous solution to adjust the atomic ratio of Ni(II) to F in the solution to be 1:3. Then, slowly dropwise add ammonia water with a mass concentration of 25% in the above mixed solution to adjust the pH value of the solution to 8.8. Quickly transfer the configured solution into the reaction container, insert the pre-treated glass slide vertically, and put the reaction container in a water bath at 60°C to stand still. After reacting for 2 hours, take out the glass s...

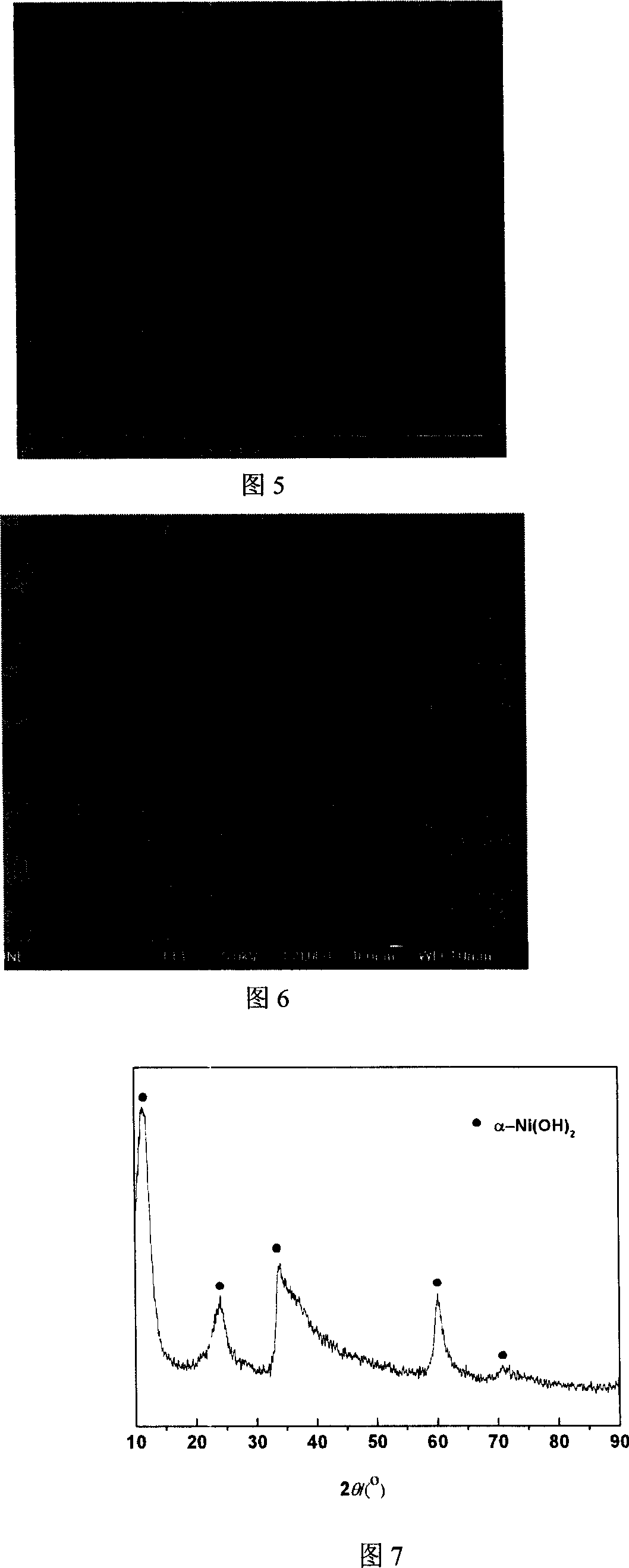

example 3

[0031] In Example 3, the glass slide was used as a substrate, and was ultrasonically washed with dilute nitric acid and ethanol for 40 minutes before being immersed in the reaction solution, then rinsed with distilled water, dried naturally, and ready for use. A certain amount of solid NiCl 2 ·6H 2 O was dissolved in 100ml of water to give green NiCl 2 aqueous solution. Wherein, the molar concentration of Ni(II) in the solution is 0.03mol / L. in NiCl 2 Hydrofluoric acid with a mass concentration of 40% was added to the aqueous solution to adjust the atomic ratio of Ni(II) to F in the solution to be 1:6. Then, slowly dropwise add ammonia water with a mass concentration of 25% in the above mixed solution to adjust the pH value of the solution to 8.0. Quickly transfer the configured solution into the reaction container, insert the pre-treated glass slide vertically, and put the reaction container into a water bath at 80°C to stand still. After reacting for 2 hours, the glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com